High-resilience hydrogen-containing silicone oil and preparation method thereof

A technology of high hydrogen-containing silicone oil and hydrogen-containing silicon, applied in the chemical industry, can solve the problems of non-compliance of VOC detection, complex and changeable process flow, poor foam stability, etc., achieving good catalytic effect, strong controllability, The effect of strong foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

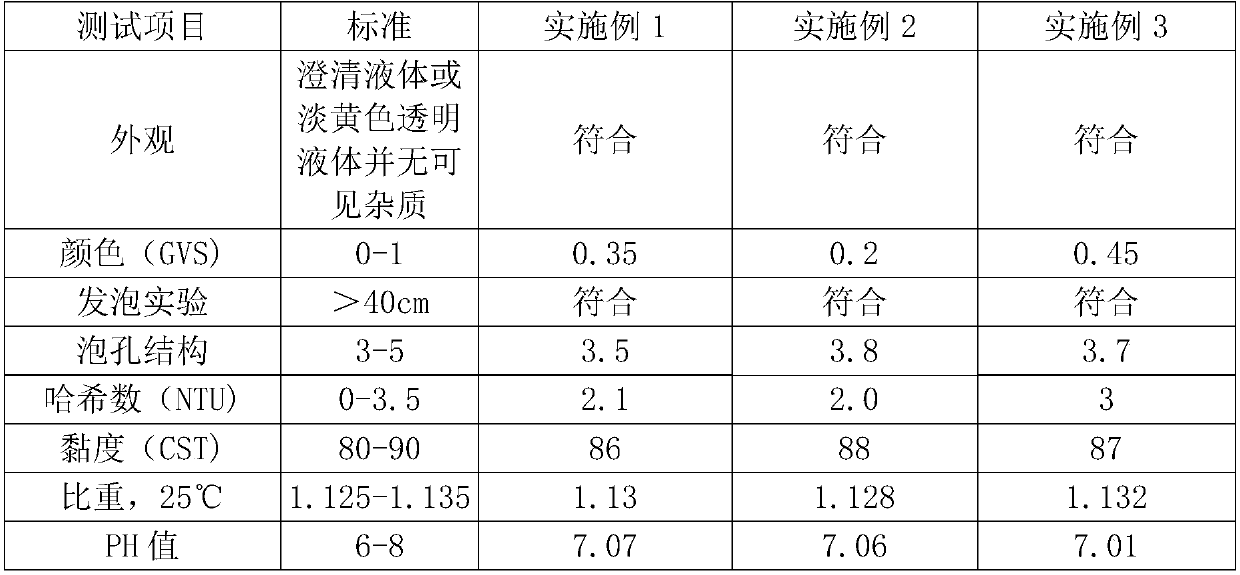

Embodiment 1

[0017] A high-resilience hydrogen-containing silicone oil: D4 65kg, epoxy resin 15kg, 3500 molecular weight polyether 7.5kg, 204 molecular weight polyether 2kg, high hydrogen-containing silicone oil 10.5kg.

[0018] Preparation method: Mix 65kg of D4, 15kg of epoxy resin, 7.5kg of 3500 molecular weight polyether, 2kg of 204 molecular weight polyether, and 10.5kg of high hydrogen-containing silicone oil, stir at a speed of 30 rpm for 80 minutes, and heat to 75°C , blow nitrogen, react for 15 hours, until the mixed liquid becomes clear, until the detected hydrogen content of the mixed liquid meets 0.75-1.3%, and the hydrogen-containing viscosity is 80-90CTS, that is. The hydrogen content of this embodiment is 0.8%, and the hydrogen viscosity is 86CST.

Embodiment 2

[0020] A high resilience hydrogen-containing silicone oil: D4 63kg, epoxy resin 12kg, 3500 molecular weight polyether 11kg, 204 molecular weight polyether 5kg, high hydrogen-containing silicone oil 9kg.

[0021] Preparation method: Mix 63kg of D4, 12kg of epoxy resin, 11kg of 3500 molecular weight polyether, 5kg of 204 molecular weight polyether, and 9kg of high hydrogen-containing silicone oil, stir at 33 rpm for 85 minutes, heat to 73°C, and pass Nitrogen, react for 17 hours, until the mixed liquid becomes clear, until the detected hydrogen content of the mixed liquid meets 0.75-1.3%, and the hydrogen-containing viscosity is 80-90CST, that is. The hydrogen content of this embodiment is 0.85%, and the hydrogen viscosity is 88CST.

Embodiment 3

[0023] A high resilience hydrogen-containing silicone oil: D4 60kg, epoxy resin 30kg, 3500 molecular weight polyether 3kg, 204 molecular weight polyether 2kg, high hydrogen-containing silicone oil 5kg.

[0024] Preparation method: Mix 60kg of D4, 30kg of epoxy resin, 3kg of 3500 molecular weight polyether, 2kg of 204 molecular weight polyether, and 5kg of high hydrogen-containing silicone oil, stir at 40 rpm for 100 minutes, heat to 75°C, and pass Nitrogen, react for 18 hours, until the mixed liquid becomes clear, until the detected hydrogen content of the mixed liquid meets 0.75-1.3%, and the hydrogen-containing viscosity is 80-90CST, that is to say. The hydrogen content of this embodiment is 0.9%, and the hydrogen viscosity is 87CST.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com