Heat treatment method of high-temperature-resisting alloy material and heat treatment material

A technology of high temperature resistant alloy and heat treatment method, applied in the field of material processing, can solve the problem that the iron-nickel alloy cannot meet the application and other problems, and achieve the effects of avoiding personnel burn accidents, powerful functions, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

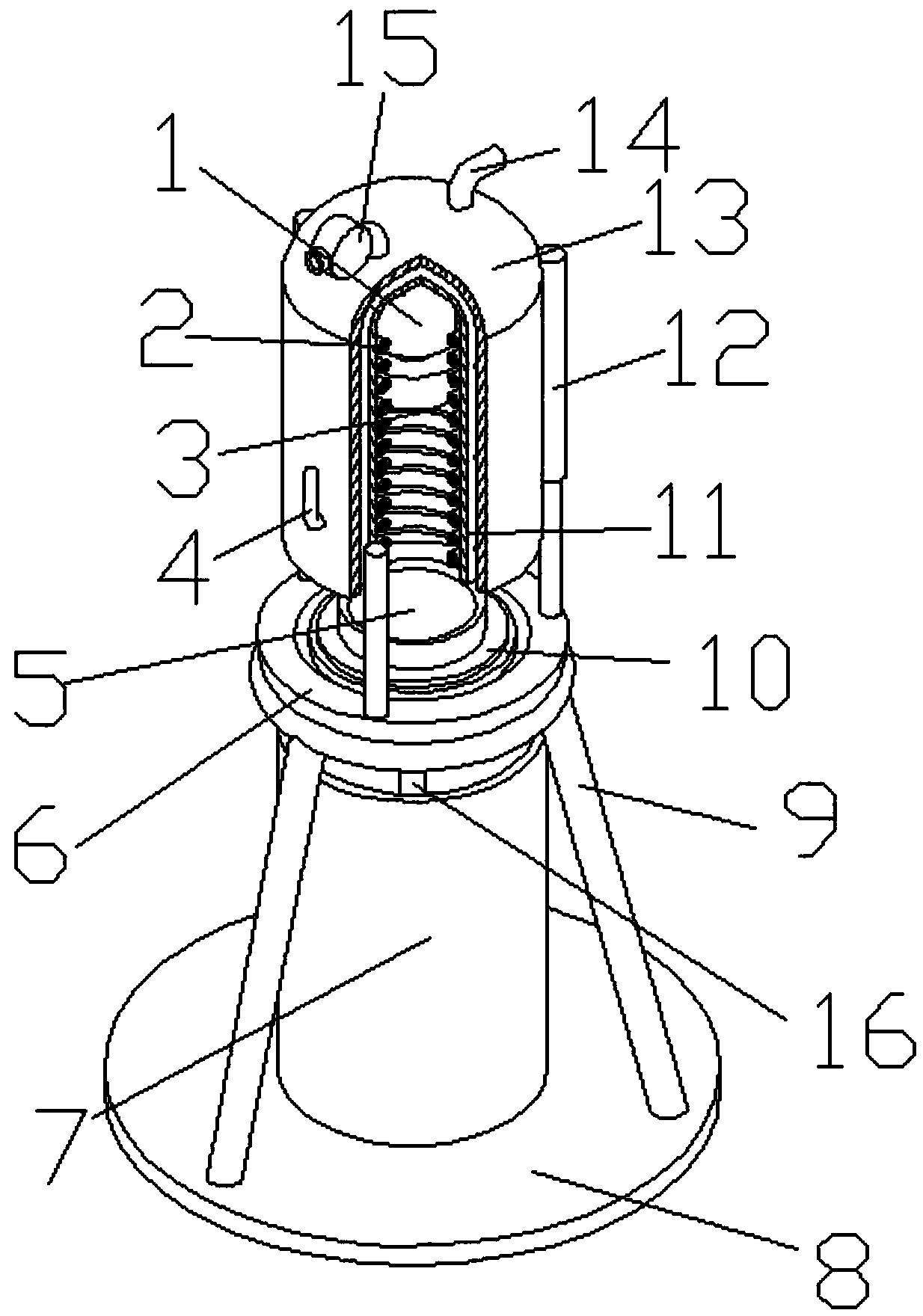

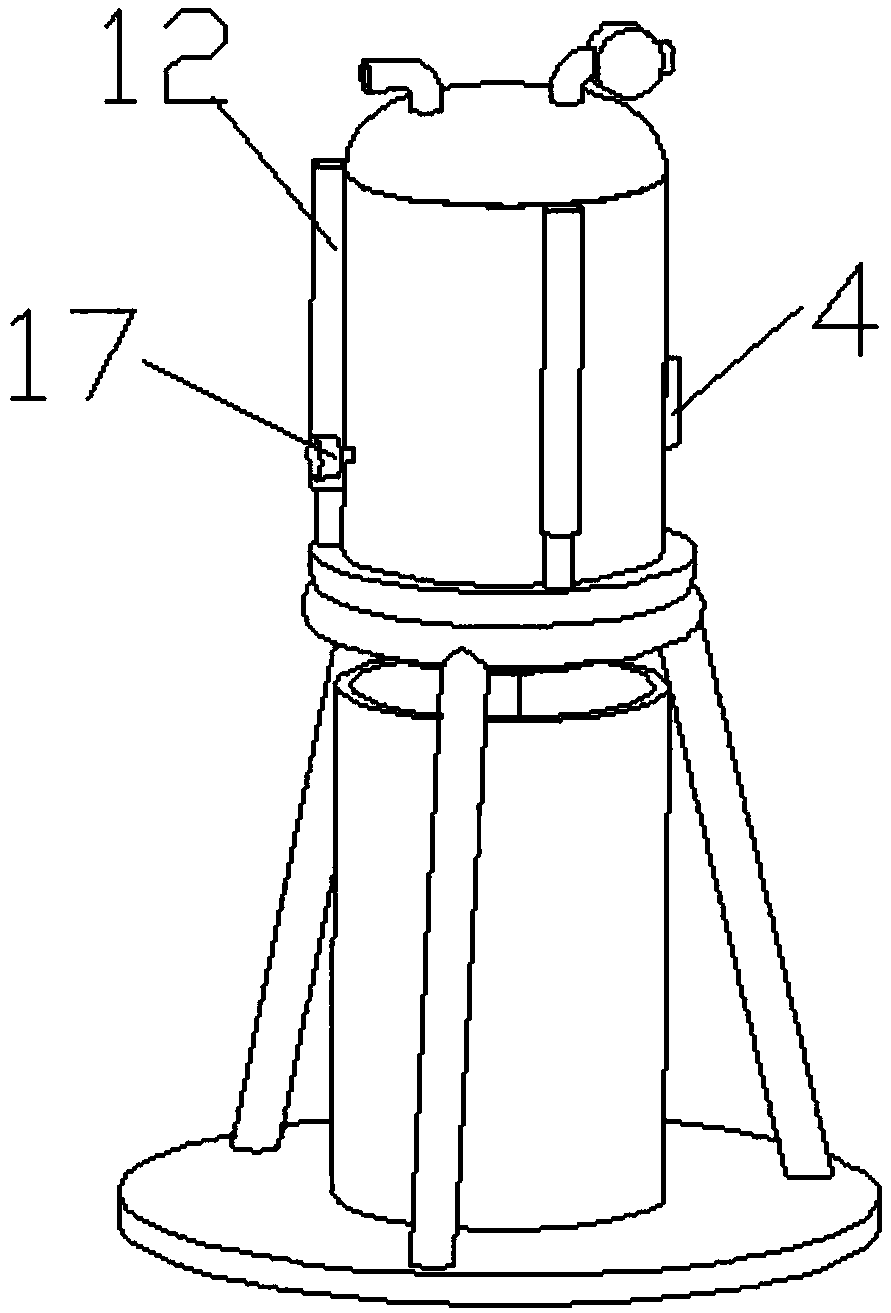

Image

Examples

Embodiment 1

[0039] A kind of heat treatment method of high temperature resistant alloy material, described heat treatment step is specifically as follows:

[0040] Step 1. Put the high temperature resistant alloy material into the furnace, and use a vacuum pump to evacuate the inside of the furnace to vacuum;

[0041] Step 2. Adjust the temperature of the furnace so that the temperature of the furnace rises slowly to approximately 989°C;

[0042] Step 3. Slowly heat the high temperature resistant alloy material to about 989°C, keep it warm for 5 hours, and then let the high temperature resistant alloy material slowly cool;

[0043] Step 4. Slowly heat the high temperature resistant alloy material to about 790°C, then keep it warm for 10 hours, and then slowly cool the high temperature resistant alloy material;

[0044] Step 5. Slowly heat the high temperature resistant alloy material to about 740°C, then keep it warm for 25 hours, and then slowly cool the high temperature resistant alloy...

Embodiment 2

[0054] A kind of heat treatment method of high temperature resistant alloy material, described heat treatment step is specifically as follows:

[0055] Step 1. Put the high temperature resistant alloy material into the furnace, and use a vacuum pump to evacuate the inside of the furnace to vacuum;

[0056] Step 2. Adjust the temperature of the furnace so that the temperature of the furnace rises slowly to about 970°C;

[0057] Step 3. Slowly heat the high temperature resistant alloy material to about 970°C, keep it warm for 5 hours, and then let the high temperature resistant alloy material slowly cool;

[0058] Step 4: Slowly heat the high-temperature-resistant alloy material to about 780°C, then keep it warm for 5 hours, and then slowly cool the high-temperature-resistant alloy material;

[0059] Step 5. Slowly heat the high temperature resistant alloy material to about 700°C, then keep it warm for 10 hours, and then slowly cool the high temperature resistant alloy material...

Embodiment 3

[0078] The iron-nickel alloy that embodiment 1-2 and comparative example 1-3 heat treatment obtains carries out fracture stress test:

[0079] Put the iron-nickel alloy obtained by heat treatment in Example 1-2 and Comparative Example 1-3 into a press, and then heat it to 600°C, pressurize the iron-nickel alloy at the same time, observe the corresponding stress at the time of fracture, repeat for each group of samples Test 5 times, get the average value of the experimental results, the results are shown in Table 1;

[0080] The iron-nickel alloy fracture stress test result that table 1 embodiment 1-2 and comparative example 1-3 heat treatment obtain

[0081] material object

[0082] As can be seen from Table 1, the breaking stress of Example 1 is slightly reduced compared with Comparative Example 3, the breaking stress of Example 2 is slightly increased compared with Comparative Example 3, and the breaking stress of Comparative Example 1 is compared with Comparative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com