Carrier plate and film coating equipment

A technology of coating equipment and carrier board, which is applied in the field of coating equipment, can solve the problems of silicon wafers being affected by air exposure, mechanical damage on the surface of silicon wafers, complicated and time-consuming problems, so as to avoid the influence of air exposure, reduce the probability of pollution, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

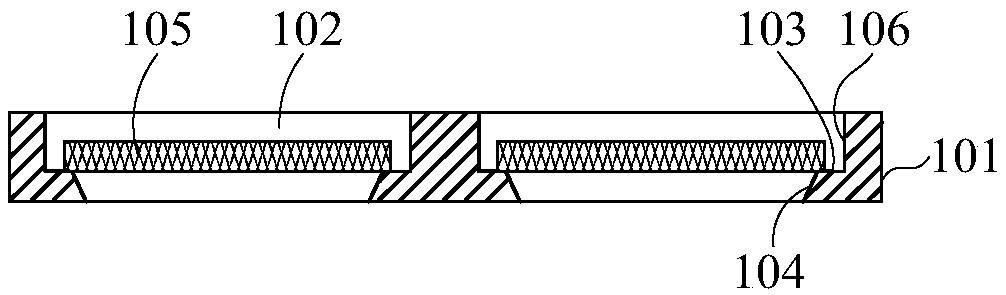

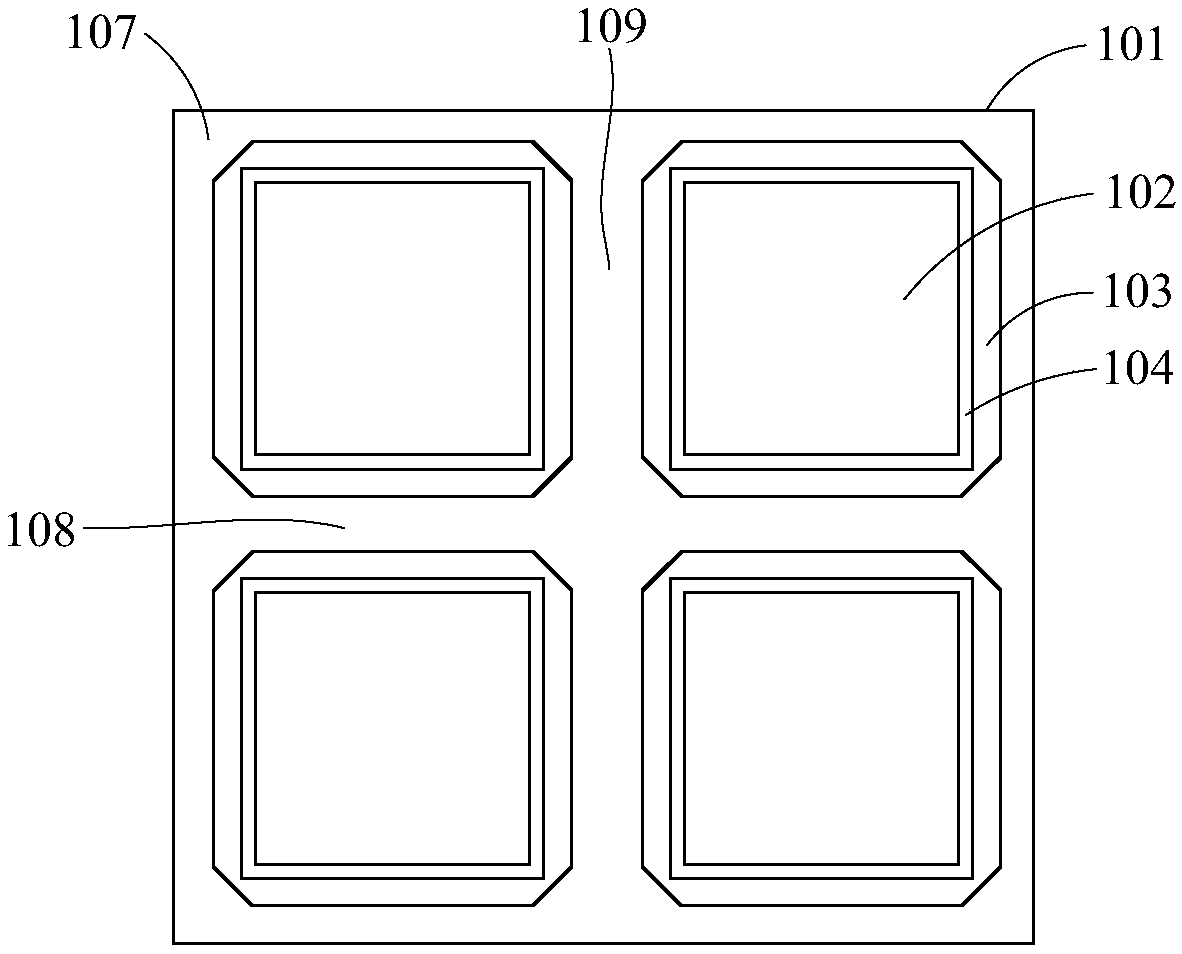

[0036] Such as Figure 1-Figure 4 As shown, the present embodiment provides a carrier 101 for carrying a silicon chip 105 (or other types of substrates), the carrier 101 is provided with at least one hollow groove 102, and each hollow groove 102 is provided with a support member So that the component to be processed (silicon wafer 105 ) can be placed in the hollow groove 102 .

[0037] Wherein, the size of the hollow groove 102 should match the size of the silicon wafer 105 placed therein. For example, most of the existing solar cells are octagonal, so the silicon wafers used to prepare the solar cells should also be octagonal. Correspondingly, the hollow groove can also be quadrangular or octagonal or other shapes, and the size of the hollow groove needs to be slightly larger than the silicon chip, so that the silicon chip can be put into it.

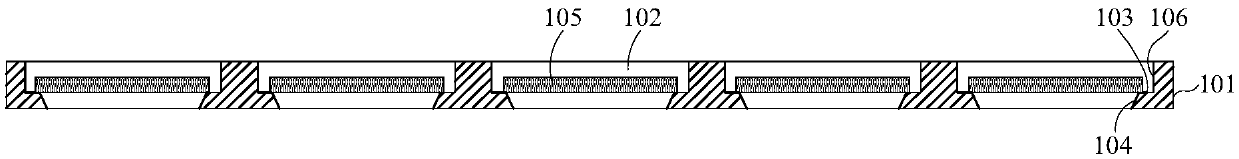

[0038] In this embodiment, after each silicon chip 105 (or other type of substrate) is placed in each hollow groove 102 on the carri...

Embodiment 2

[0066] Such as Figure 5-Figure 8 As shown, the present embodiment provides a coating device for coating a substrate (such as a silicon wafer), which includes: a coating chamber 200, and a driving device (not shown in the figure) arranged outside the coating chamber 200 , and the carrier plate 101 as described in Embodiment 1 disposed inside the coating chamber 200 .

[0067] Wherein, the interior of the coating chamber 200 is divided into a plurality of coating areas, and the top or bottom of each coating area is provided with a target installation position, and the corresponding target can be installed at the required position according to the needs of the coating, and the target is preferably a rolling target. . Each target can be controlled separately. Any two different targets can be made of the same material or different materials. For example, when the two targets are metal targets of different materials, an alloy film can be prepared. By modulating the magnetron The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com