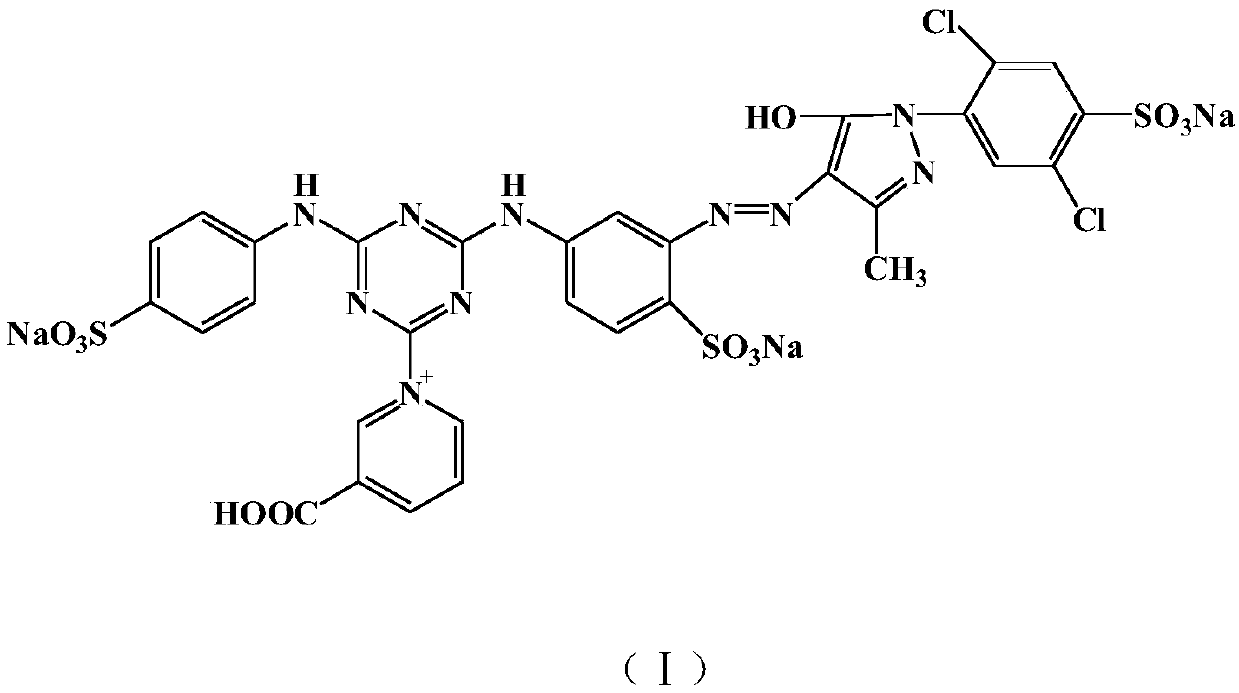

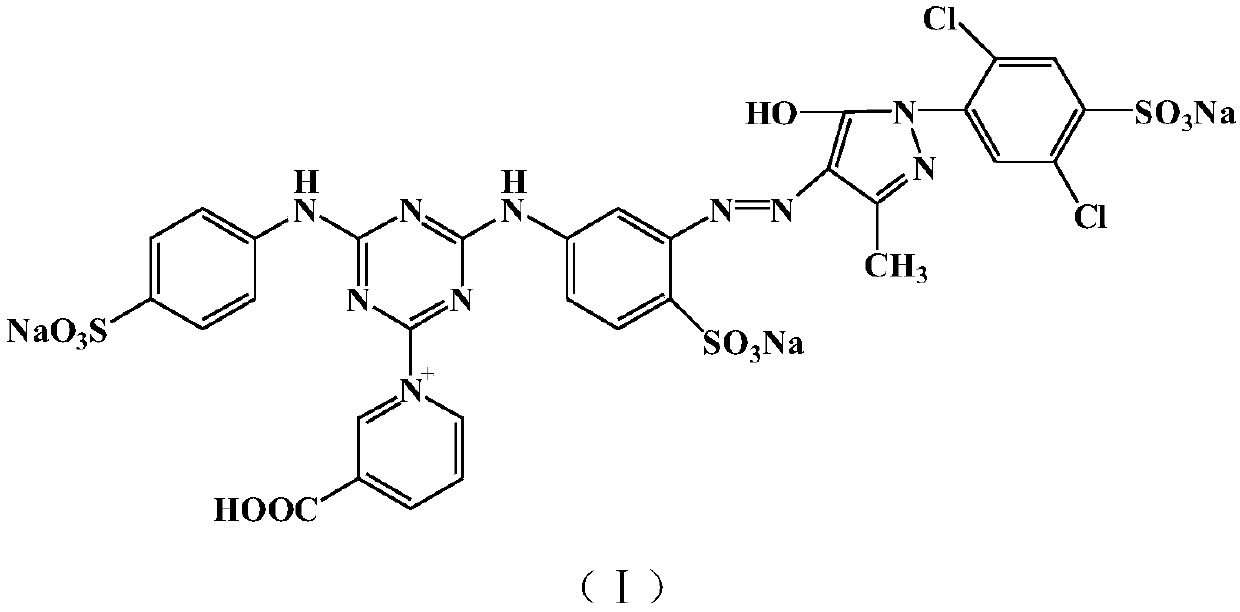

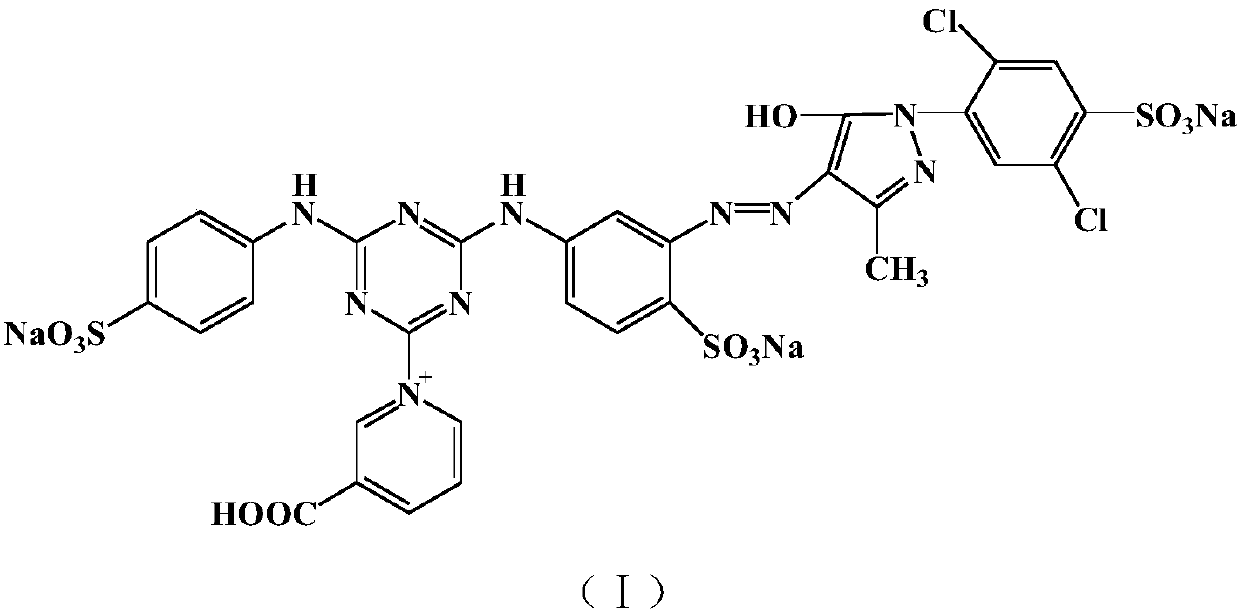

Reactive dye

A technology of reactive dyes and viscose fibers, which is applied in the field of textile dyes, can solve the problems of accelerated hydrolysis of reactive dyes, environmental pollution around printing and dyeing factories, unfavorable growth of surrounding trees and crops, etc., achieves good dyeing performance, is conducive to environmental protection, and saves The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present embodiment provides the printing method of formula (I) compound to cotton fabric:

[0014] The dosage of compound (I) is 2%, the dosage of 8% sodium alginate raw paste is 50%, and the rest is water. Hand platen printing, steaming, washing, soaping, washing.

[0015] The washing fastness of printed products is 4-5, and the rubbing fastness is 4-5.

Embodiment 2

[0017] The present embodiment provides the dyeing method of formula (I) compound to cotton fabric:

[0018] The dosage of compound (I) is 2.0% (o.w.f, to the weight of the fabric), the bath ratio is 1:50, dyeing at room temperature, 15g / L of Canadian sodium starch powder, 2°C / min heating to 100°C, keeping it warm for 60min, finishing dyeing, washing with water, Soap, wash.

[0019] The washing fastness of dyed products is grade 4-5, and the rubbing fastness is grade 4-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com