Method for coordinating and controlling steam pipe network and gas pipe network of metallurgical gas boilers

A gas-fired boiler and gas pipe network technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of energy waste, affecting production safety, high pressure of gas pipe network, etc., to improve accuracy and stability performance, reduce labor intensity, and continuously and stably generate power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

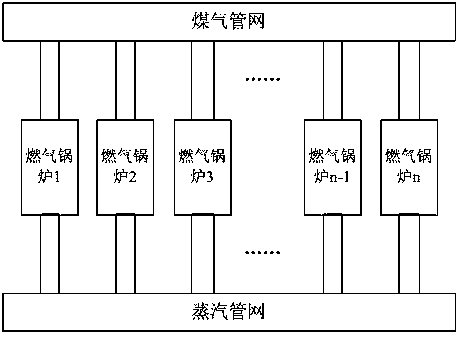

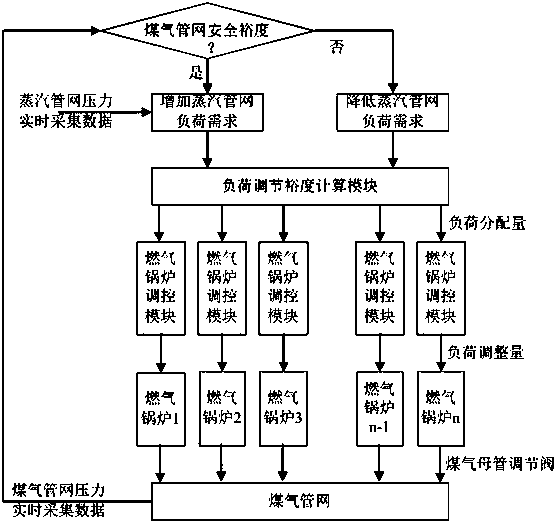

[0019] Such as figure 2 As shown, the embodiment of the coordinated control method in the present invention on the steam pipe network and gas pipe network dispatching center of a metallurgical gas-fired boiler plant generally includes a data acquisition module, a gas pipe network safety margin judgment, and a load regulation margin calculation Module, gas boiler control module, and the gas main control valve of each gas boiler.

[0020] The data acquisition module, through a standard communication protocol and an effective physical connection, obtains real-time data on site, mainly including the pressure of the gas pipe network, the pressure of the steam pipe network, the number of gas-fired boilers operating in the pipe network, and the production scale of each gas-fired boiler , The opening and adjustment limit of the gas main pipe control valve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com