SMD type linear ultrasonic motor based on 3D printed resin stator

A linear ultrasonic motor, 3D printing technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the limitation of stator size, small output torque of stator, and processing error Large and other problems, to achieve the effect of not being disturbed by magnetic field and electric field, high 3D printing precision, not easy to oxidize and corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

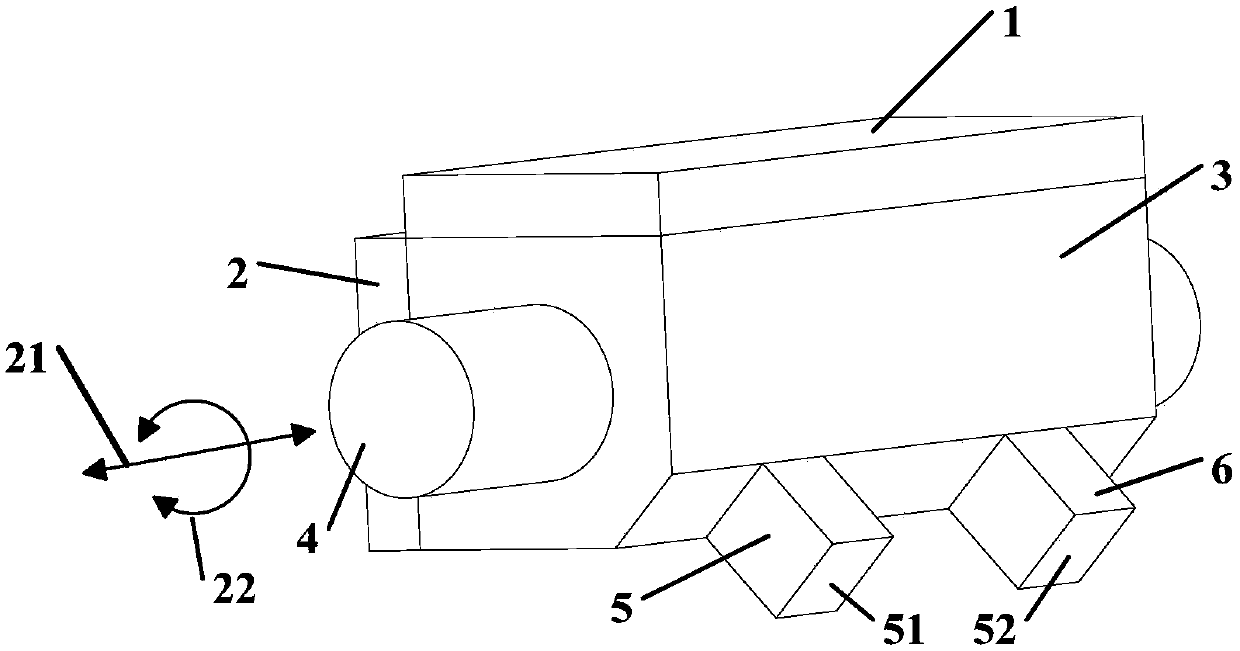

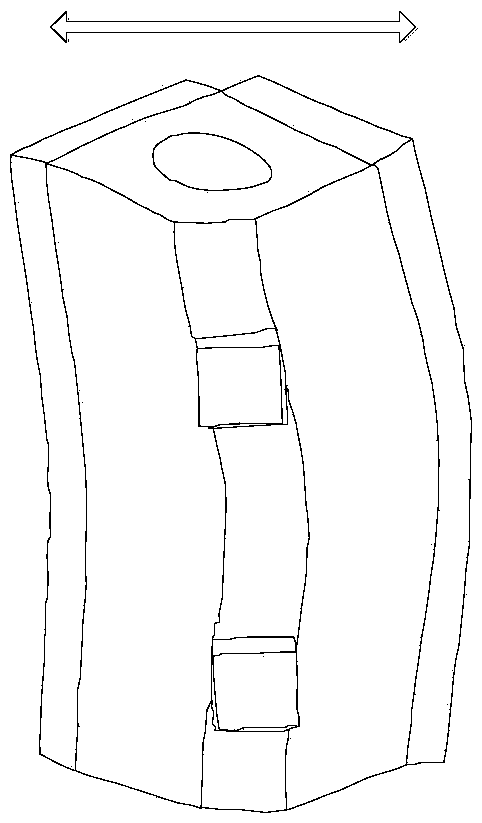

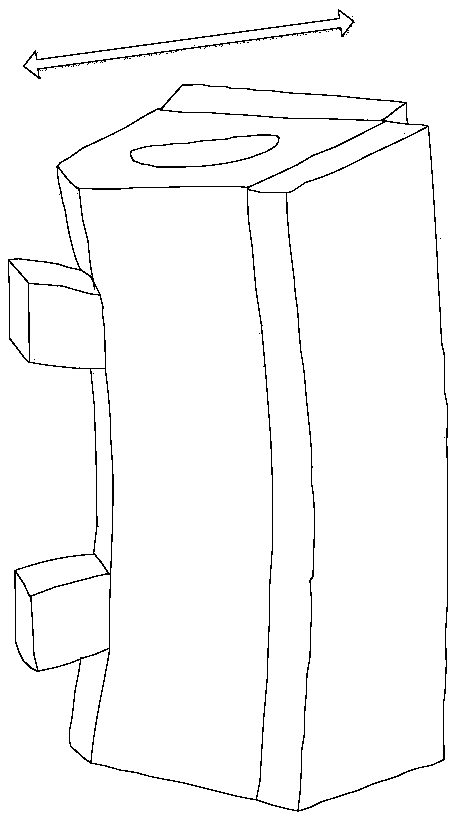

[0018] Such as figure 1 , Figure 4 and Figure 6 As shown, a patch type linear ultrasonic motor based on a 3D printed resin stator, including: a stator, a mover, two piezoelectric ceramic sheets and two fixed bosses; the stator is formed by cutting off a corner on the basis of a cuboid The pentagonal prism has two symmetrically distributed bosses on the oblique side, the stator drives the mover to rotate, and the two piezoelectric ceramic sheets are glued to the stator.

[0019] The stator 3 is a tough photosensitive resin made of non-metallic material, which is processed by 3D printing. The shape of the stator is a pentagonal prism formed by cutting off a corner on the basis of a cuboid. There are two symmetrically distributed bosses 5 and 6 on the oblique side. When the motor is installed, the end faces 51 and 52 of the bosses are bonded to the external structure with super glue , used to fix the stator. The center of the stator is a through hole, and the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com