Multilayer phase-change film for ultrahigh density probe storage and preparation method thereof

A probe storage, ultra-high density technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of reducing storage density, affecting conductivity, needle tip and film wear, etc., to achieve excellent conductivity and Effects of heat dissipation, improved surface quality, and reduced temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

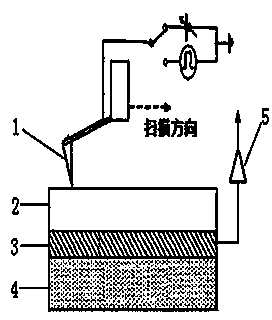

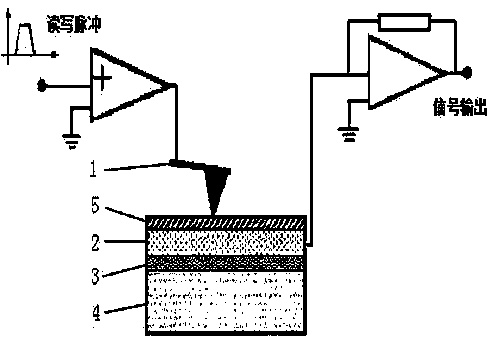

[0018] Attached below figure 2 The multilayer phase-change thin film of the present invention and its preparation method are further described in detail with typical embodiments, but the present invention is by no means limited to the described embodiments, for example, the diamond-like carbon (DLC) film of the protective layer 5 can also be selected Elements such as phosphorus (P) are doped to improve the conductivity of the DLC film.

[0019] like figure 2 As shown, the multi-layer nano film of the present invention is prepared on the substrate 4, which is a sandwich structure. The top layer of the multi-layer nano film is the protective layer 5, the bottom layer is the electrode layer 3, and the middle layer is the phase change layer 2. The electrode layer 3 has a thickness of 10-15nm, is a copper-tungsten alloy film, and the weight ratio of copper to tungsten is 15:85. The phase change layer 2 is a tellurium-based alloy film with a thickness of 25-45nm, and the phase c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com