Composite fructose powder composition capable of improving spray drying wall adhesion and spray drying method

A drying method and composition technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of low yield of spray-dried powder, powder sticking to the wall, etc., so as to improve the problem of powder sticking to the wall and increase the flow. Sexual, significant economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

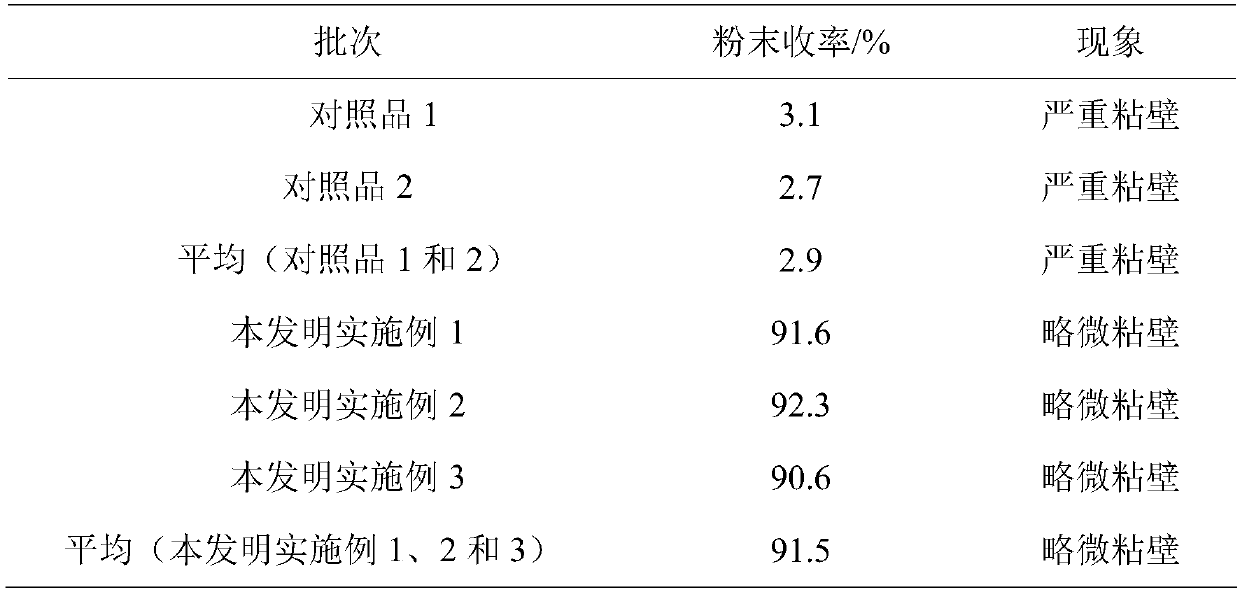

Examples

Embodiment 1

[0020] (1) Configure compound fructose solution:

[0021] Take 100 parts of F55 liquid fructose, add 200 parts of water, stir well, add 20 parts of maltodextrin, after continuing to stir well, add 14 parts of sucrose, stir evenly, and make a suspension for later use;

[0022] (2) spray drying:

[0023] Add 3 parts of microcrystalline cellulose, 3 parts of calcium chloride, and 5 parts of silicon dioxide to the suspension prepared in step (1), stir well and then spray dry, the air inlet temperature is 120°C, and the atomization pressure is 0.75 bar , Inlet volume flow rate 4ml / min, gas flow rate 40m 3 / h to make compound fructose powder.

Embodiment 2

[0025] (1) Configure compound fructose solution:

[0026] Take 100 parts of F55 liquid fructose, add 200 parts of water, stir well, add 20 parts of maltodextrin, after continuing to stir well, add 14 parts of sucrose, stir evenly, and make a suspension for later use;

[0027] (2) spray drying:

[0028] Add 6.5 parts of microcrystalline cellulose, 5.5 parts of calcium chloride, and 10 parts of silicon dioxide to the suspension prepared in step (1), stir evenly and then spray dry, the air inlet temperature is 120°C, and the atomization pressure is 0.75 bar , Inlet volume flow rate 4ml / min, gas flow rate 40m 3 / h to make compound fructose powder.

Embodiment 3

[0030] (1) Configure compound fructose solution:

[0031] Take 100 parts of F55 liquid fructose, add 200 parts of water, stir well, add 20 parts of maltodextrin, after continuing to stir well, add 14 parts of sucrose, stir evenly, and make a suspension for later use;

[0032] (2) spray drying:

[0033] Add 10 parts of microcrystalline cellulose, 8 parts of calcium chloride, and 15 parts of silicon dioxide to the suspension prepared in step (1), stir evenly, and then spray dry. The air inlet temperature is 120°C and the atomization pressure is 0.75 bar , Inlet volume flow rate 4ml / min, gas flow rate 40m 3 / h to make compound fructose powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com