Recycled material crushing system

A technology of crushing system and recycled materials, which is applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of no systematic production, low efficiency of shredding process, time-consuming and labor-intensive, etc., so as to save manpower and material resources, improve Labor efficiency, the effect of reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

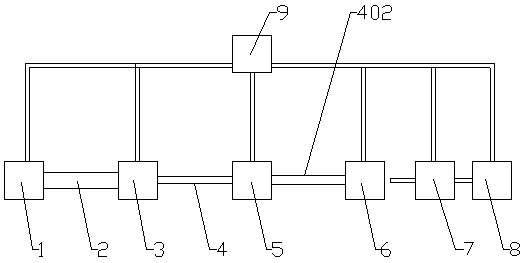

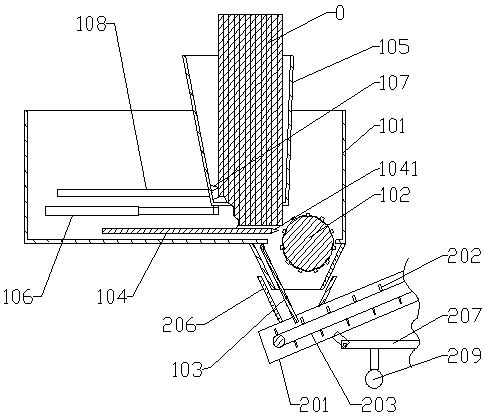

[0046] Accompanying drawing is the specific embodiment of the present invention. Such as Figures 1 to 10 As shown, the whole system is controlled by PLC control system, and it also includes shredder 1, conveying device 2, crusher 3, first screw conveyor 4, mixer 5, The second screw conveyor 402, pulverizer 6, cyclone separator 7 and lower silo 8, shredder 1, crusher 3, mixer 5, pulverizer 6, cyclone separator 7 and lower hopper 8 are respectively connected with Dust removal device 9 is connected, wherein,

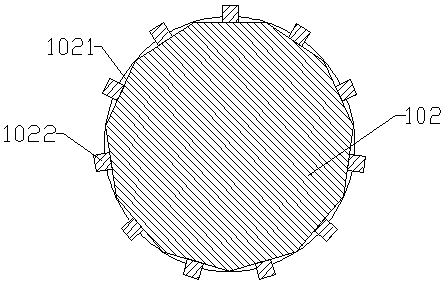

[0047] The shredder 1 comprises a shredding box 101, the front side of the lower end of the shredding box 101 is provided with a discharge port, the discharge port mouth is downward, and a shredding knife roller 102 is installed in the discharge opening, and the two ends of the shredding knife roller 102 are shafted. Rotatingly installed on the inner wall of the shredding box 101, the shredding knife roller 102 is driven by a motor to rotate, the axis of the shredding kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com