Two-way easy-to-tear film

An easy-to-tear, weight-percent technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of spilled contents, low efficiency, uneven tear edges, etc., to improve production. Efficiency, good customer experience, wide heat sealing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The two-way easy-to-tear film described in Example 1 has a three-layer structure, which is an outer layer, a middle layer and an inner layer. The layer is 30%; each layer consists of the following components:

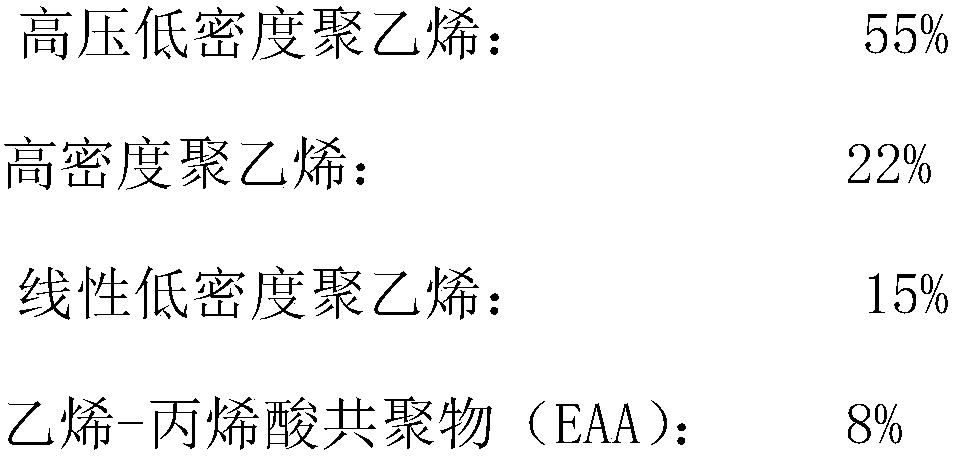

[0024] Each component and weight percent of outer layer:

[0025]

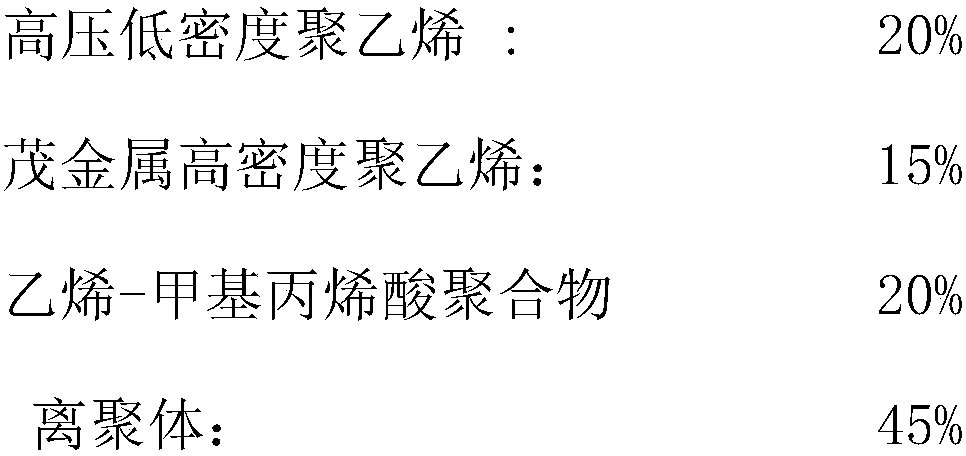

[0026] Each component and weight percent of middle layer:

[0027]

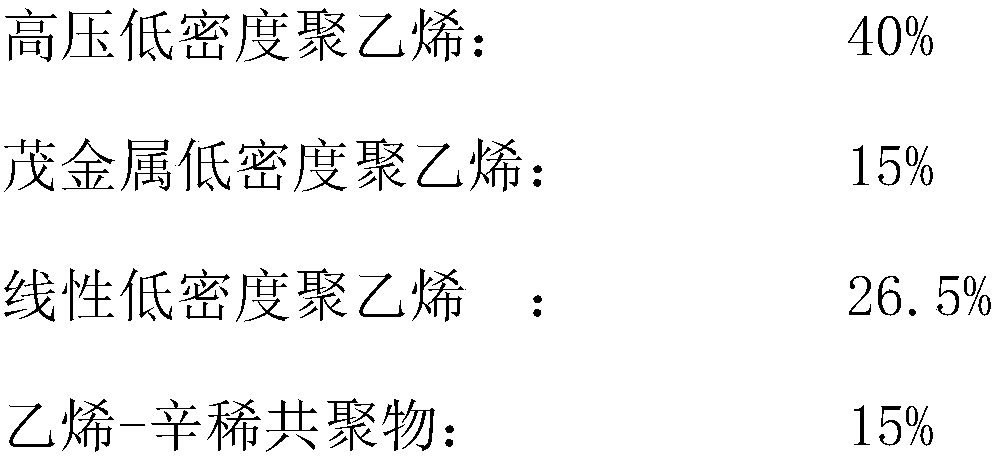

[0028] Each component and weight percent of inner layer:

[0029]

[0030]

[0031] The method for preparing the two-way easy-tear film is as follows: after mixing the raw materials of the outer layer, middle layer and inner layer according to the above weight percentages through an automatic mixing system, the raw materials of each layer are respectively added to the outer layer extruder, and the middle layer is extruded. machine and the inner layer extruder are melted and plasticized, and then sent to the die for co-extrusion to form a film bubble. After automatic wind ring cooling and corona treatment, the two-w...

Embodiment 2

[0033] The present embodiment 2 is changed on the basis of embodiment 1, and the weight percentage between the outer layer, the middle layer and the inner layer is different, and the components of each layer are the same, as follows:

[0034] The percentages by weight of the materials of the outer layer, the middle layer and the inner layer of the present embodiment 2 are respectively: 25% for the outer layer, 50% for the middle layer, and 25% for the inner layer.

Embodiment 3

[0036] A two-way easy-tear film described in Example 3 has a three-layer structure, which is an outer layer, a middle layer, and an inner layer. The layer is 25%; each layer consists of the following components:

[0037] Each component and weight percent of outer layer:

[0038]

[0039]

[0040] Each component and weight percent of middle layer:

[0041]

[0042] Each component and weight percent of inner layer:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com