Titanium calcium aluminate castable for ladle or foundry ladle and preparation method thereof

A technology of calcium titanoaluminate and calcium titanoaluminate is applied in the field of calcium titanoaluminate castables and preparation fields for ladle or iron ladle, and can solve the problems of shortening construction time, low strength of castables, reduced overall strength and the like, Achieve the effect of reducing production costs, good volume stability, and reducing the number of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific examples and comparative examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

[0031] By controlling the particle size and addition of calcium aluminate titanate, high alumina bauxite clinker, calcium aluminate cement, alumina micropowder and silica micropowder, as well as the addition of polypropylene fiber and water reducing agent during preparation, and the homogenization time , water addition, curing time and baking time and other process parameters, a calcium aluminate titanate castable with good volume stability, high medium and high temperature strength, long service life, economical and environmental protection was prepared.

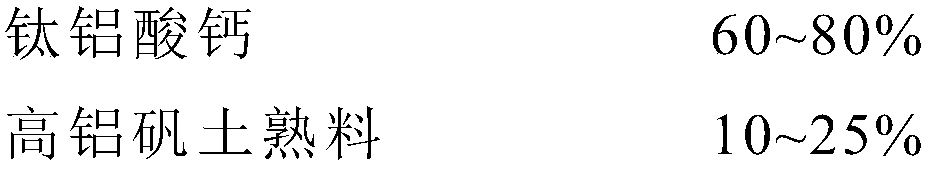

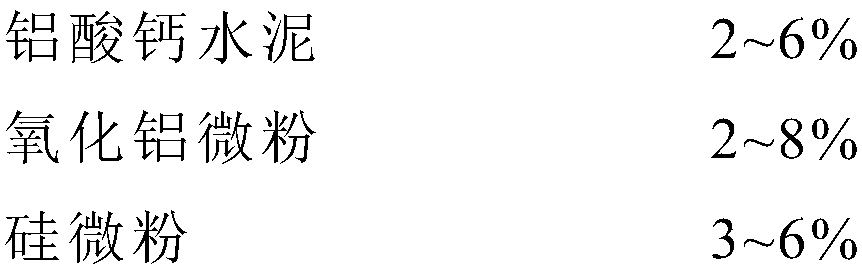

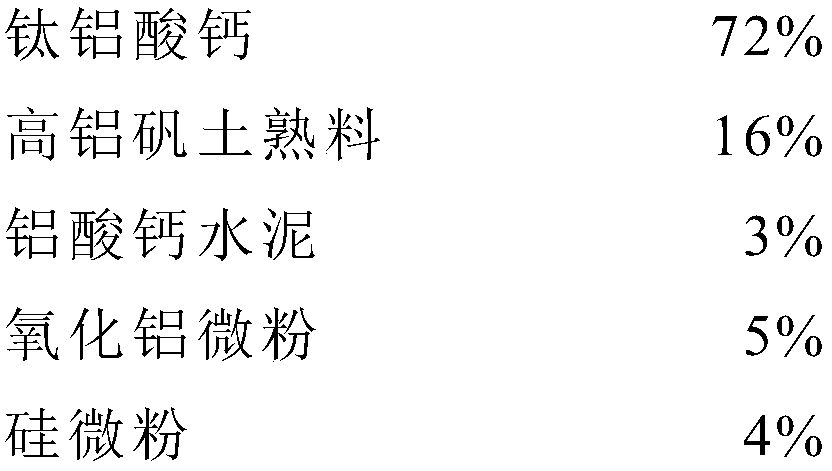

[0032] Table 1 is the raw material addition list of each embodiment of the present invention and comparative example;

[0033] Table 2 is the main process parameter of each embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com