Synthesis method of (E)-4-aryl-3-butenonitrile compound

A synthesis method and compound technology are applied in the field of chemical organic synthesis to achieve the effects of simple reaction steps, wide substrate range and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

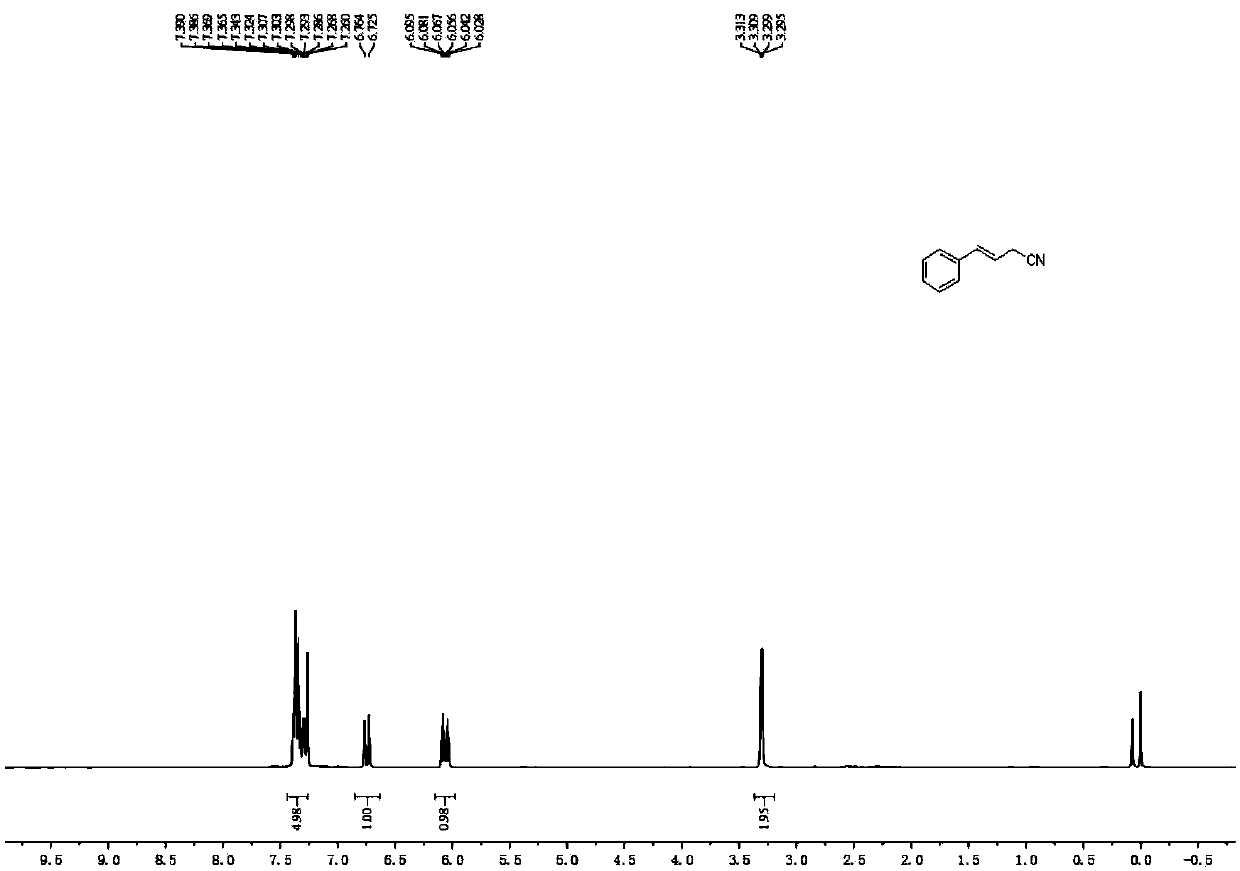

[0021] First, put a stirring bar in a 35mL sealed tube, add 35μL styrene (0.3mmol), 1.0ml acetonitrile, 38μL bromoacetonitrile (0.60mmol), and add 5.4mg Phen (0.03 mmol), 5.7mgCuI (0.03mmol) and 91μL DBU (0.60mmol), seal the nozzle tightly with a cock, heat to 110°C, and stir for 1.5 hours. After the reaction, the system is cooled to room temperature, and 2ml of distilled water is added to the reaction system. Extracted with ethyl acetate, combined the organic phases, and distilled off the solvent of the organic phase under reduced pressure, and separated by silica gel column chromatography to obtain 37.8 mg of colorless liquid product 3a, with a yield of 88%. The reaction is shown in the following formula:

[0022]

[0023] Spectral analysis data:

[0024] 1 H NMR (400MHz; CDCl 3 ):δ=3.30(dd,J 1 =1.6Hz,J 2 =5.6Hz,2H),6.06(dt,J 1 =15.6,J 2 =5.6Hz, 1H), 6.75(d, J=15.6Hz, 1H), 7.27-7.39(m, 5H); 13 C NMR (100MHz, CDCl 3 ): δ=20.8, 116.7, 117.3, 126.5, 128.3, 128.7, 13...

Embodiment 2

[0026] First, put a stirring bar in a 35mL sealed tube, add 37μL 4-fluorostyrene (0.3mmol), 1.0ml acetonitrile, 38μL bromoacetonitrile (0.60mmol), and add 5.4mg Phen (0.03mmol), 5.7mg CuI (0.03mmol) and 91μL DBU (0.60mmol), seal the mouth of the tube tightly with a cock, heat to 110°C, stir for 1.5 hours, after the reaction is over, cool the system to room temperature, and pour into the reaction system Add 2ml of distilled water, extract with ethyl acetate, combine the organic phases, distill off the solvent of the organic phase under reduced pressure, and separate by silica gel column chromatography to obtain 44.0 mg of colorless liquid product 3b, with a yield of 91%. The reaction is shown in the following formula:

[0027]

[0028] Spectral analysis data:

[0029] 1 H NMR (400MHz; CDCl 3 ):δ=3.29(dd,J 1 =1.2Hz,J 2 =5.6Hz,2H),5.98(dt,J 1 =15.6,J 2 =5.6Hz, 1H), 6.71(d, J=15.6Hz, 1H), 7.03(t, J=8.8Hz, 2H), 7.34(dd, J 1 =5.6,J 2 =8.4Hz,2H); 13 C NMR (100MHz, CDCl ...

Embodiment 3

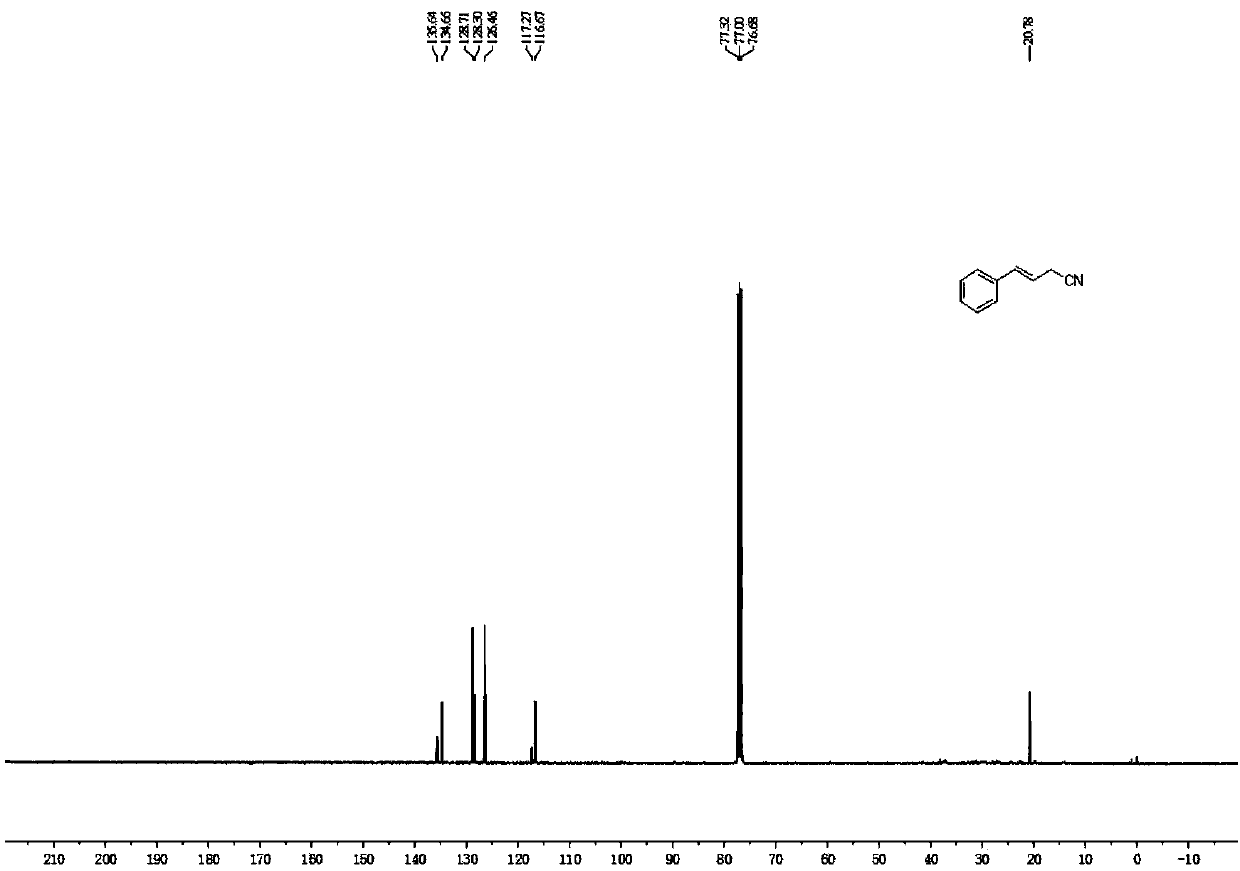

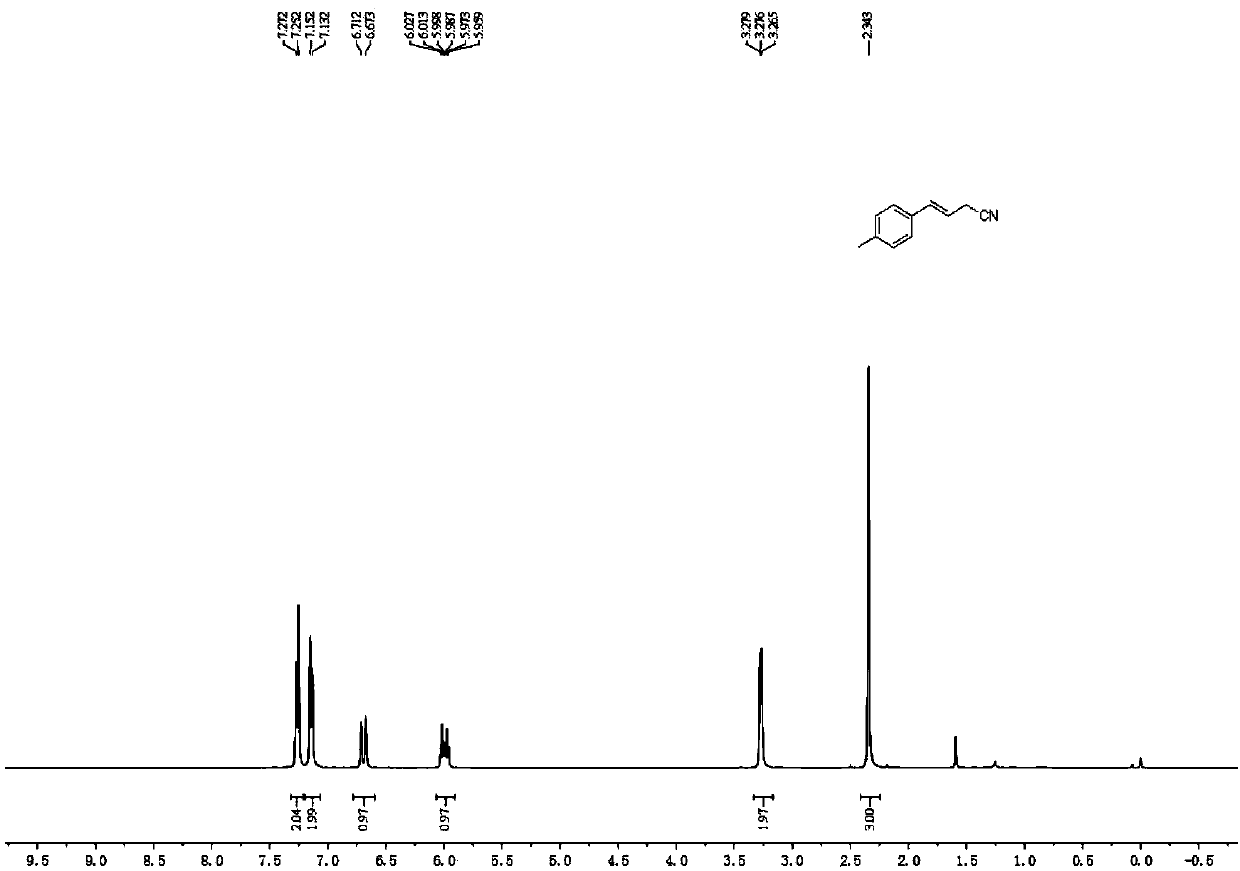

[0031]First, put a stirring bar in a 35mL sealed tube, add 40μL 4-methylstyrene (0.3mmol), 1.0ml acetonitrile, 38μL bromoacetonitrile (0.60mmol), and add 5.4 mg Phen (0.03mmol), 5.7mg CuI (0.03mmol) and 91μL DBU (0.60mmol), seal the nozzle tightly with a cock, heat to 110°C, and stir for 1.5 hours. 2ml of distilled water was added to the mixture, extracted with ethyl acetate, the organic phases were combined, the solvent of the organic phase was distilled off under reduced pressure, and 33.5mg of colorless liquid product 3c was obtained by silica gel column chromatography, with a yield of 71%. The reaction is shown in the following formula:

[0032]

[0033] Spectral analysis data:

[0034] 1 H NMR (400MHz; CDCl 3 ):δ=2.43(s,3H),3.27-3.28(m,2H),5.99(dt,J 1 =16.0,J 2 =5.6Hz,1H),6.69(d,J=15.6,1H),7.14(d,J=8.0,2H),7.26(d,J=8.0,2H); 13 C NMR (100MHz, CDCl 3 ): δ=20.7, 21.2, 115.6, 117.4, 126.3, 129.4, 132.8, 134.5, 138.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com