Preparation method of low-melting point elastic polyester

A technology of elastic polyester and low melting point, applied in the direction of single-component copolyester rayon, etc., can solve the limitations of product application fields, the physical properties of low melting point polyester products are general, and the physical properties of low melting point polyamide cannot be achieved and other problems, to achieve the effects of low cost, increased reaction speed of esterification and polymerization, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

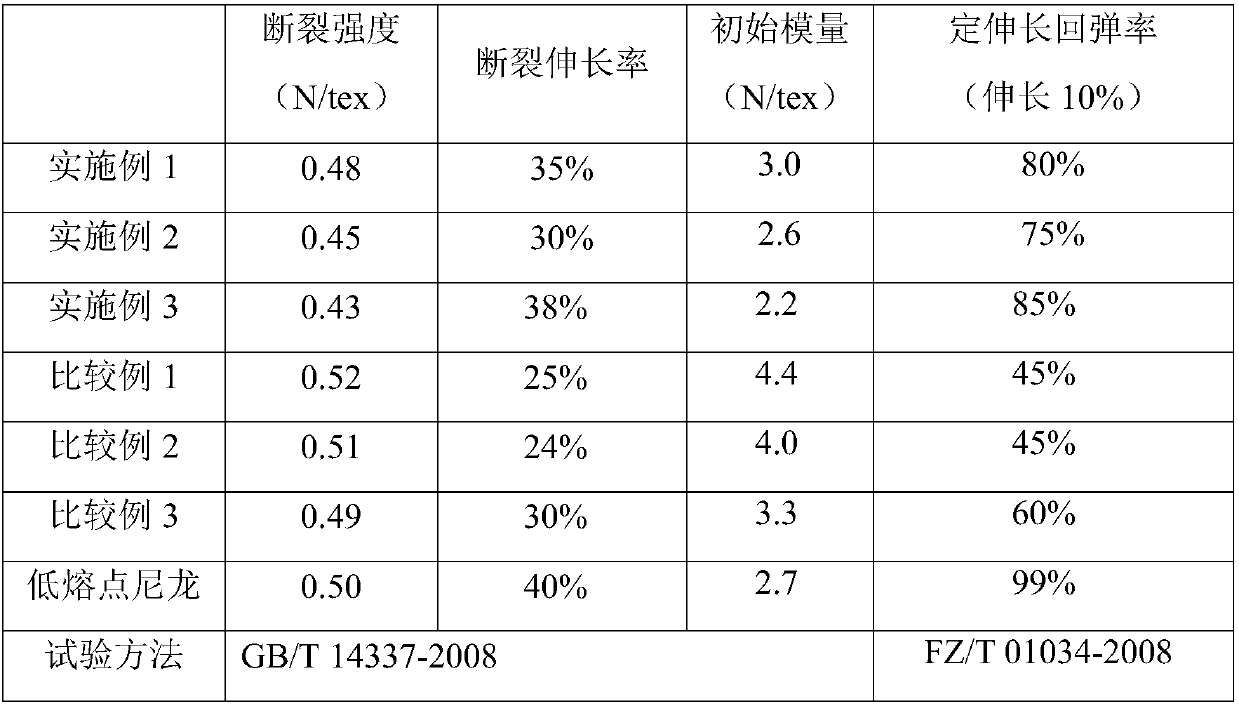

Examples

Embodiment 1~3

[0031] 1) With terephthalic acid, isophthalic acid, ethylene glycol, and a certain amount of aliphatic (cyclic) dibasic acids with more than three carbon chains, and aliphatic (cyclic) dibasic alcohols with more than three carbon chains, certain A certain amount of polyether polyol is the reaction raw material, and the esterification reaction is carried out at 200-250°C under normal pressure. The rate is not less than 92%, and the generated water is removed during the reaction process;

[0032] 2) Prepolymerization: After the reaction is finished, the system is slowly evacuated to a vacuum degree of 200-300Pa, the temperature is 230-260°C, and the duration is 1-2 hours;

[0033]3) Polycondensation: Then draw a high vacuum, the vacuum degree is ≤200Pa, the temperature is 240-270°C, and the duration is 2-3 hours to obtain a low melting point elastic copolyester.

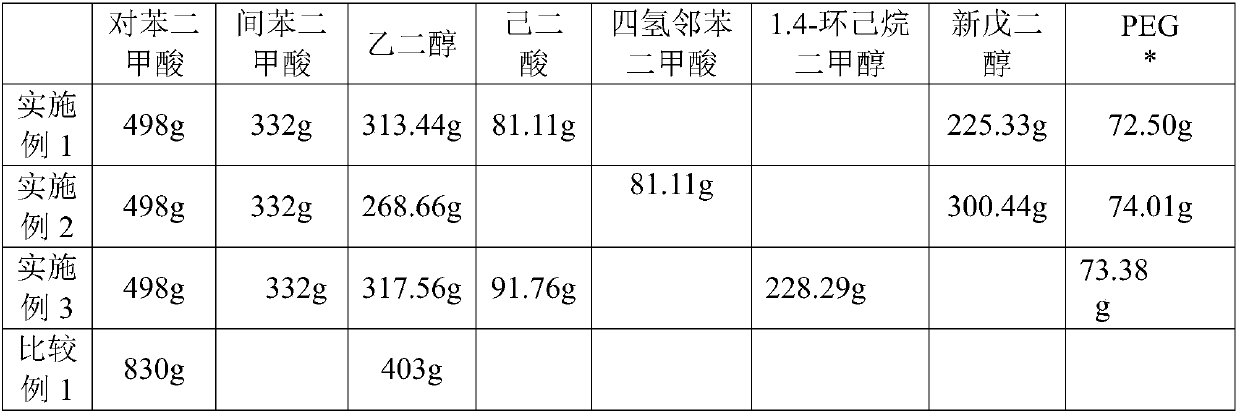

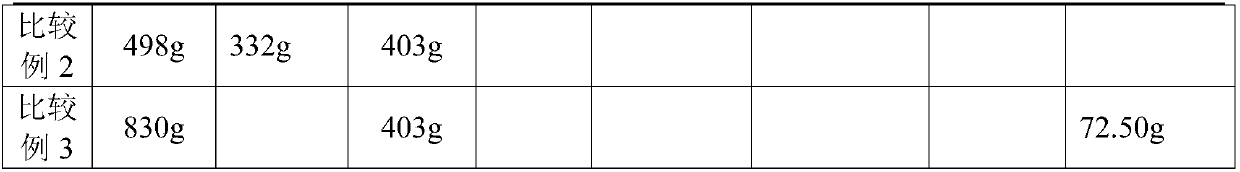

[0034] The reaction raw material proportioning of embodiment 1~3 is shown in Table 1. The types of raw materials i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com