Making method of high strength spray quick-setting rubber waterproof paint

A quick-setting rubber and waterproof coating technology, applied in the direction of asphalt coatings, coatings, etc., can solve the problems of low strength and elastic recovery rate, tensile damage, low construction efficiency, etc., and achieve high strength and elastic recovery rate, not easy to pull The effects of stretching damage and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A high-strength spraying quick-setting rubber waterproof coating, including A component and B component, A component is composed of the following materials in terms of mass percentage: emulsified asphalt accounts for 60%; polymer rubber emulsion accounts for 30%; The proportion of powder filler is 5%; the proportion of dispersant is 0.5%; the proportion of flame retardant is 0.5%; the proportion of tackifier is 1%; B component is the curing agent.

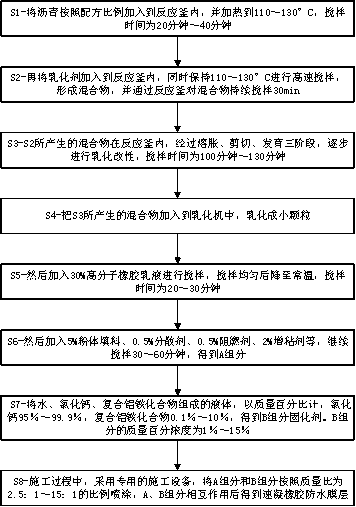

[0025] A preparation method, comprising the steps of:

[0026] S1-Add 60% asphalt into the reaction kettle according to the formula ratio, and heat to 110°C, and the stirring time is 20 minutes;

[0027] S2- Then add the emulsifier into the reaction kettle, while maintaining 110°C for high-speed stirring to form a mixture, and continue stirring the mixture through the reaction kettle for 30 minutes;

[0028] The mixture produced by S3-S2 is emulsified and modified step by step in the reactor through three stages of swelling...

Embodiment 2

[0035] A high-strength spray quick-setting rubber waterproof coating, including A component and B component, A component is composed of the following materials in terms of mass percentage: emulsified asphalt accounts for 50%; polymer rubber emulsion accounts for 35%; Powder filler accounted for 10%; dispersant accounted for 0.8%; flame retardant accounted for 0.8%; tackifier 2%; B component is curing agent.

[0036] A preparation method, comprising the steps of:

[0037] S1-Add 50% asphalt into the reaction kettle according to the formula ratio, and heat to 120°C, and the stirring time is 30 minutes;

[0038] S2-add the emulsifier into the reaction kettle again, while maintaining 120°C for high-speed stirring to form a mixture, and continue stirring the mixture through the reaction kettle for 30 minutes;

[0039] The mixture produced by S3-S2 is emulsified and modified step by step in the reactor through three stages of swelling, shearing and development, and the stirring tim...

Embodiment 3

[0046] A high-strength spray quick-setting rubber waterproof coating, including A component and B component, A component is composed of the following materials by mass percentage: emulsified asphalt accounts for 55%; polymer rubber emulsion accounts for 32%; The proportion of powder filler is 12%; the proportion of dispersant is 1%; the proportion of flame retardant is 1%; the proportion of tackifier is 5%; component B is the curing agent.

[0047] A preparation method, comprising the steps of:

[0048] S1-Add 55% asphalt into the reaction kettle according to the formula ratio, and heat to 120°C, and the stirring time is 30 minutes;

[0049] S2-add the emulsifier into the reaction kettle again, while maintaining 120°C for high-speed stirring to form a mixture, and continue stirring the mixture through the reaction kettle for 30 minutes;

[0050] The mixture produced by S3-S2 is emulsified and modified step by step in the reactor through three stages of swelling, shearing and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com