Cyaniding carbon-in-pulp technology thick reclaimed water activated carbon adsorption device

An activated carbon adsorption and dense technology is applied in the field of dense return water activated carbon adsorption device of cyanidation carbon slurry process, which can solve the problem of high operating cost and achieve the effects of improving recovery rate, reducing accumulation and avoiding inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

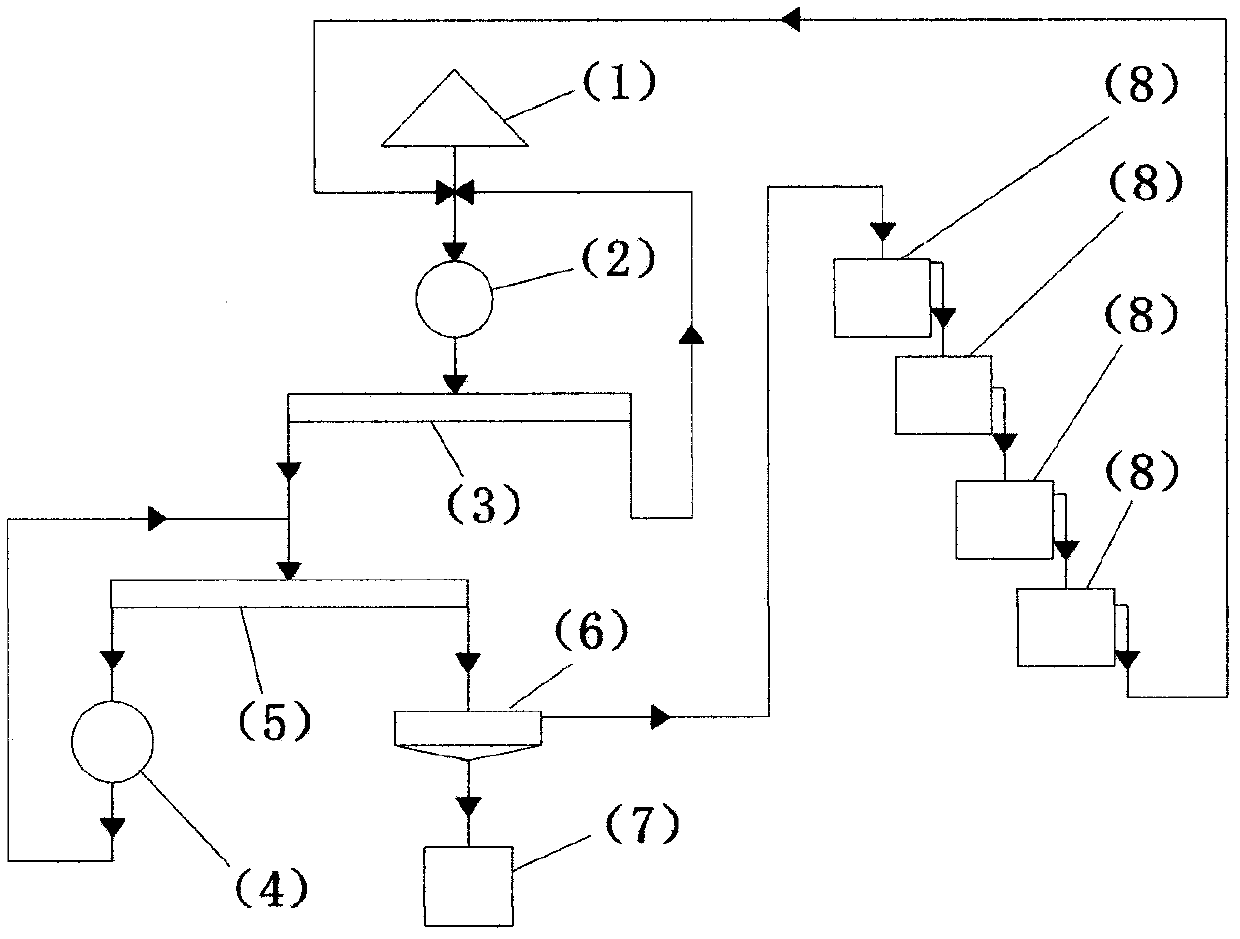

[0009] figure 1 It is a kind of cyanide carbon slurry process thick backwater activated carbon adsorption device embodiment of the present invention, is the full mud cyanide carbon slurry method recovery gold flow process of Inner Mongolia Baotou Xinda Gold Mining Co., Ltd. (hereinafter referred to as Xinda Company), wherein adopts A dense backwater activated carbon adsorption device for the cyanided carbon slurry process of the present invention has been developed.

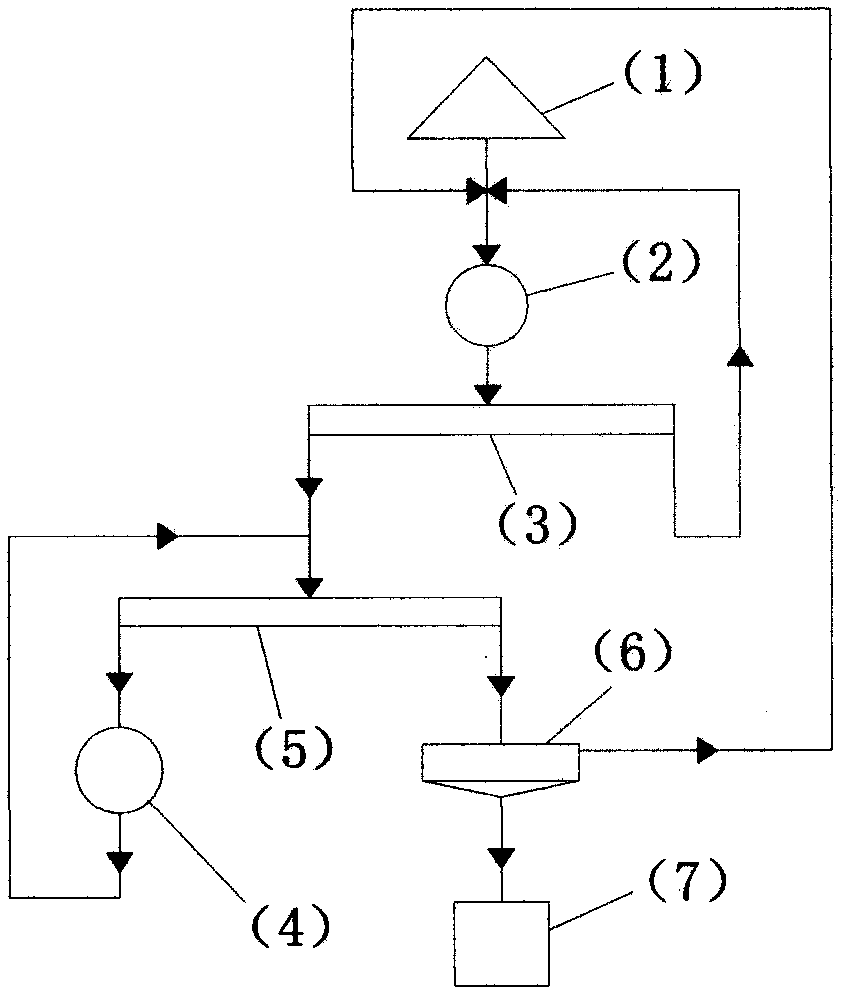

[0010] Xinda Company's original process flow of all mud cyanide carbon slurry method is as follows: figure 2 shown. The ore is fed into the first overflow ball mill (2) and the first cyclone group (3) from the fine ore bin (1) for rough grinding, and then enters the second overflow ball mill (4) The closed-circuit grinding process composed of the second stage cyclone group (5) is used for fine grinding, the processing capacity is 3000t / d, and the final grinding product fineness is -200 mesh 90%. Grinding prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com