Preparation method of smart fabric based on silk artificial muscles

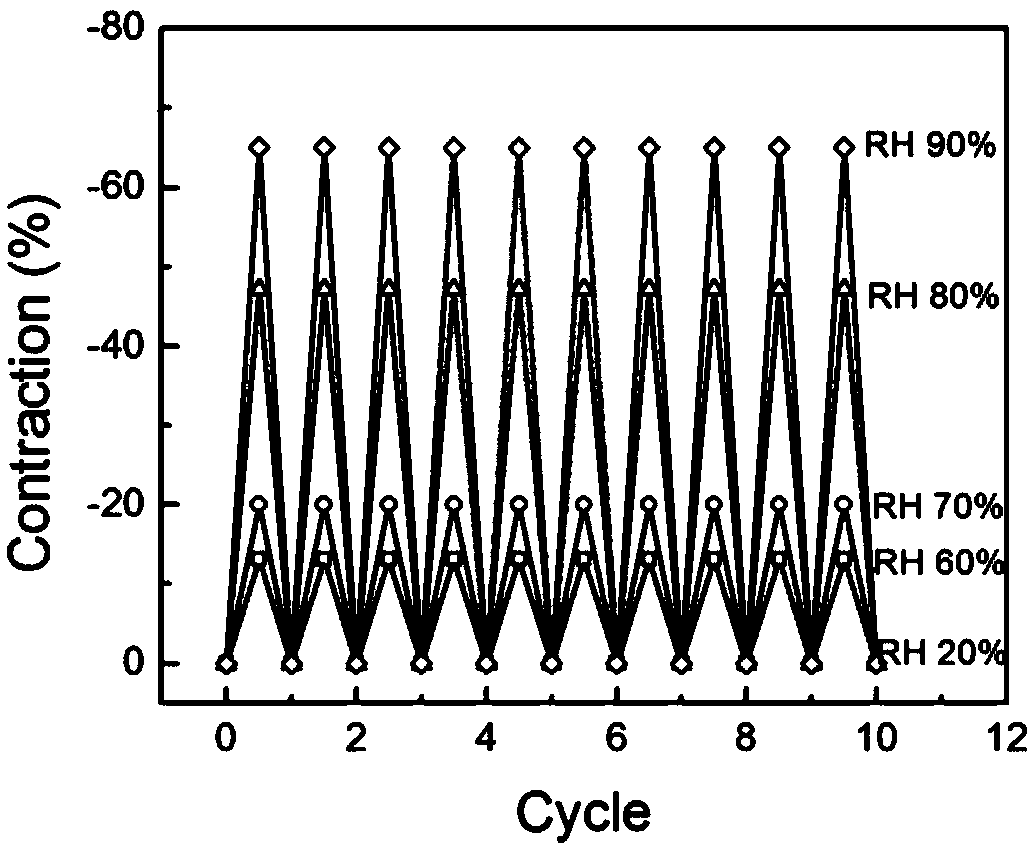

A technology for artificial muscles and silk, which can be used in fabrics, fabric surface trimming, heating/cooling fabrics, etc., which can solve the problems of high cost and complicated material preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

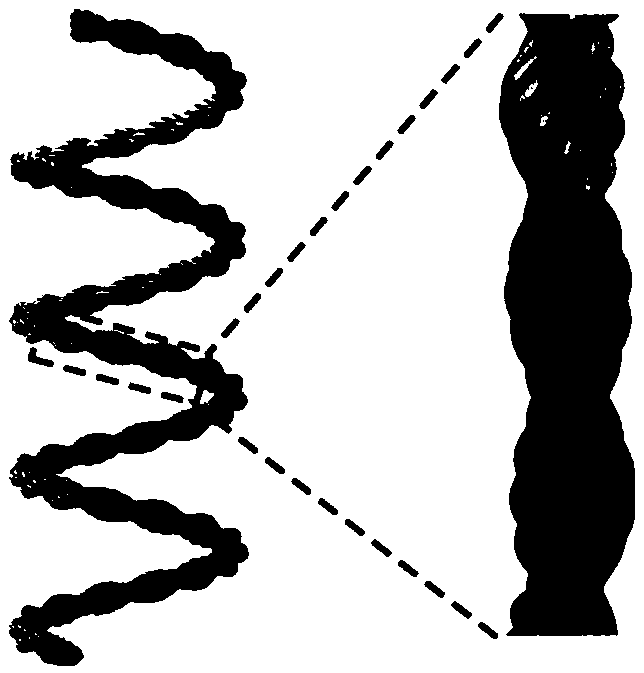

[0029] The preparation method of described silk artificial muscle comprises the following steps:

[0030] Step 1: Soak commercially purchased cocoons in 0.1mol / L sodium hydroxide solution for degumming, and the soaking time is 36h;

[0031] Step 2: washing the degummed silk obtained in the step 1 with deionized water, and drying at room temperature;

[0032] Step 3: Preparation of Silk Yarn

[0033] Spinning the 5 degummed silks in the step 2, the twist direction is "Z" twist, the twist is 6000 turns / m, and the yarn diameter is 50 μm;

[0034] Step 4: hang a 3g weight from the middle of the yarn in step 3, and fold it in half to obtain a self-balancing half-folded yarn;

[0035] Step 5: winding the double-folded yarn obtained in step 4 around a 0.5mm mandrel, the coil spacing is 1.5mm, and the winding direction is the same as the spinning twist direction;

[0036] Step 6: Put the artificial muscle obtained in step 5 together with the mandrel into a drying oven for heat sett...

Embodiment 2

[0040] The preparation method of described silk artificial muscle comprises the following steps:

[0041] Step 1: Soak commercially purchased cocoons in 0.5mol / L sodium hydroxide solution for degumming, and the soaking time is 12h;

[0042] Step 2: washing the degummed silk obtained in the step 1 with deionized water, and drying at room temperature;

[0043] Step 3: Preparation of Silk Yarn

[0044] Spinning the 5 degummed silks in the step 2, the twist direction is "Z" twist, the twist is 6000 turns / m, and the yarn diameter is 50 μm;

[0045] Step 4: hang a 3g weight from the middle of the yarn in step 3, and fold it in half to obtain a self-balancing half-folded yarn;

[0046] Step 5: winding the double-folded yarn obtained in the step 4 around a 3mm mandrel, the coil spacing is 6mm, and the winding direction is the same as the spinning twist direction;

[0047] Step 6: Put the artificial muscle obtained in step 5 together with the mandrel into a drying oven for heat sett...

Embodiment 3

[0051] The preparation method of described silk intelligent fabric, comprises the following steps:

[0052] Step 1: Soak commercially purchased cocoons in 0.2mol / L sodium hydroxide solution for degumming, and the soaking time is 30h;

[0053] Step 2: washing the degummed silk obtained in the step 1 with deionized water, and drying at room temperature;

[0054] Step 3: Preparation of Silk Yarn

[0055] Spinning the 20 degummed silks in the step 2, the twist direction is "Z" twist, the twist is 2500 turns / m, and the yarn diameter is 200 μm;

[0056] Step 4: hang a 10g weight from the middle of the yarn in step 3, and fold it in half to obtain a self-balancing half-folded yarn;

[0057] Step 5: winding the double-folded yarn obtained in step 4 around a 1mm mandrel, the coil spacing is 2mm, and the winding direction is the same as the spinning twist direction;

[0058]Step 6: Put the artificial muscle obtained in step 5 together with the mandrel into a drying oven for heat sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com