A molten salt heat storage system and heat exchange method for solar thermal power plants

A technology of heat storage system and photothermal power station, which is applied in the direction of steam generation method using solar energy, solar heating system, solar heat storage, etc., and can solve the problems of affecting system operation efficiency, low molten salt outlet temperature, freezing blockage of preheater, etc. problems, to achieve the effect of increasing economic benefits, increasing molten salt temperature, and increasing margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

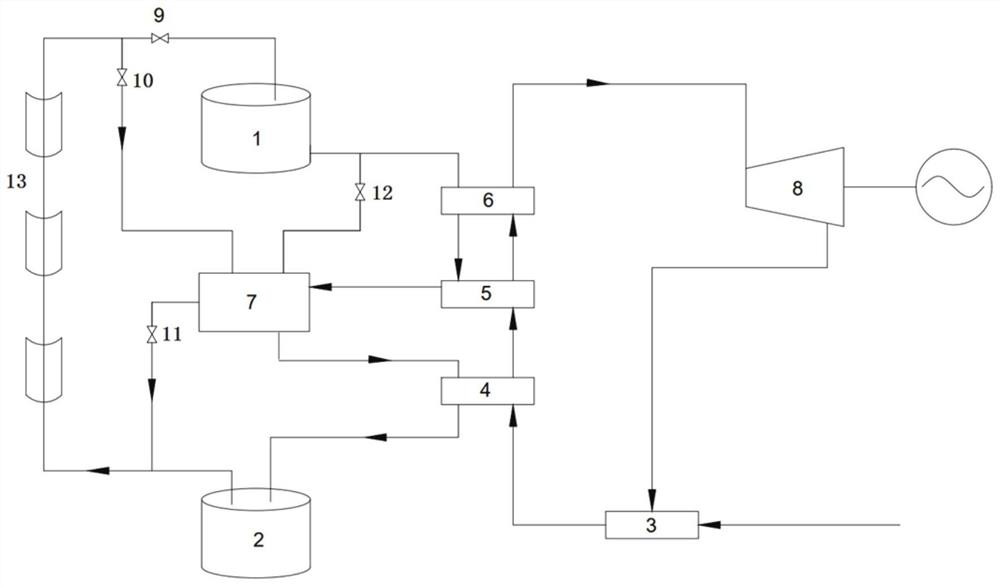

[0046] The low-pressure heater 3, preheater 4, evaporator 5, superheater 6, and the pipelines, valves, and instruments between each equipment constitute the main steam-water circuit, and the hydraulic medium is heated by molten salt through the steam-water pipeline in turn to become superheated steam Enter steam turbine 8 to do work and generate electricity.

[0047] The high-temperature molten salt storage tank 1, the low-temperature molten salt storage tank 2, the molten salt pump, the mixer 7, and the pipelines, valves, and instruments between each equipment constitute the main molten salt circuit. During daytime operation, open the first valve 9 and 12, close the second valve 10 and the third valve 11, and the molten salt in the high-temperature molten salt storage tank is transported to the heater and steam by the submerged molten salt pump on the top of the tank under pressure. After the generator, the high-temperature molten salt in the high-temperature molten salt stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com