Integrated device and operation method for efficiency enhancement and antifreeze of photothermal assisted indirect air cooling tower

An integrated device and air-cooling tower technology, which is applied in the field of photo-thermal assisted indirect air-cooling tower efficiency enhancement and anti-freezing integrated devices, can solve the problems of excess cooling capacity, increased unit back pressure, poor anti-freezing ability, etc., to improve cooling capacity, Reduce the running back pressure and improve the effect of antifreeze ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

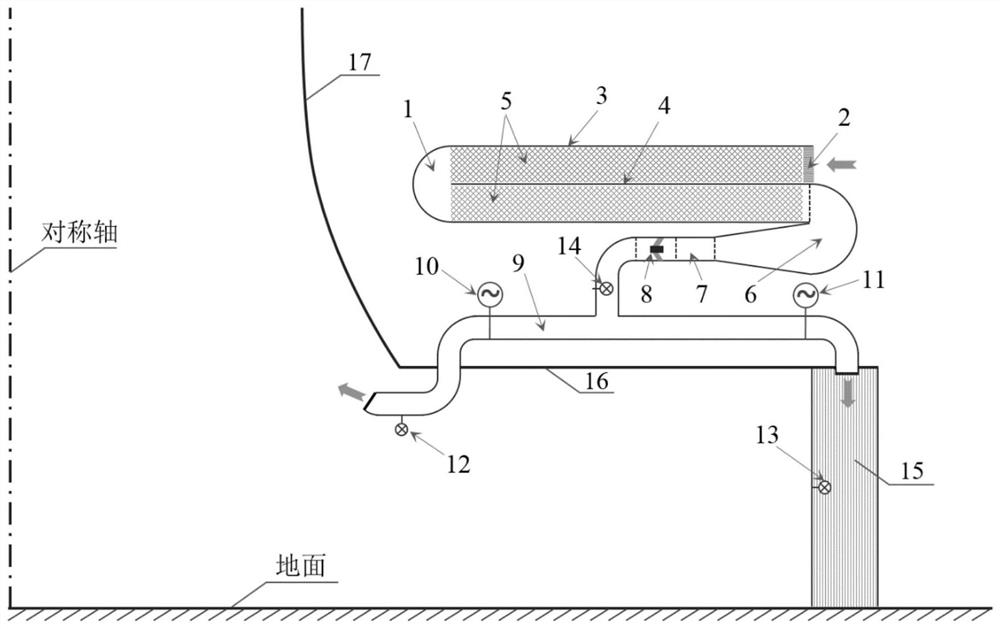

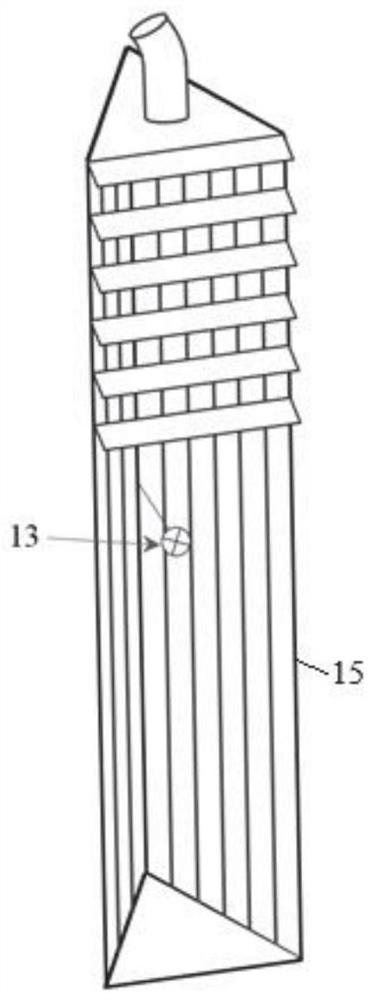

[0034] like figure 1 As shown, the photothermal assisted indirect air-cooling tower efficiency enhancement and antifreeze integrated device of this embodiment is arranged on the ring-shaped sealing platform 16 where the main body of the indirect air-cooling tower 17 is connected to the air-cooling radiator 15, and can be supported by necessary structural members.

[0035] The integrated device includes a multi-flow transparent air duct 1, which is equipped with a heat storage medium 5, the outlet of the transparent air duct 1 is connected to the inlet of the tapered pipe 6, and the outlet of the tapered pipe 6 is connected to the inlet of the air supply pipe 9 through the connecting pipe 7 The air supply duct 9 includes two air outlet branches, the corresponding first air outlet is located inside the indirect air cooling tower 17, close to the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com