Method for recovery of ethane from carbon dioxide-containing natural gas

A carbon dioxide and recovery method technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of increasing the liquid phase volume of the cryogenic separator, decreasing the recovery rate of ethane, increasing the energy consumption of the system, etc., reaching B Improve the recovery rate of alkane, reduce the energy consumption of the system, and improve the effect of cold and heat integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

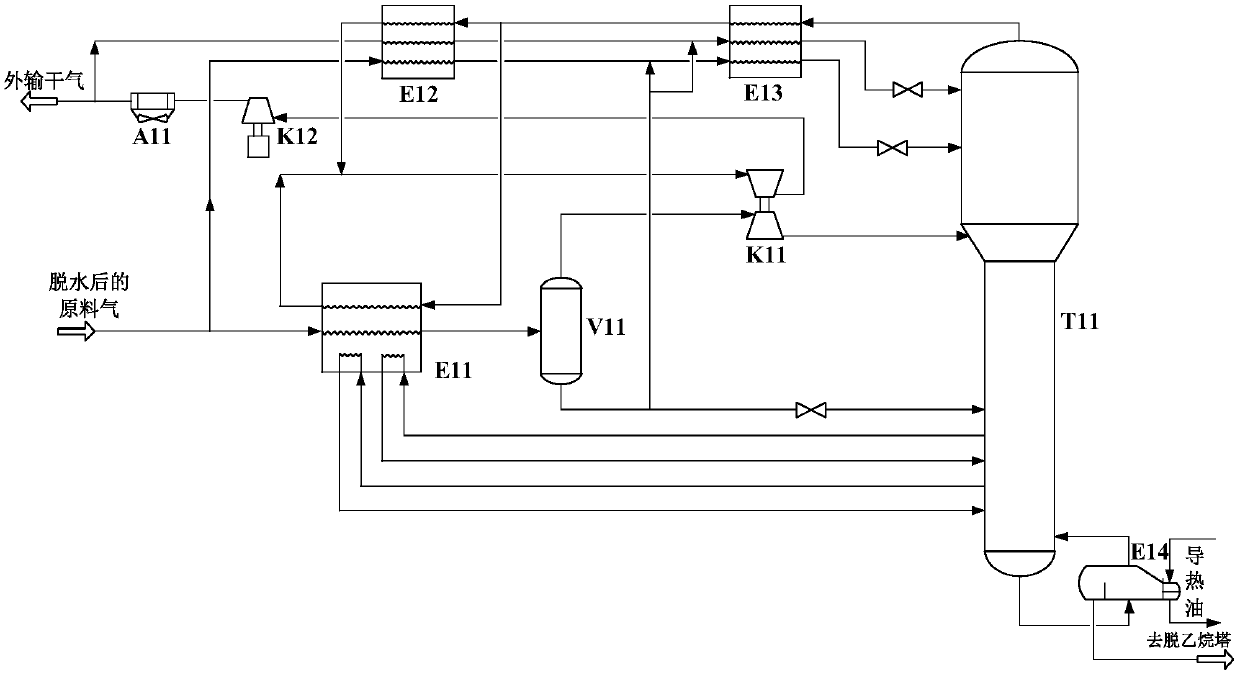

[0050] Embodiment 1 of the present invention is attached Figure 4 As shown, the raw material gas composition and calculation basic data are as follows:

[0051] Raw gas processing scale: 500×10 4 m 3 / d

[0052] Raw gas pressure: 5.5MPa

[0053] Entry temperature: 38°C

[0054] Dry gas output pressure: ≥5.0MPa

[0055] Output pressure of ethane product: ≥2.0MPa

[0056] Compressor adiabatic efficiency: 75% (including external compressor, refrigeration compressor, booster end of expansion unit)

[0057] Isentropic efficiency at the expansion end of the expansion unit: 85%

[0058] The raw gas composition is shown in Table 1.

[0059] Table 1 Example 1 Feed gas composition

[0060] components

N 2

CO 2

C 1

C 2

C 3

iC 4

mol%

6.2329

1.0000

81.5141

6.9354

2.5627

0.4177

components

c 4

iC 5

c 5

C6

C 7 +

h 2 o

mol%

0.7013

0.1650

0.1345

0.1236

...

Embodiment 2

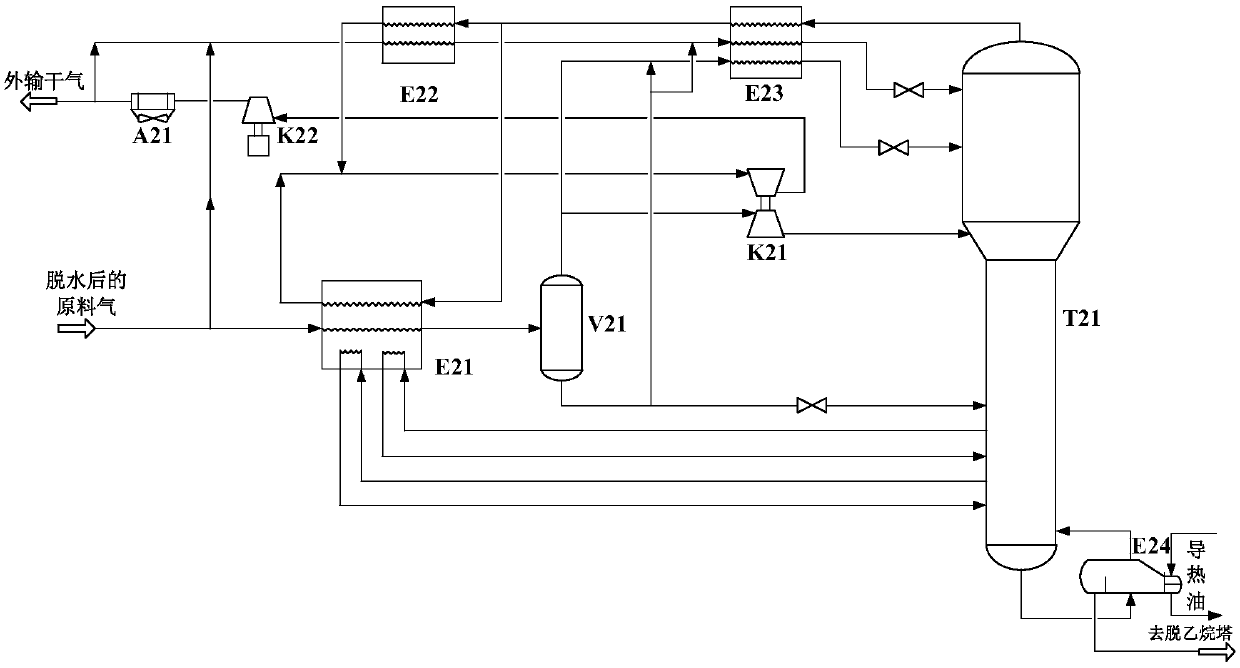

[0069] Embodiment 2 of the present invention is attached Figure 5 As shown, the raw material gas composition and calculation basic data are as follows:

[0070] Raw gas processing scale: 500×10 4 m 3 / d

[0071] Raw gas pressure: 5.0MPa

[0072] Entry temperature: 38°C

[0073] Dry gas output pressure: ≥5.0MPa

[0074] Output pressure of ethane product: ≥2.0MPa

[0075] Compressor adiabatic efficiency: 75% (including external compressor, refrigeration compressor, booster end of expansion unit)

[0076] Isentropic efficiency at the expansion end of the expansion unit: 85%

[0077] The raw gas composition is shown in Table 2.

[0078] Table 2 Example 2 feed gas composition

[0079] components

N 2

CO 2

C 1

C 2

C 3

iC 4

mol%

4.2227

1.0000

77.4702

10.8874

4.0661

0.5768

components

c 4

iC 5

c 5

C6

C 7 +

h 2 o

mol%

0.9806

0.2542

0.2175

0.1642

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com