Operation method suitable for ice-and-snow prevention, breaking and melting of rail facility and monitoring system

A track and facility technology, applied in the field of operation methods and monitoring systems, can solve problems such as low efficiency, inability to go online, inability to adapt, etc., and achieve high efficiency, save material costs, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

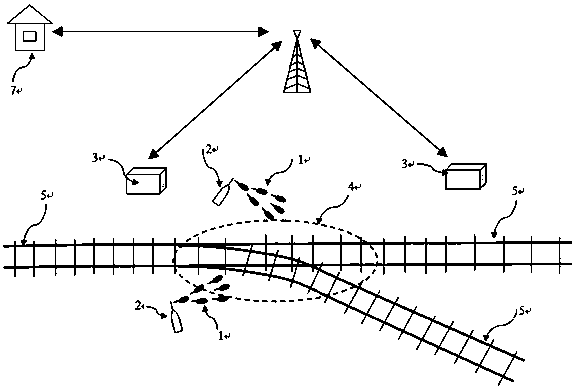

[0050] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

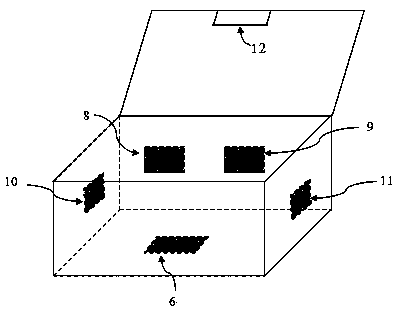

[0051] The storage box of the present invention is used to store storage containers (spray tanks) for anti-icing, ice-breaking, and snow-melting liquid medicines, and complies with the American FM standard, the American Occupational Safety and Health Administration (OSHA) 1910.106 standard 2000 version, and the National Fire Protection Association (NFPA) standard , China GB / T 28920-2012, Q / 320205 XBB001-2014 standards. The storage box is made of high-strength laminates, with a load-bearing capacity of up to 200 kg. The high-strength laminates can effectively prevent the laminates from being deformed and broken due to insufficient bearing capacity, and the container will slip and break, which meets the explosion-proof requirements.

[0052] The storage box has the functions of rainproof, flame retardant and acid and alkali corrosion resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com