Dip-molding and leveling method and device, and dip-molding method for micro-precision devices

A leveling and dipping technology, which is applied to coatings, tubular objects, household appliances, etc., can solve the problems of no rubber accumulation, uneven leveling of liquid slurry, disadvantages, etc., to improve reproducibility and consistency , high process flexibility and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Slurry preparation: prepare liquid PVC slurry, put it into a mixer and stir evenly to obtain the slurry;

[0043] (2) Stand still and vacuumize: After the slurry is left to stand for 1h, put it into a vacuum box to vacuumize and remove the air bubbles in the slurry;

[0044] (3) Mold preheating: Preheat the mold with a diameter of 0.4mm to 120°C, test the temperature of the mold through the temperature sensing line, and obtain the preheated mold;

[0045] (4) dipping: the manipulator clamps the preheated mold and vertically immerses it in the slurry in the glue tank, and takes it out after 3 seconds by the timer to obtain the mold coated with slurry;

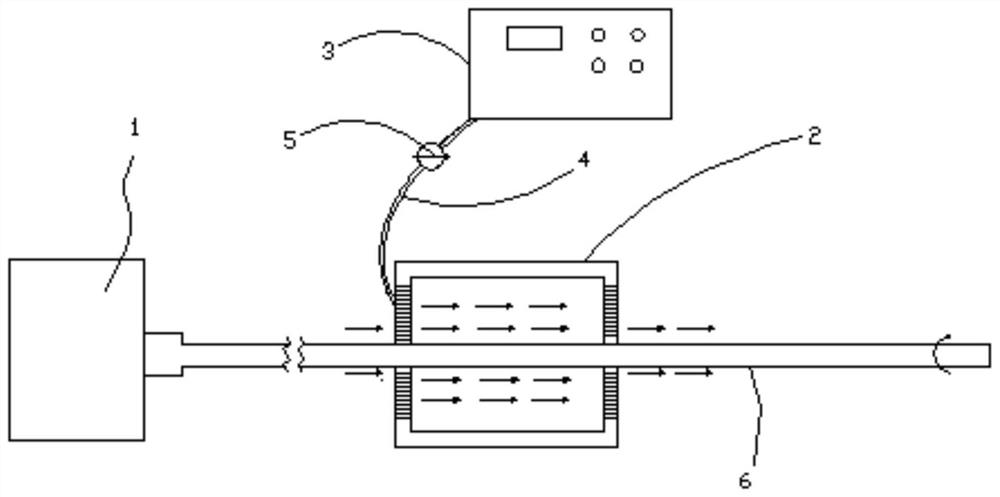

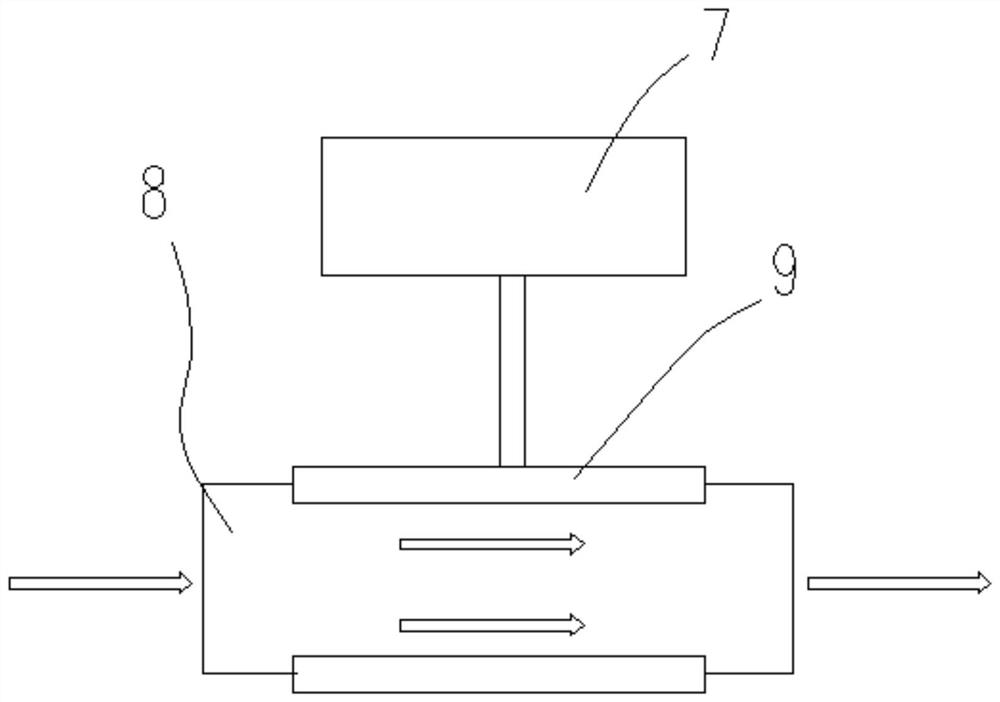

[0046] (5) Leveling: The manipulator drives the coated mold into the leveling cavity where there is an airflow parallel to the mold. The centrifuge drives the coated mold to rotate at a speed of 60rpm / min. The wind speed of the airflow is 3m / s, and the flow rate is obtained. Mold after flattening.

[0047] (6) Curin...

Embodiment 2

[0050] (1) Slurry preparation: prepare addition-type liquid silicone slurry, put it into a mixer and stir evenly to obtain the slurry;

[0051] (2) standing vacuum: after the slurry is left to stand for 1.2h, put it into a vacuum box and vacuumize to remove the air bubbles in the slurry;

[0052] (3) Mold preheating: Preheat the mold with a diameter of 0.3mm to 60°C, test the temperature of the mold through the temperature sensing line, and obtain the preheated mold;

[0053] (4) dipping: the manipulator clamps the preheated mold and vertically immerses it in the slurry in the glue tank, and takes it out after 1 second with the timer to obtain the mold coated with slurry;

[0054] (5) Leveling: The manipulator drives the coated mold into the leveling chamber where there is an airflow parallel to the mold. The centrifuge drives the coated mold to rotate at a speed of 120rpm / min. The wind speed of the airflow is 20m / s, and the flow rate is obtained. Mold after flattening.

[0...

Embodiment 3

[0058] (1) Slurry preparation: prepare polycondensation-type liquid silicone slurry, put it into a mixer and stir evenly to obtain the slurry;

[0059] (2) Static vacuuming: After the slurry is left to stand for 0.5h, put it into a vacuum box and vacuumize to remove the air bubbles in the slurry;

[0060] (3) Mold preheating: Preheat the mold with a diameter of 0.6mm to 60°C, test the temperature of the mold through the temperature sensing line, and obtain the preheated mold;

[0061] (4) dipping: the manipulator clamps the preheated mold and vertically immerses it in the slurry in the glue tank, and takes it out after 2 seconds by the timer to obtain the mold coated with slurry;

[0062] (5) Leveling: The manipulator drives the coated mold into the leveling cavity where there is an airflow parallel to the mold. The centrifuge drives the coated mold to rotate at a speed of 90rpm / min, and the wind speed of the airflow is 10m / s. Mold after flattening.

[0063] (6) Curing at co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com