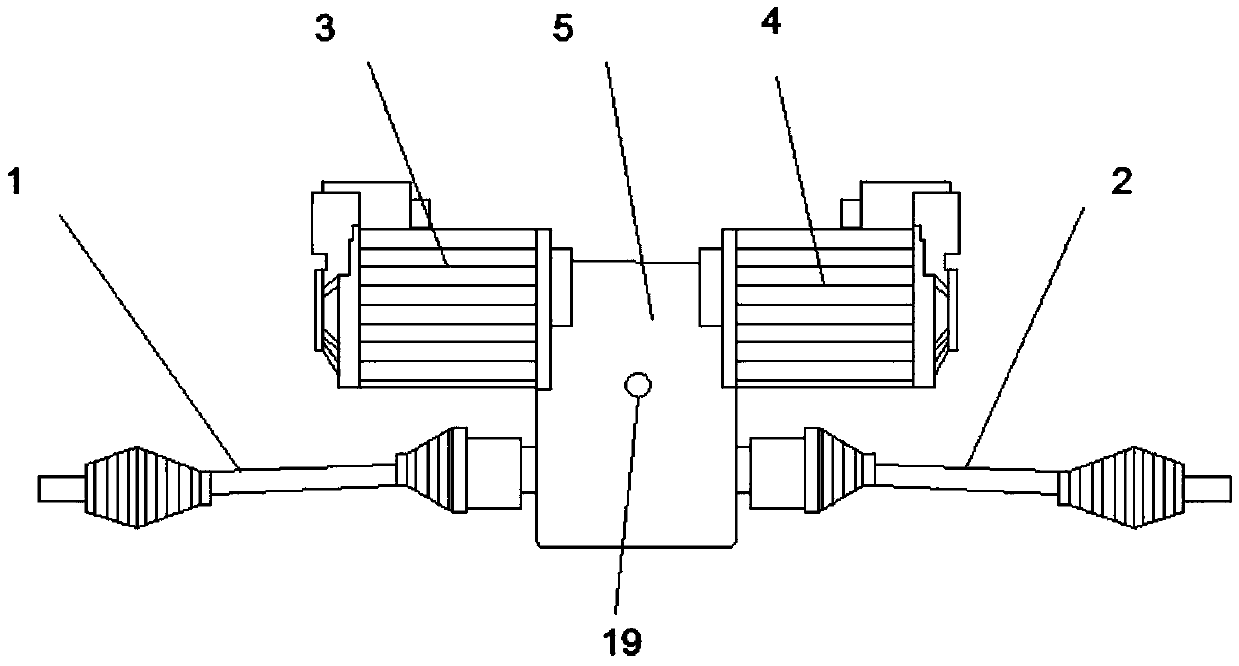

Two-motor driving system

A dual-motor drive and drive shaft technology, which is applied in the direction of electric power devices, power devices, control devices, etc., can solve problems such as difficult long-axis layout, vehicle driving hazards, and oversized motors, so as to facilitate the overall layout. Improvement of process performance and effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

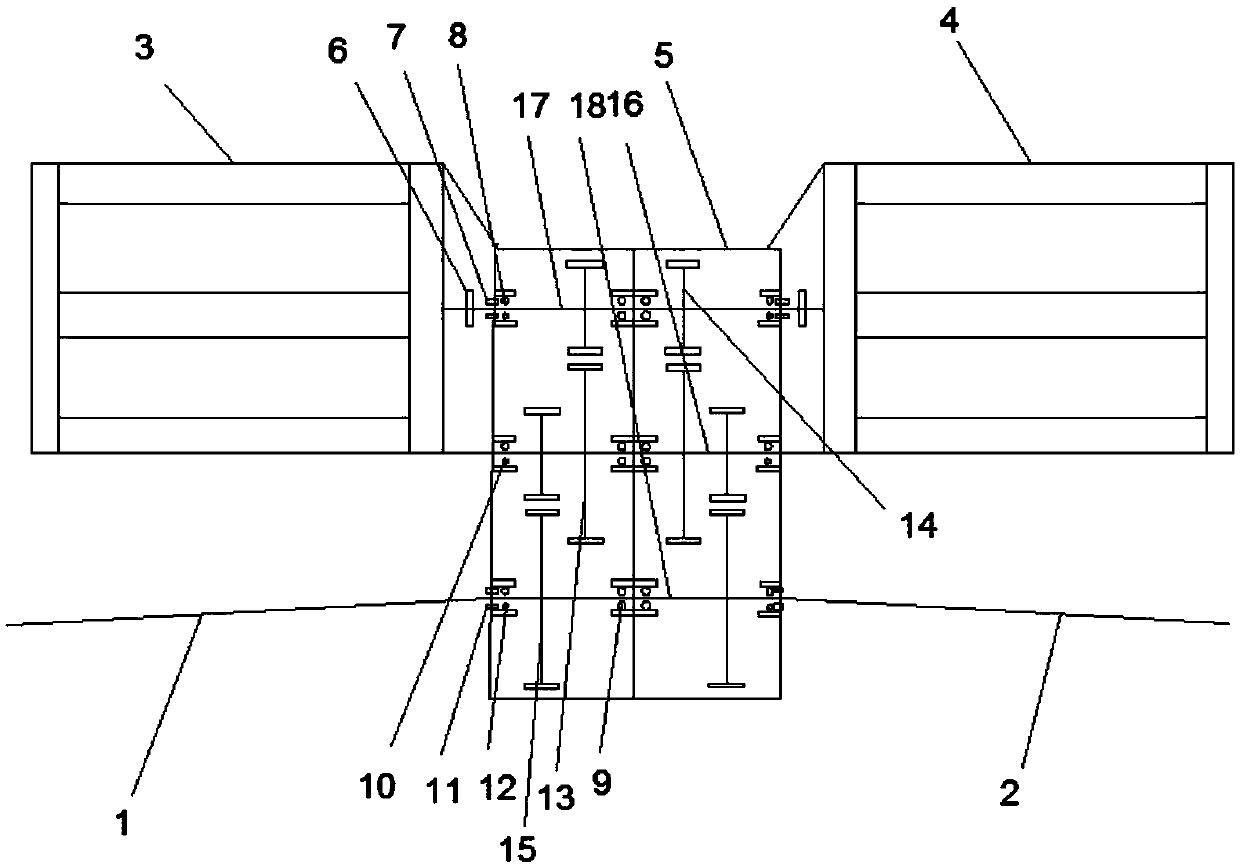

[0020] As a preferred embodiment of the present invention, the first gear 14 meshes with the second gear 13 , and the second gear 13 meshes with the third gear 15 .

[0021] As a preferred embodiment of the present invention, the first sealing ring 7 and the second sealing ring 11 are both made of soft rubber materials.

[0022] As a preferred embodiment of the present invention, one side of the gearbox 5 is provided with a breathing hole 19, and the diameter of the breathing hole 19 is 10-30 mm.

[0023] As a preferred embodiment of the present invention, the left motor 3 and the right motor 4 are stepping motors, and the models are exactly the same.

[0024] As a preferred embodiment of the present invention, the first gear 14 , the second gear 13 and the third gear 15 are all helical gears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com