Method for predicting degree that rice is contaminated by aspergilli based on electronic nose

An Aspergillus fungus and electronic nose technology, applied in the field of microbial detection, can solve the problems of complex and time-consuming, low efficiency and high cost of fungal detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for quickly predicting the degree of rice infection by Aspergillus jaundice based on electronic nose, its steps are as follows:

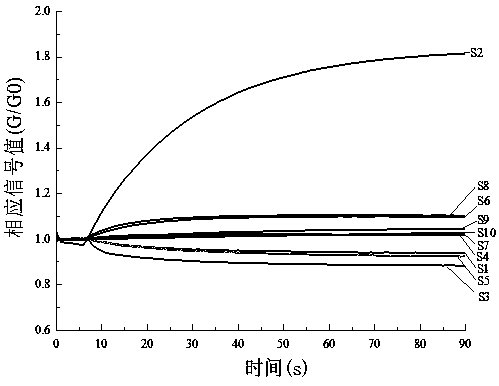

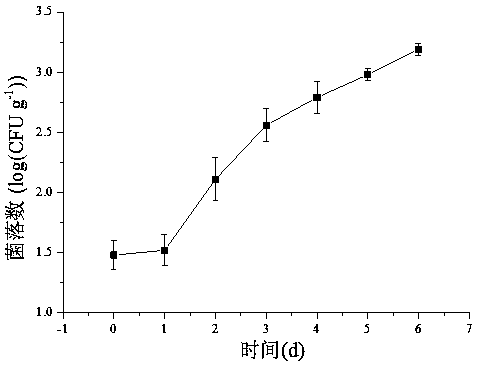

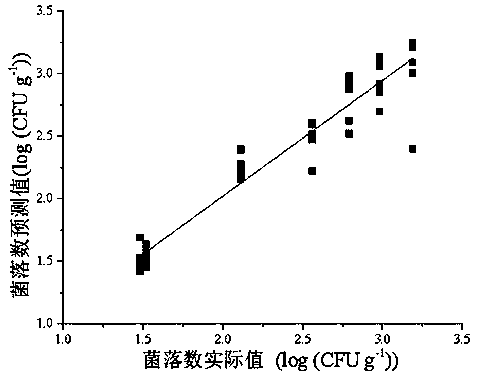

[0035] (1) Take the commercially available Jiangsu Xingjia rice as the experimental object, and place it at 110mW s / cm 2 After sterilizing for 30-60min under the ultraviolet lamp, 7 batches of rice samples were selected to inoculate 0.2mL concentration of 10 7CFU / mL Aspergillus leucobacter spore suspension, and stored at 28±1°C, 85% relative humidity. A batch of rice samples was taken out every 24 hours and placed in a container at room temperature and sealed. A total of 7 batches were taken out, numbered 0d, 1d, 2d, 3d, 4d, 5d, and 6d. The volume of the container is 500mL. After the sample is left to stand for 60 minutes, the headspace gas in the sealed container is saturated to obtain the headspace gas; before the start of each electronic nose test, the electronic nose system is cleaned with dry and clean air, and the cleaning met...

Embodiment 2

[0045] A method for quickly predicting the degree of rice infection by Aspergillus fumigatus based on electronic nose, its steps are as follows:

[0046] (1) Take the commercially available Jiangsu Xingjia rice as the experimental object, and place it at 110mW s / cm 2 After sterilizing for 30-60min under the ultraviolet lamp, 7 batches of rice samples were selected to inoculate 0.2mL concentration of 10 7 CFU / mL Aspergillus fumigatus spore suspension, and stored at 28±1°C, 85% relative humidity. A batch of rice samples was taken out every 24 hours and placed in a container at room temperature and sealed. A total of 7 batches were taken out, numbered 0d, 1d, 2d, 3d, 4d, 5d, and 6d. The volume of the container is 500mL. After the sample is left to stand for 60 minutes, the headspace gas in the sealed container is saturated to obtain the headspace gas; before the start of each electronic nose test, the electronic nose system is cleaned with dry and clean air, and the cleaning met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com