Composite and high-conductivity cathode steel bar

A cathode steel rod, high-conductivity technology, applied in the field of cathode steel rods, can solve the problems of large physical pressure drop, high current density of cathode carbon blocks, and reduced current efficiency, so as to reduce the rate of cathode wear, prolong cathode life, and improve The effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

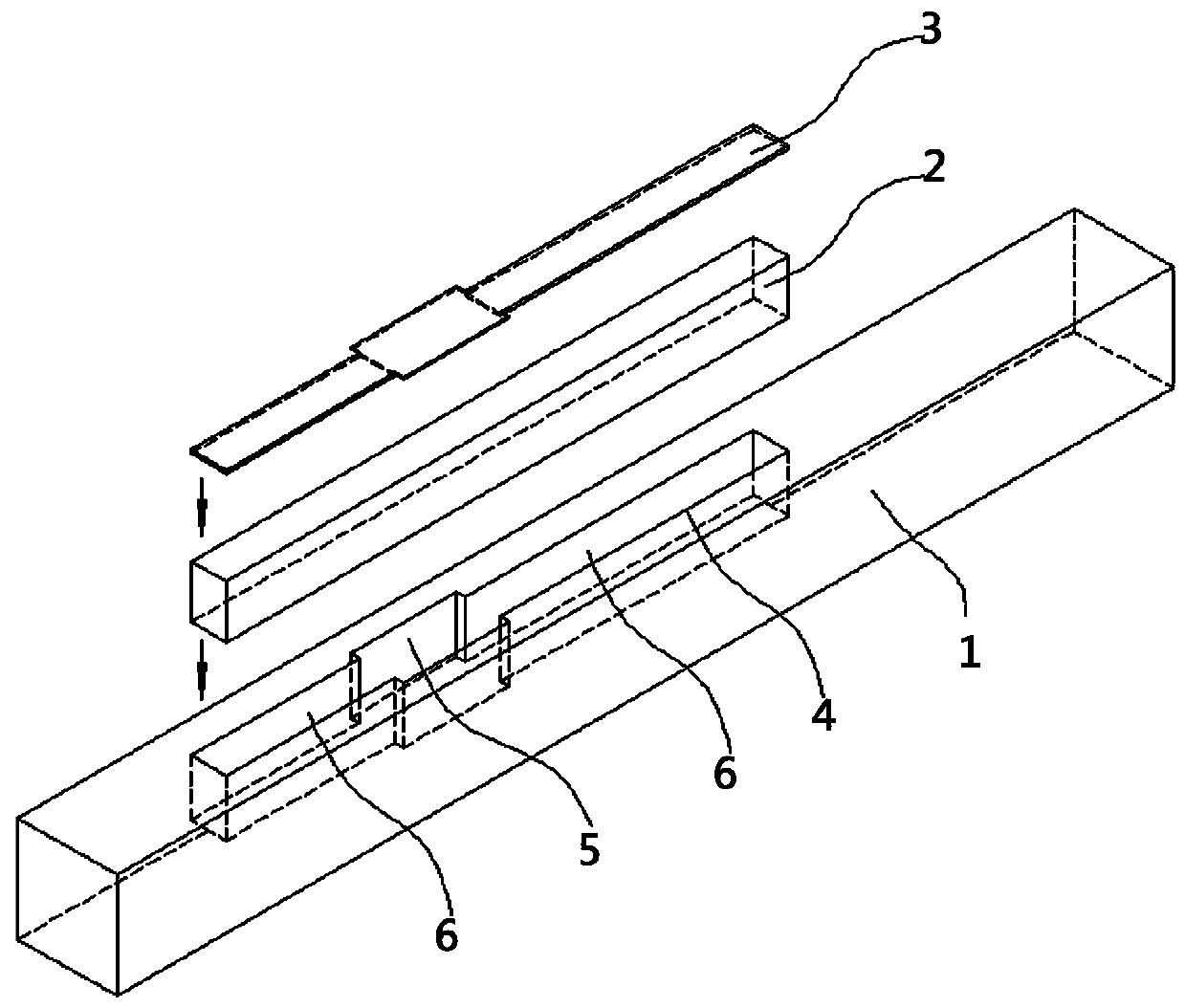

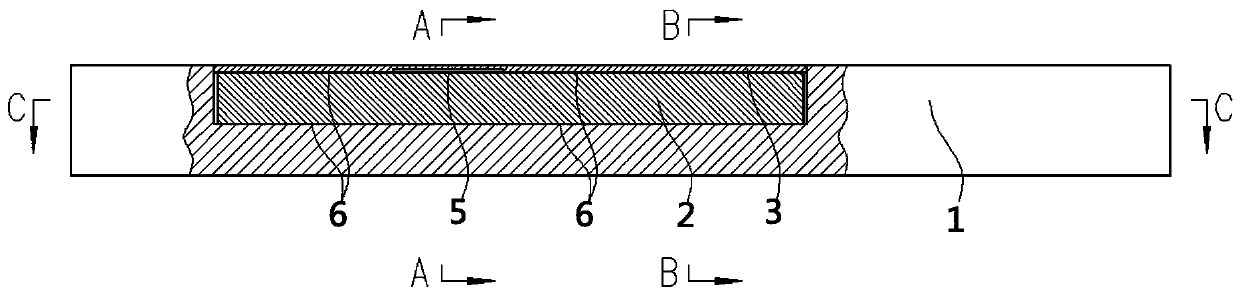

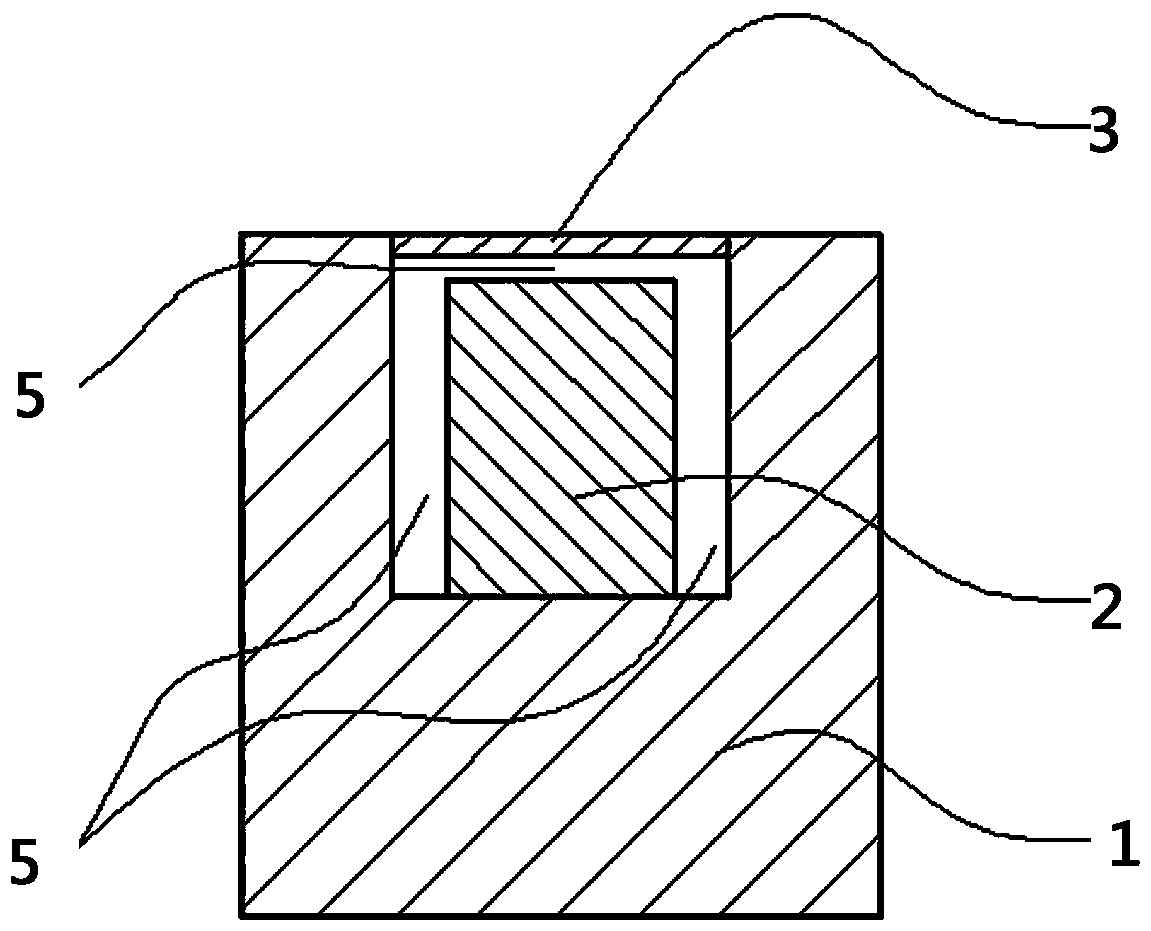

[0035] Such as Figure 1-5 As shown, a composite, high-conductivity cathode steel rod of the present invention comprises a conductive matrix 1, a cavity 4 with an opening is provided in the conductive matrix 1, a high-conductivity body 2 is provided in the cavity 4, and a cavity 4 opening is provided with There is a sealing body 3, and a non-conductive area 5 is provided between the high-conductor 2, the conductive base 1 and the sealing body 3 in the cavity 4, and the contact part between the high-conductor 2 and the conductive base 1 and the sealing body 3 is a conductive area 6 .

[0036] The non-conductive region 5 is obtained by forming a physical gap between the high conductor 2 , the conductive base 1 and the sealing body 3 .

[0037] The cavity 4 composed of the conductive base 1 and the sealing body 3 is fully airtight.

[0038] The material of the conductive base 1 is steel, and the material of the high electrical conductor is copper.

[0039] The cross section of...

Embodiment 2

[0041] In Example 1, there are two non-conductive domains. The cavity 4 composed of the conductive base 1 and the sealing body 3 is semi-airtight, and the part without airtightness is in the conductive area. The material of the conductive base 1 is iron, and the high conductor is aluminum- steel composite. The non-conductive region 5 is obtained by keeping the internal cross-sections of the conductive base 1 and the sealing body 3 unchanged, while reducing the partial cross-section of the high-conductor 2 . Vent holes are provided at the conductive base 1 at the non-conductive region 5 . The cross section of the conductive base 1 is circular, and the cross section of the high conductor 2 is circular. The non-conductive area 5 completely surrounds the high-conductor 2, and a non-conductive substance is provided between the bottom of the high-conductor 2 and the conductive base 1. One side of the high-conductor 2 is in contact with the conductive base 1, and the other side of t...

Embodiment 3

[0043] In Example 1, the high conductor is a silver-steel composite material, the cross section of the conductive matrix 1 is semicircular, the cross section of the high conductor 2 is semicircular, and the connection between the conductive matrix 1 and the sealing body 3 is bonding. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com