Making method of self-thermal insulation external wall panel for fabricated building

A technology of external hanging wall panels and manufacturing methods, which is applied in the direction of thermal insulation and building components, and can solve problems such as incompatibility between extruded plastic boards and cement, potential safety hazards, and complicated construction, and achieve the effect of eliminating cold and thermal bridges and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

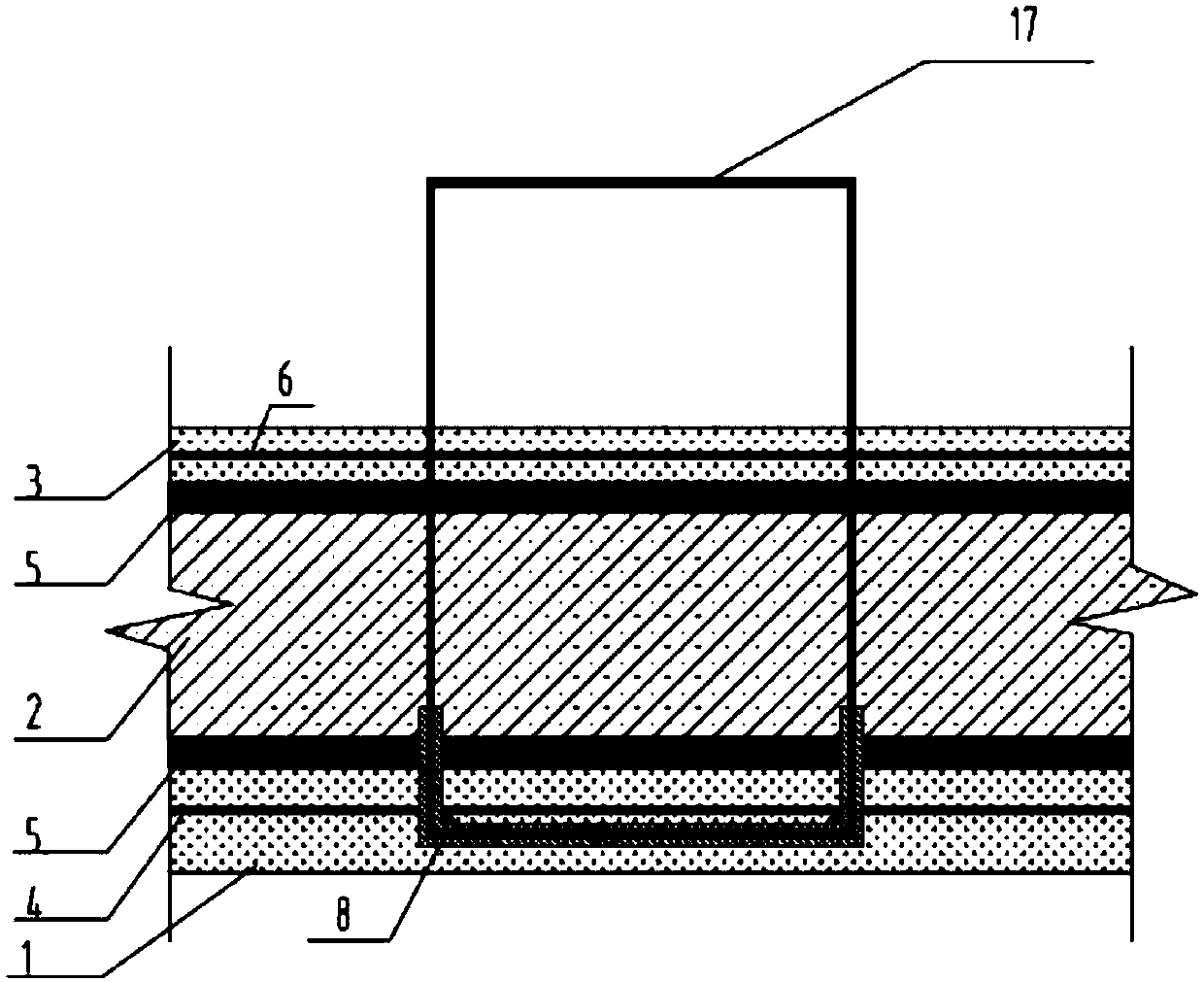

[0034] Such as figure 1 As shown, the manufacturing method of self-insulating external wall panels in prefabricated buildings includes the following steps:

[0035] (1) making the first surface reinforcement layer 1: laying cement slurry or anti-cracking mortar on the steel wire mesh 6 as the first surface reinforcement layer 1;

[0036] (2) Make the thermal insulation layer and the concrete bonding layer: the mineral fiber board 2 is placed on the unsolidified cement slurry or anti-crack mortar, the mineral fibers on the mineral fiber board 2 are all perpendicular to the first surface reinforcement layer 1, and the first surface The cement slurry on the reinforcement layer 1 wraps one end of the mineral fiber on the mineral fiber board 2 to generate a firm concrete bonding layer 5, so that the first surface reinforcement layer 1 and the mineral fiber board 2 are firmly bonded together;

[0037] (3) Make the second surface reinforcement layer 3 and the concrete bonding layer:...

Embodiment 2

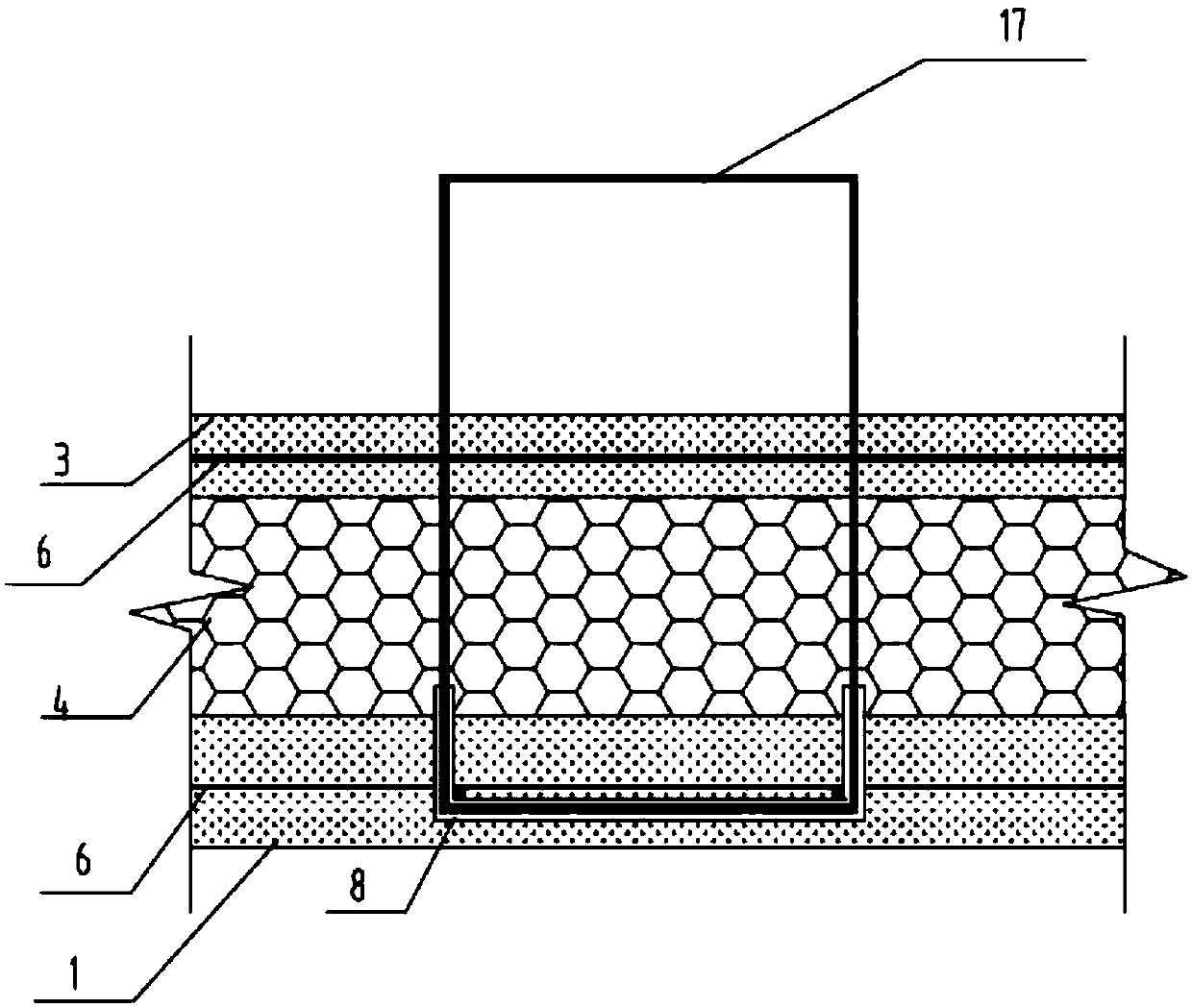

[0040] Such as figure 2 As shown, the manufacturing method of self-insulating external wall panels in prefabricated buildings includes the following steps:

[0041] (1) making the first surface reinforcement layer 1: laying cement slurry or anti-cracking mortar on the steel wire mesh 6 as the first surface reinforcement layer 1;

[0042] (2) Make the insulation layer: pour the insulation slurry on the first surface reinforcement layer 1 to make the insulation board 4;

[0043] (3) Make the second surface reinforcement layer 3: Lay steel wire mesh 6 or fiber mesh cloth and cement slurry or anti-cracking mortar on the insulation board 4, as the second surface reinforcement layer 3, the first surface reinforcement layer 1, heat preservation The board 4 and the second surface reinforcement layer 3 are combined together to form a self-insulating wallboard;

[0044] (4) Set the anchoring external reinforcement: the upper end and the lower end of the self-insulation wallboard are ...

Embodiment 3

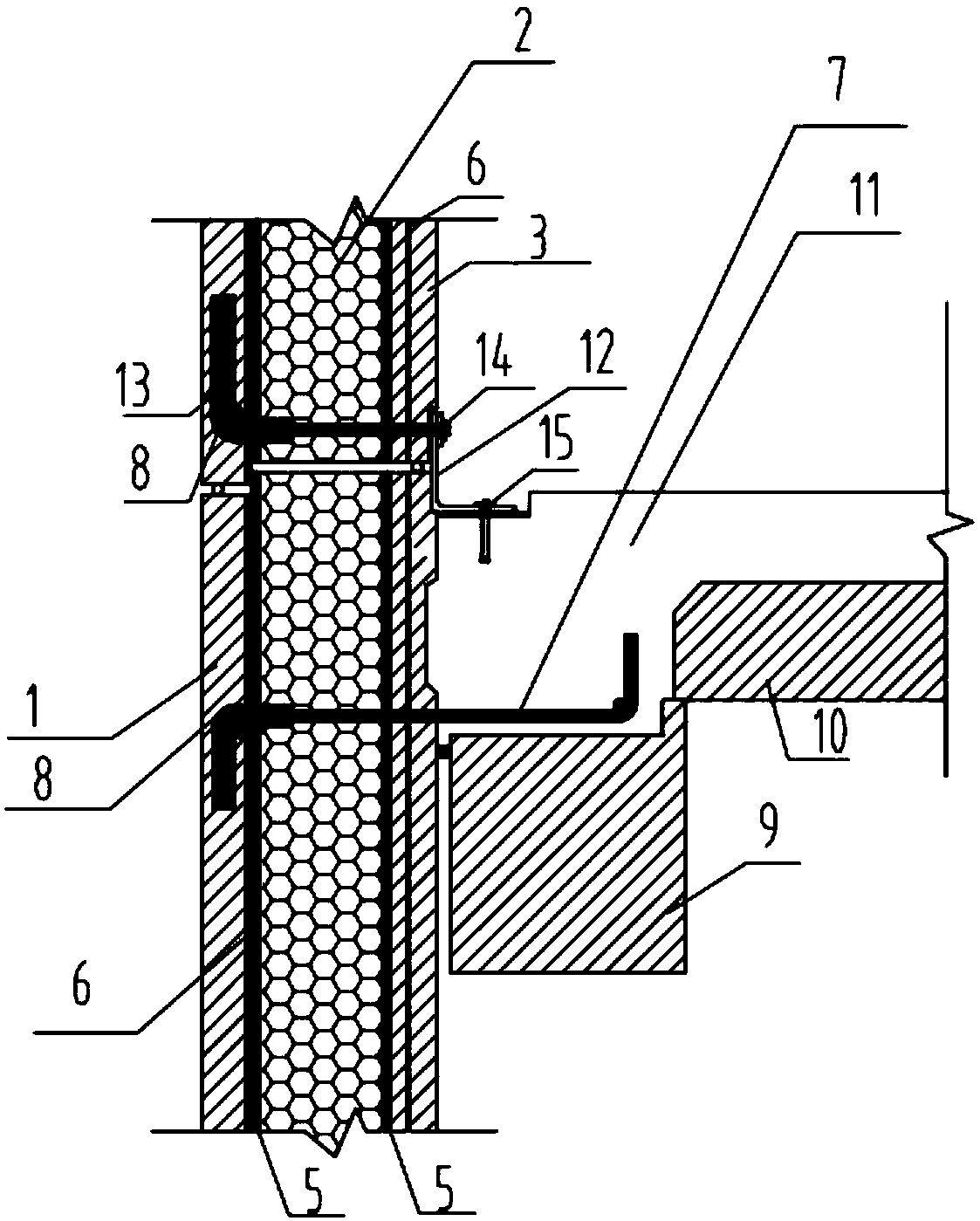

[0046] Such as image 3 As shown, the manufacturing method of self-insulating external wall panels in prefabricated buildings includes the following steps:

[0047] (1) making the first surface reinforcement layer 1: laying cement slurry or anti-cracking mortar on the steel wire mesh 6 as the first surface reinforcement layer 1;

[0048] (2) Make the thermal insulation layer and the concrete bonding layer: the mineral fiber board 2 is placed on the unsolidified cement slurry or anti-crack mortar, the mineral fibers on the mineral fiber board 2 are all perpendicular to the first surface reinforcement layer 1, and the first surface The cement slurry on the reinforcement layer 1 wraps one end of the mineral fiber on the mineral fiber board 2 to generate a firm concrete bonding layer 5, so that the first surface reinforcement layer 1 and the mineral fiber board 2 are firmly bonded together;

[0049] (3) Make the second surface reinforcement layer 3 and the concrete bonding layer:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com