A cooling brake piston

A technology of pistons and piston rods, applied in the field of heat dissipation brake pistons, which can solve the problems of reduced vehicle braking capacity, smaller gaps, and poor pistons, and achieve good heat dissipation, high-efficiency heat dissipation, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

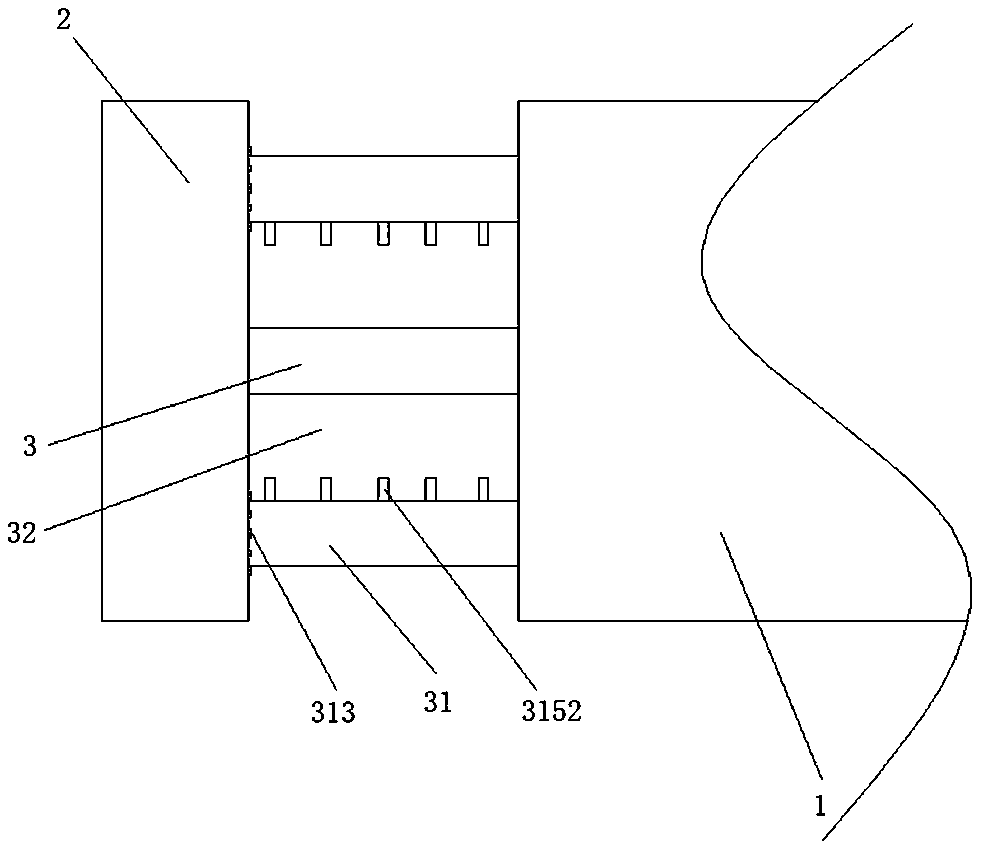

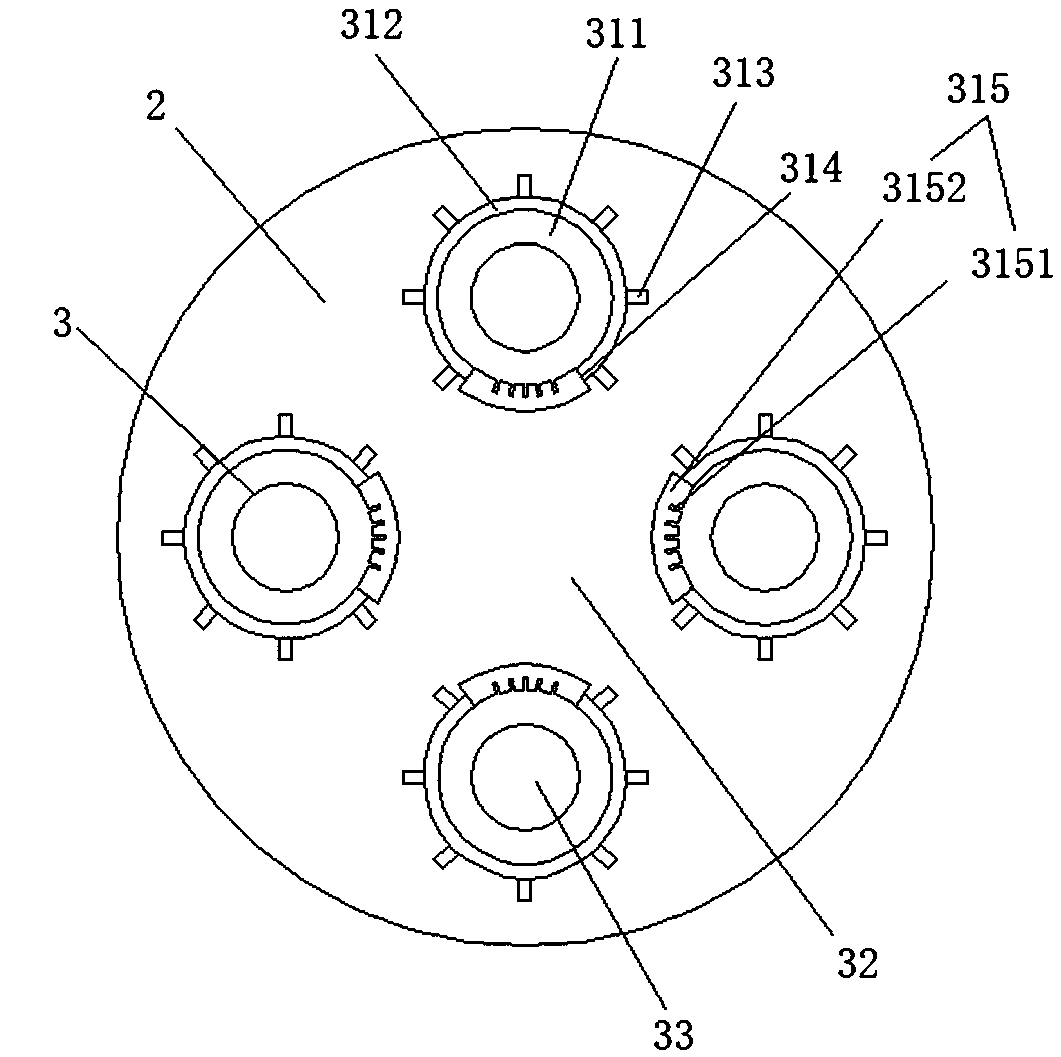

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022] Such as figure 1 , 2 The shown heat dissipation brake piston includes a piston rod formed by cold extrusion and a nose at the front end of the piston rod for connecting the brake block. The disc-shaped installation section 2 connected to the brake block and the heat dissipation section 3 located between the connection section 1 and the installation section 2, the heat dissipation section 3 includes a plurality of circumferential distributions that are conducive to supporting the stressed structure, and the two ends are respectively connected to the connection section 1 With the cooling columns 31 of the installation section 2 , the space between the plurality of cooling columns 31 forms a fluid passage 32 . When the brake is working, the contact and friction between the brake block and the wheel generates heat, which is transferred from the mounting section 2 to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com