Magnetic conductive sheet for wireless charger and preparation method thereof

A technology of wireless charger and magnetic conductive sheet, which is applied in the manufacture of inductors/transformers/magnets, circuits, magnets, etc. It can solve the problems of poor insulation treatment effect, reduce eddy current effect, consume working magnetic field, etc., and achieve good insulation treatment effect , uniform distribution spacing, and the effect of reducing the eddy current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

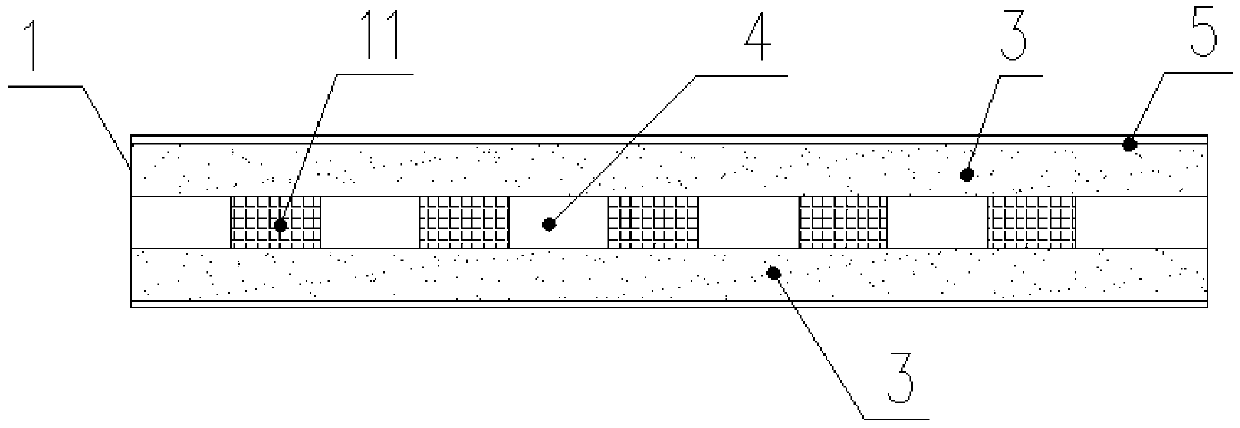

[0040] Such as figure 1 As shown, the magnetic conductive sheet is set as a single-layer first magnetic sheet structure, the first magnetic sheet includes an adhesive layer and the first magnetic fragments adhered above the adhesive layer, the first A protective film is attached to the upper surface of the magnetic fragments, and a release film is attached to the lower side of the adhesive layer.

Embodiment 2

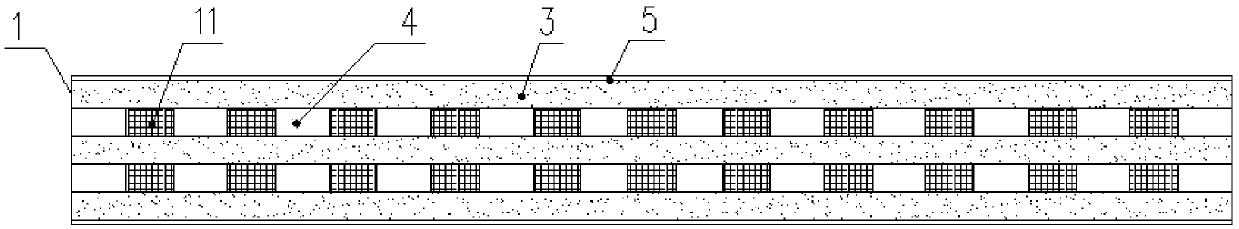

[0042] Such as figure 2 As shown, the magnetic conductive sheet is arranged as a laminated structure of at least two layers of first magnetic thin sheets, and the first magnetic thin sheets of each layer are adhered by an adhesive layer to form interlayer insulation; the magnetic conductive sheet is most A protective film is attached to the upper surface of the first magnetic fragments in the first magnetic sheet at the uppermost layer, and a release film is attached to the lower side of the adhesive layer in the first magnetic sheet at the lowermost layer.

[0043] In the above-mentioned embodiment 1 and embodiment 2, the material of the first magnetic fragments is iron-based amorphous or nanocrystalline; the release film is formed as a whole when the adhesion layer is manufactured, specifically, the release film The combination of film and adhesive layer is OCA acrylic tape, and the adhesive layer is a conventional double-sided adhesive layer.

Embodiment 3

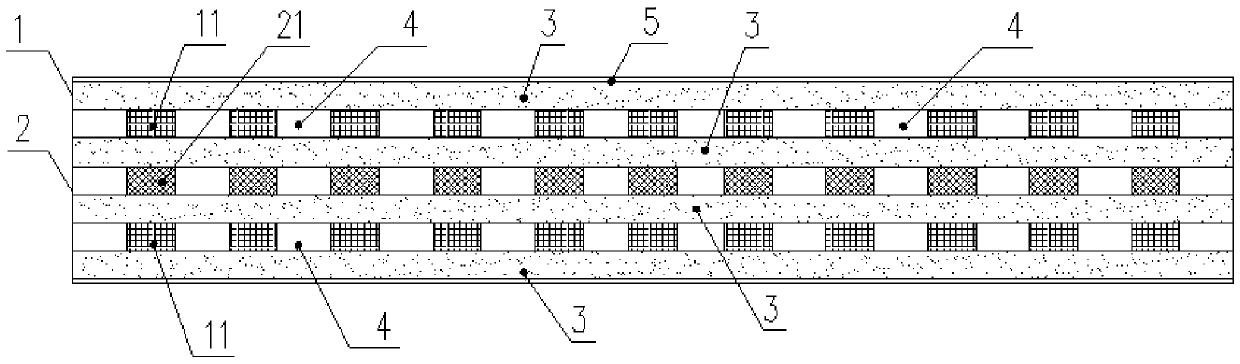

[0045] Such as Figure 3 to Figure 5 As shown, the magnetically permeable sheet also includes a second magnetic sheet, the first magnetic sheet has a first magnetic permeability, and the second magnetic sheet has a second magnetic permeability; A laminated combination form of a magnetic sheet and a second magnetic sheet, the second magnetic sheet is adhered to the first magnetic sheet through an adhesive layer to form interlayer insulation; the uppermost layer of the magnetic conductive sheet A protective film is attached to the upper surface of the magnetic fragments in the magnetic sheet, and a release film is attached to the lower side of the adhesion layer in the magnetic sheet at the bottom layer.

[0046] Wherein, the second magnetic sheet includes a plurality of separated second magnetic fragments, and an air medium is filled between the second magnetic fragments to insulate the second magnetic fragments from each other.

[0047] In addition, the second magnetic flakes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone base diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com