Framework of iron negative electrode venting separator in alkaline iron-nickel battery

A technology of iron-nickel storage battery and exhaust separator, which is applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, nickel storage battery, etc. It can solve the problems affecting the cycle life of the battery, achieve fast charging and discharging, excellent electrical performance, long cycle life, The effect of making the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

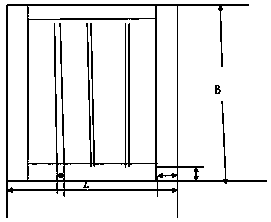

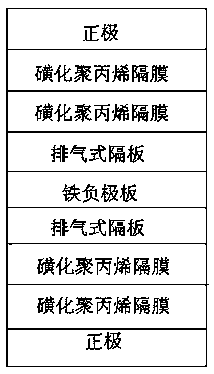

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0021] A structure of an iron negative exhaust separator in an alkaline iron-nickel storage battery, characterized in that it comprises the following steps:

[0022] (1) Prepare the sulfonated polypropylene diaphragm that needs to be assembled;

[0023] (2) Prepare the vented partitions that need to be assembled;

[0024] (3) Prepare the required iron negative plate.

[0025] The thickness of the sulfonated polypropylene diaphragm is 0.1-0.5 mm.

[0026] The material of the vented partition is polyethylene, polyvinyl chloride, polypropylene, polytetrafluoroethylene, ABS, nylon plastic, and the thickness of the vented partition is 0.1-0.3 mm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com