Waterproof sock cover completely fit with surface of upper

A waterproof socks and surface fitting technology, which is applied to shoe uppers, boot legs, reinforcements, etc., can solve the problems of waterproof socks folds, etc., and achieve the effect of good molding effect, reducing the probability of rework and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

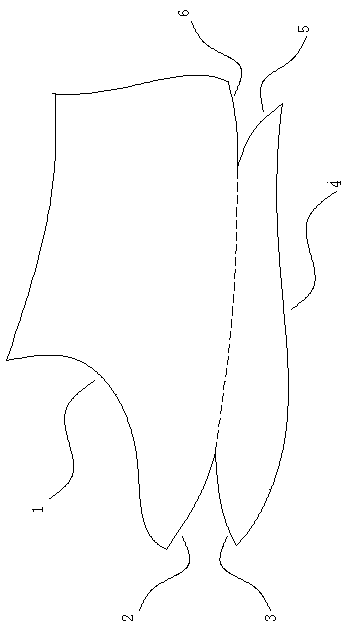

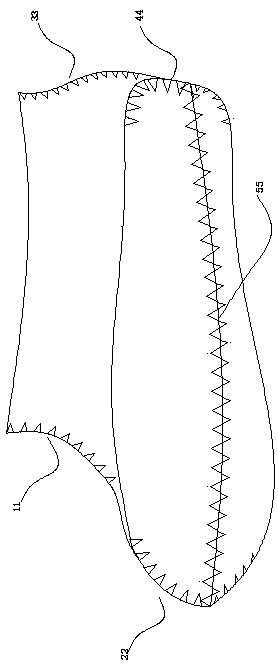

[0018] In this example, if figure 1 As shown, the front side and the rear side of the unfolded sock are respectively provided with sutures, and the upper and lower gaps of the sutures are arc-shaped connections. The actual situation. Although the straight-line notch can also achieve the purpose of sewing the bottom surface and the inner lining of the sock, but the joint is due to a right-angle transition, and in this embodiment, the upper notch is bent upwards, and the lower notch is bent downwards. The stitching effect is obviously better than the right-angled transition. , making the joint surface more smooth and fit. In this embodiment, the angle between the upper front gap and the lower front gap, and the arc openings between the upper rear gap and the lower rear gap is 20° to 30°, so as to ensure a smooth bonding surface during bonding.

Embodiment 2

[0020] In the present embodiment, the suture openings are respectively located at the toe position and the heel position of the sock cover, and the bottom surface can be bent inward along the fold line, and the suture lines of the upper gap and the lower notch are respectively located at the two sides of the bottom surface and the bending extension line of the sock cover inner lining. end. In this way, the upper gap 2 on the front side and the lower gap 3 on the front side, the lower gap 5 on the rear side and the upper gap 6 on the rear side of the front side suture opening are respectively at the bottom surface and the inside of the sock cover when the sewing position is the same as the bending position of the bottom surface. They are in contact with each other and connected by stitching, so that the bending line and the stitching line overlap, which further increases the wearing comfort and the force is more reasonable.

[0021] As a preference, the stitched front opening e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com