Preparation method for aerogel-hydrogel compound drug carrier and prepared carrier

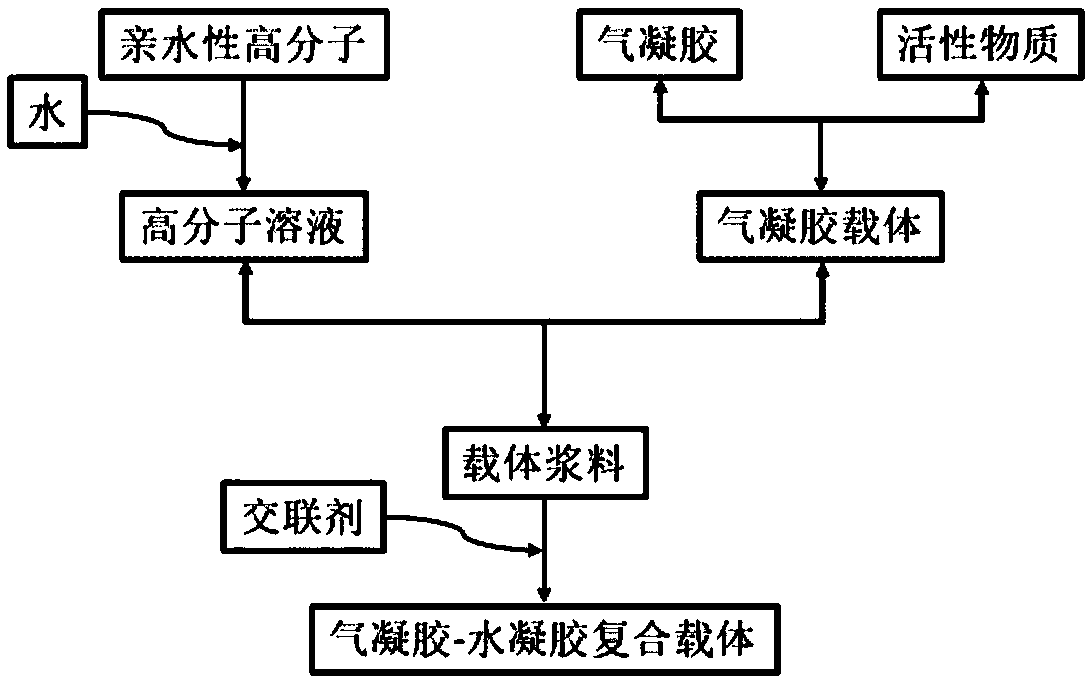

An aerogel and hydrogel technology, applied in the field of preparation methods and prepared carriers, can solve the problems of limited load capacity of hydrogels and low mechanical properties of aerogels, and achieve improved diffusion uniformity and easy intelligence. and controlled release, the effect of increasing the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of an airgel-hydrogel composite drug carrier, comprising the following steps:

[0042] (1) 5g of sodium alginate and 95g of water were magnetically stirred and mixed for 3 hours at a temperature of 80° C. to form a transparent solution;

[0043] (2) 1g of airgel powder is mixed with 3g of borage oil, and mixed with the transparent solution obtained in step (1) to obtain an airgel-borage oil mixture; the airgel powder used in this example is SiO 2 Aerogel;

[0044] (3) The airgel-borage oil mixture was mixed for 3 hours by ball milling;

[0045] (4) Mix 5g CaCl with magnetic stirring 2 Mix with 200g of water to form a transparent solution;

[0046] (5) Add dropwise the mixture after ball milling in step (3) to CaCl through a dropper 2 In the solution, the airgel-hydrogel composite drug carrier is formed by curing and cross-linking.

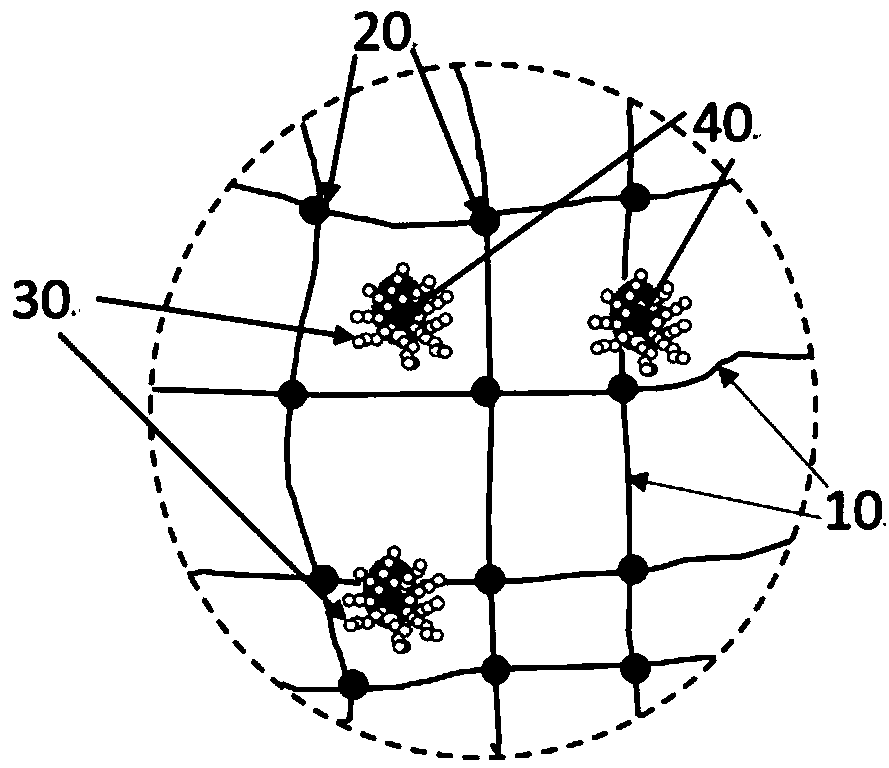

[0047] Experimental results: figure 2 It is the principle diagram of the airgel-hydrogel composite drug carrier...

Embodiment 2

[0050] A preparation method of an airgel-hydrogel composite drug carrier, comprising the following steps:

[0051] (1) 10 g of polyvinyl alcohol and 95 g of water were magnetically stirred and mixed for 3 hours at a temperature of 95° C. to form a transparent solution;

[0052] (2) 1g of airgel powder is mixed with 3g of alfalfa extract oil, mixed with the transparent solution obtained in step (1) to obtain an airgel-borage oil mixture; the airgel powder used in this embodiment is TiO 2 Aerogel;

[0053] (3) airgel-alfalfa extract oil was mixed for 3 hours by ball milling;

[0054](4) 0.1 g of sodium borate and 10 g of water are mixed by magnetic stirring to form a transparent solution;

[0055] (5) The solutions obtained in step (3) and step (4) were mixed for 3 minutes, and left to stand for 2 hours to form an airgel-hydrogel composite drug carrier.

Embodiment 3

[0057] A preparation method of an airgel-hydrogel composite drug carrier, comprising the following steps:

[0058] (1) 10 g of polyvinyl alcohol and 90 g of water were magnetically stirred and mixed for 3 hours at a temperature of 95° C. to form a transparent solution;

[0059] (2) 1g airgel powder is mixed with 3g isopropyl palmitate, and mixed with the transparent solution obtained in step (1) to obtain airgel-borage oil mixture; the airgel powder used in this embodiment is Al 2 o 3 Aerogel;

[0060] (3) Airgel-isopropyl palmitate was mixed for 3 hours by ball milling;

[0061] (4) freezing the solution obtained in step (3) at minus 60° C. for 12 hours;

[0062] (5) melting the material obtained in step (4) at 25° C. for 12 hours;

[0063] (6) freezing the solution obtained in step (5) at minus 60° C. for 12 hours;

[0064] (7) The material obtained in step (6) was melted at 25° C. for 12 hours to obtain an airgel-hydrogel composite drug carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com