A wave-making cylinder for a mechanically rotating bubble generator, an environmentally friendly water treatment system

A bubble generator and treatment system technology, applied in sustainable biological treatment, water/sludge/sewage treatment, water aeration, etc., can solve the problems of easy generation of air belt, increase energy consumption, motor heating, etc., to reduce The effect of local temperature, improving overall life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

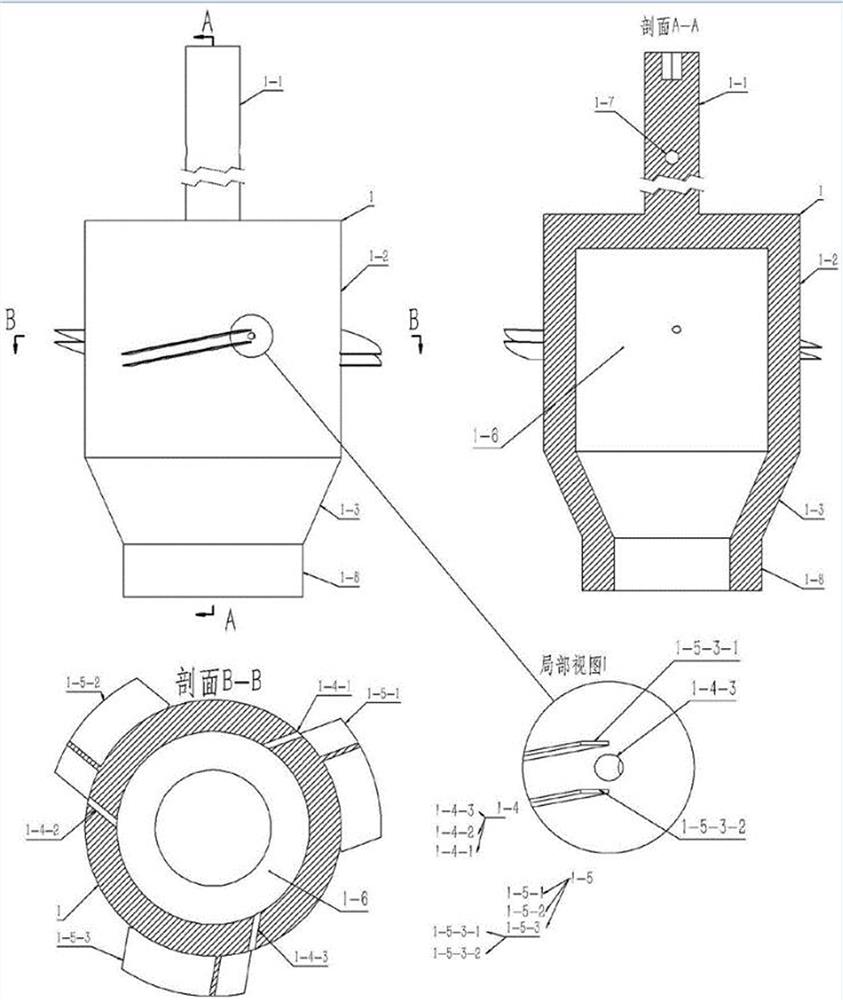

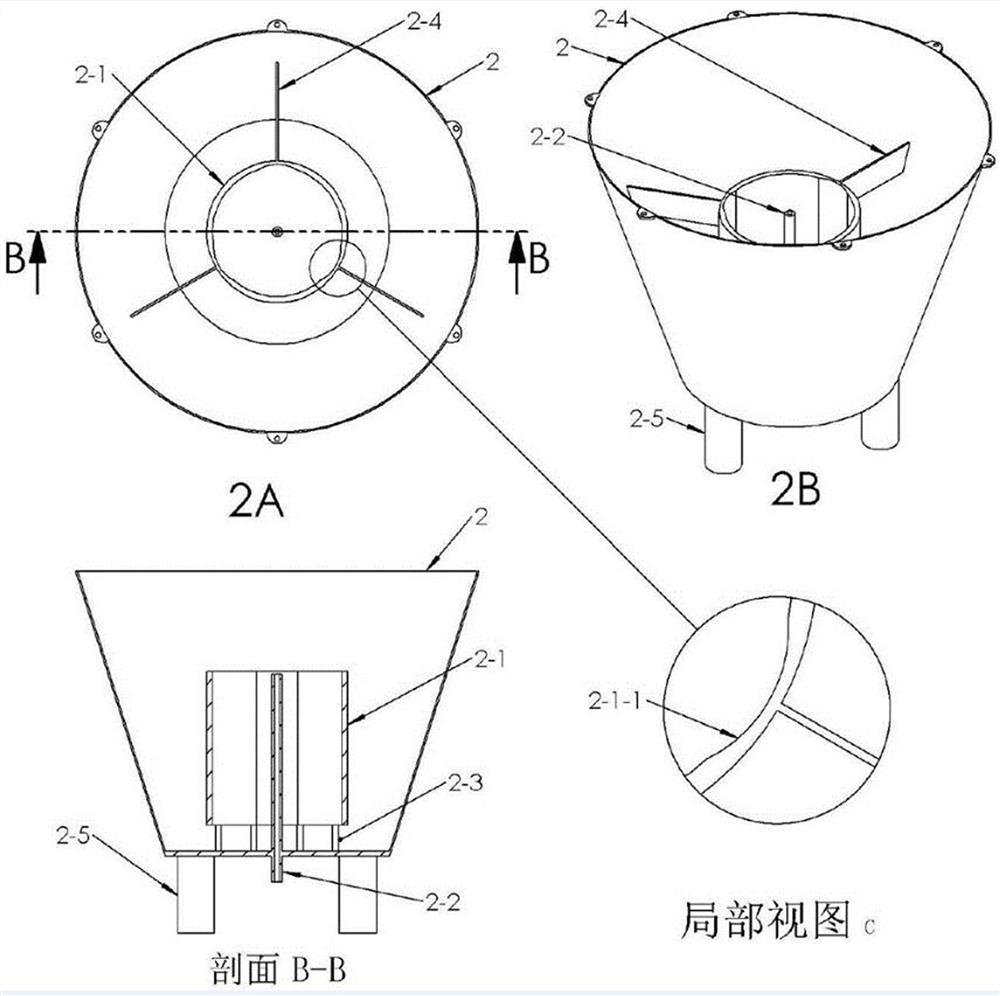

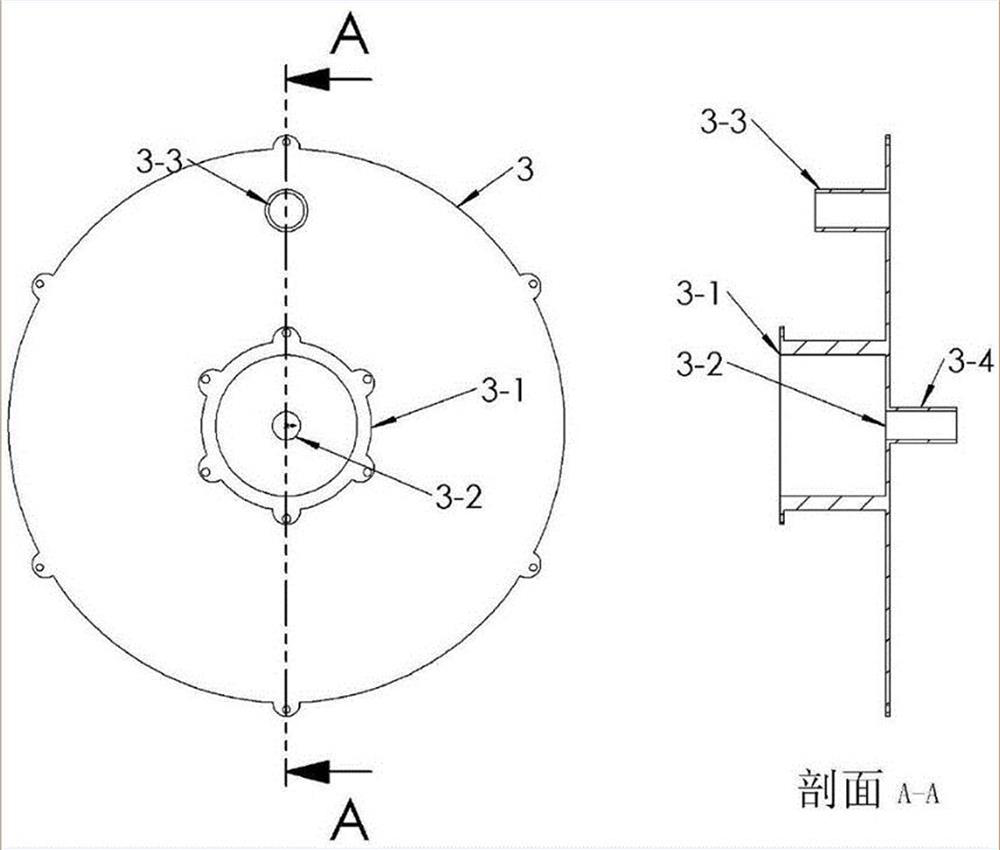

[0027] Embodiment 1, as Figure 1-7 , a mechanical rotary air bubble generator, characterized in that: comprising a rotor (1), a container (2), a cover (3), a bearing (4), a motor (5), and a rivet (6);

[0028] The rotor (1) includes a connection part (1-1), an inverted container (1-2), a waist opening (1-3), an air outlet hole (1-4), an air inlet opening (1-8), and a drive vane set (1-5);

[0029] In the rotor (1): the connection part (1-1) is cylindrical, and the connection part (1-1) has a connection hole (1-7), and the axis of the connection part (1-1) is aligned with the connection hole (1-7). ) axes perpendicularly intersect, and the upper end of the connecting part (1-1) has a motor connection structure;

[0030] In the rotor (1): the undercut container (1-2) is cylindrical, and the undercut container (1-2) has a cylindrical cavity (1-6), and the cylindrical cavity (1-6) and the undercut The containers (1-2) are coaxial, and the upper end of the inverted container (1...

Embodiment 2

[0050] Embodiment 2. On the basis of Embodiment 1, the rotor (1) is made of metal.

[0051] Embodiment 2. On the basis of Embodiment 1, the rotor (1) is made of organic material.

Embodiment 3

[0052] Embodiment 3. On the basis of Embodiment 1, the rotor (1) is a single integrated component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com