Chloroprene rubber sheath material used for cables and resistant to extreme cold and preparation method of chloroprene rubber sheath material

A neoprene sheath, extremely cold technology, applied in the field of extreme cold resistant neoprene sheath materials for cables, can solve the problems of affecting the service life, cracking of the cable sheath surface, poor flexibility, etc., to achieve the first step Ease of use, simple preparation method, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

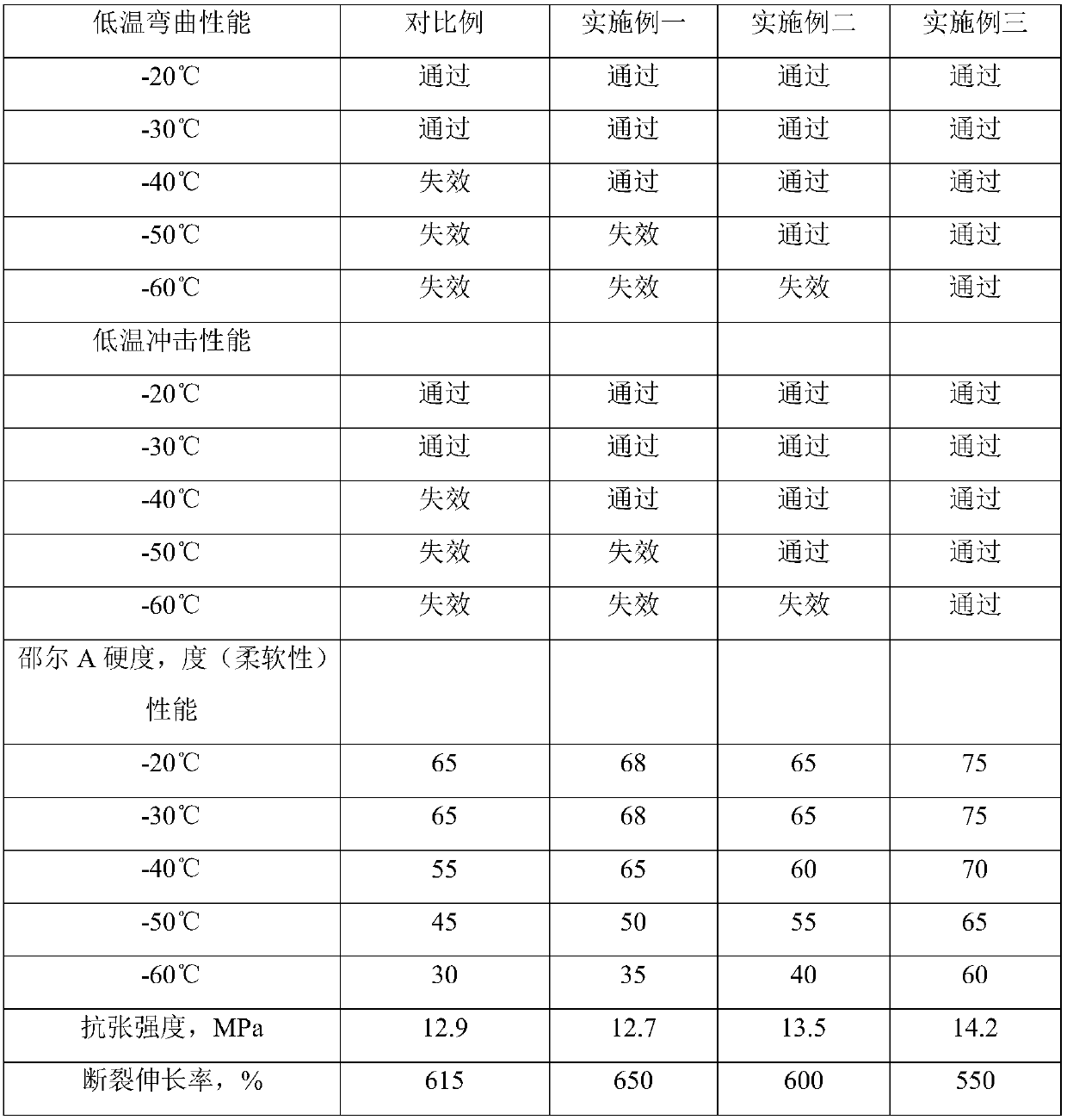

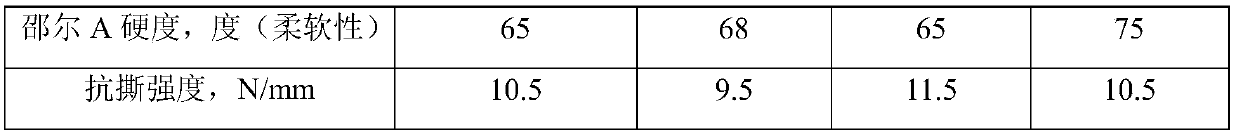

Examples

Embodiment 1

[0018] An extremely cold-resistant chloroprene rubber sheath material for cables. The components are 100 parts by weight of CRSN322 resin, 5 parts of magnesium oxide, 26 parts of N330 carbon black, 10 parts of SRF carbon black, and 100 parts of calcined clay , 20 parts of aluminum hydroxide, 4 parts of zinc oxide, 0.4 parts of vulcanizing agent DM, 5 parts of paraffin, 2 parts of stearic acid, 10 parts of plasticizer DOP, 10 parts of plasticizer DEP dioctyl ester, 2 parts of antioxidant RD, 1 part of silane coupling agent and 4 parts of release agent.

[0019] The preparation method of extremely cold-resistant neoprene sheath material for cables includes the following steps:

[0020] (1) Take 100 parts of CRSN322 resin, 5 parts of magnesium oxide, 26 parts of N330 carbon black, 10 parts of SRF carbon black, 100 parts of calcined clay, 20 parts of aluminum hydroxide, 4 parts of zinc oxide, vulcanizing agent DM 0.4 parts, 5 parts paraffin wax, 2 parts stearic acid, 10 parts plastici...

Embodiment 2

[0026] An extremely cold-resistant chloroprene rubber sheath material for cables. The components are 100 parts by weight of CRSN322 resin, 4 parts of magnesium oxide, 25 parts of N330 carbon black, 15 parts of SRF carbon black, and 100 parts of calcined clay , 25 parts of aluminum hydroxide, 4 parts of zinc oxide, 0.4 parts of vulcanizing agent DM, 5 parts of paraffin, 0.5 parts of stearic acid, 10 parts of plasticizer DOP, 10 parts of plasticizer DEP dioctyl ester, 2 parts of antioxidant ODA , 1 part of silane coupling agent, 5 parts of release agent.

[0027] The preparation method of extremely cold-resistant neoprene sheath material for cables includes the following steps:

[0028] (1) Take 100 parts of CRSN322 resin, 4 parts of magnesium oxide, 25 parts of N330 carbon black, 15 parts of SRF carbon black, 100 parts of calcined clay, 25 parts of aluminum hydroxide, 4 parts of zinc oxide, vulcanizing agent DM 0.4 parts, 5 parts of paraffin wax, 0.5 parts of stearic acid, 10 parts...

Embodiment 3

[0034] An extremely cold-resistant chloroprene rubber sheath material for cables. The components are 100 parts by weight of CRSN322 resin, 4 parts of magnesium oxide, 25 parts of N330 carbon black, 15 parts of SRF carbon black, and 100 parts of calcined clay , 25 parts of aluminum hydroxide, 4 parts of zinc oxide, 1.4 parts of vulcanization accelerator, 0.4 parts of vulcanizing agent DM, 5 parts of paraffin wax, 0.5 parts of stearic acid, 15 parts of plasticizer DOP, 15 parts of plasticizer DEP dioctyl , 2 parts of antioxidant ODA, 1 part of silane coupling agent, 5 parts of release agent.

[0035] The preparation method of extremely cold-resistant neoprene sheath material for cables includes the following steps:

[0036] (1) Take 100 parts of CRSN322 resin, 4 parts of magnesium oxide, 25 parts of N330 carbon black, 15 parts of SRF carbon black, 100 parts of calcined clay, 25 parts of aluminum hydroxide, 4 parts of zinc oxide, vulcanization accelerator 1.4 parts, vulcanizing agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com