Polycyclic aromatic hydrocarbon degradation agent and preparation method

A technology of polycyclic aromatic hydrocarbons and degradation agents, applied in the field of polluted soil, can solve the problems of high cost, large dosage, and difficulty in guaranteeing the oxidation effect, and achieve the effect of reducing the pollution concentration and improving the oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: A PAH-contaminated site was repaired with a composite oxidant, using an in-situ ex-situ method to mix the composite oxidant and soil through a mixer. The composite oxidant was calculated by weight, and the component A was 70 kg, and the component B was 30 kg. 21kg of sodium hypochlorite and 49kg of calcium hypochlorite in component A; 19.5kg of sodium persulfate, 7.5kg of potassium ferrate and 3kg of sodium hydroxide in weight percentage of each component in component B.

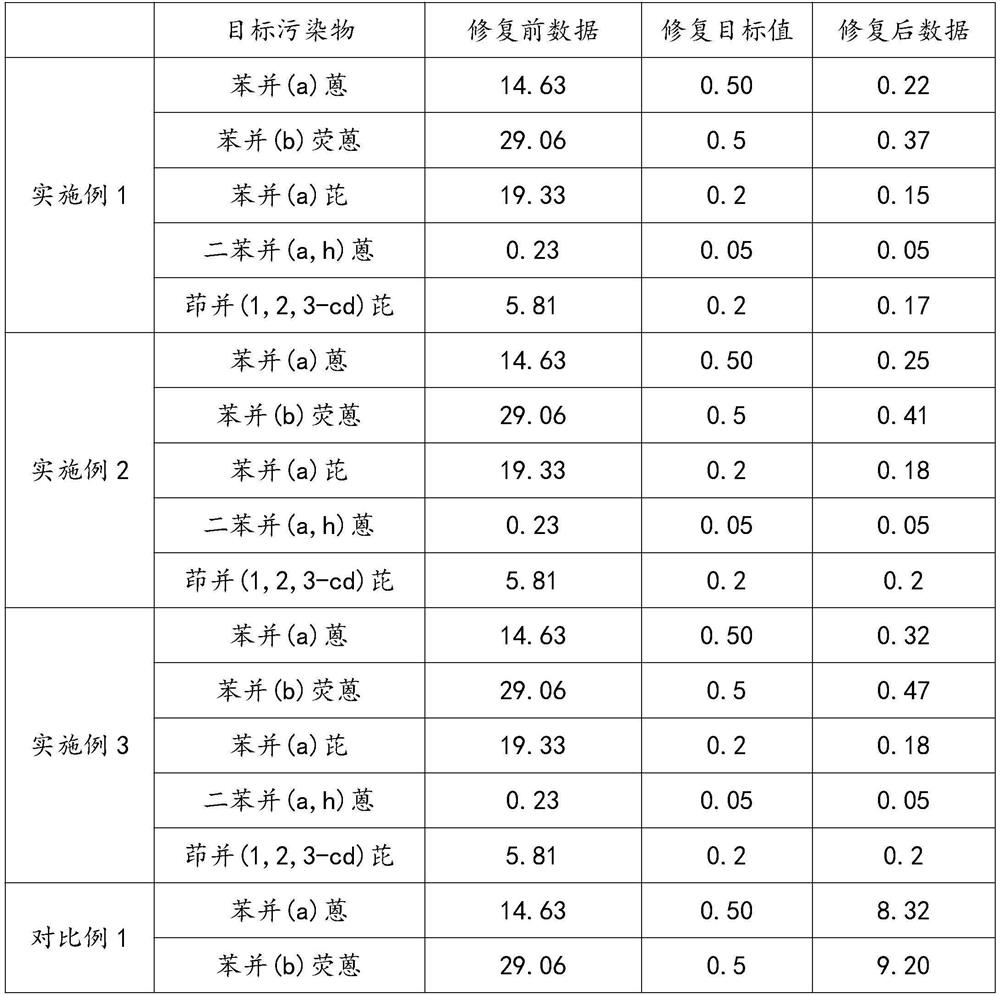

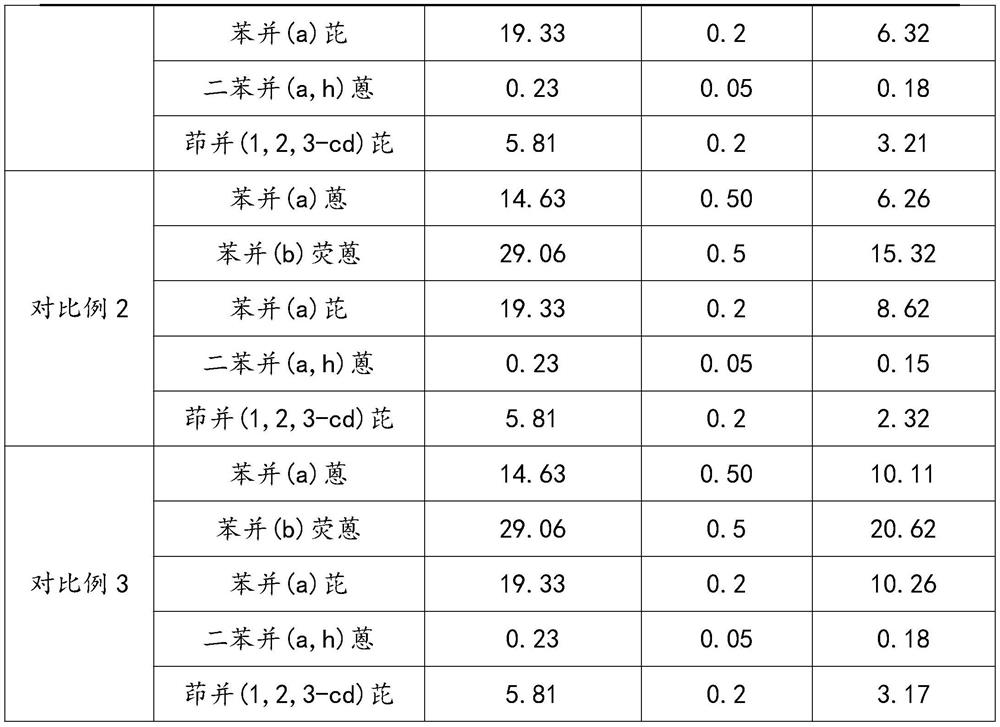

[0015] Prepare component A as a 3% by weight aqueous solution and store separately, and prepare component B as a 2% by weight aqueous solution as required and store separately. When in use, add and mix it in the mixer on site, make it fully mixed with the contaminated soil, and keep it stable for 20 days. After use, the typical polycyclic aromatic hydrocarbons in the contaminated soil decreased significantly. The comparison before and after remediation of five typical pollutants is shown i...

Embodiment 2

[0016] Example 2: A polycyclic aromatic hydrocarbon contaminated site is rehabilitated using a composite oxidant, using an in-situ ex-situ method, mixing the composite oxidant and soil through a mixer, the composite oxidant is by weight, A component 58kg; B component 42kg; The A component includes: calcium hypochlorite 10.44kg, calcium hypochlorite 47.56kg; B component includes: sodium persulfate 23.52kg, potassium ferrate 10.5kg, sodium hydroxide 7.14kg. The preparation method is the same as in Example 1, and the comparison before and after remediation of five typical pollutants is shown in Table 1.

Embodiment 3

[0017] Embodiment 3: a certain polycyclic aromatic hydrocarbon contaminated site is rehabilitated using a composite oxidant, adopting an in-situ ex-situ method, mixing the composite oxidant and soil by a mixer, the composite oxidant is by weight, A component 86kg; B component 14kg; wherein The A component includes: calcium hypochlorite 39.56kg, calcium hypochlorite 46.44kg; B component includes: sodium persulfate 10.64kg, potassium ferrate 2.66kg, sodium hydroxide 0.7kg. The preparation method is the same as in Example 1, and the comparison before and after remediation of five typical pollutants is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com