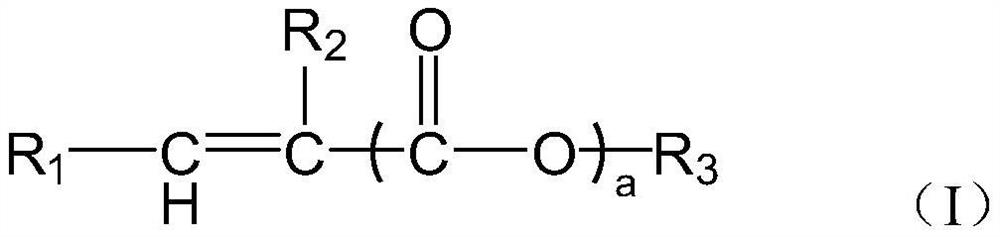

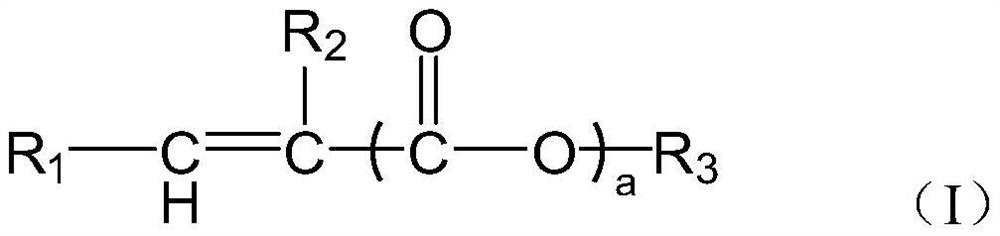

Gasoline engine lubricating oil composition and preparation method thereof

A kind of lubricating oil composition, polymerization reaction technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of vehicle burning, unqualified low temperature pumping performance, etc., and achieve the effect of excellent low temperature performance and excellent antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

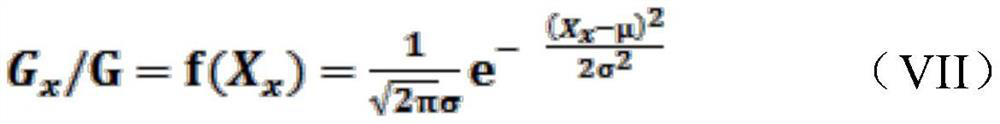

Method used

Image

Examples

Embodiment

[0099] The following examples will be used to illustrate the present invention in further detail, but the present invention is not limited to these examples.

[0100] In the following examples and comparative examples, the respective contents of the copolymer and the diluent oil and the contents of each monomer in the copolymer are calculated according to the feed amount.

[0101] In the context of the present invention, including in the following Examples and Comparative Examples, each measurement method and calculation method were performed as follows.

[0102] 1. Gel permeation chromatography (GPC) resolution method

[0103] Operating instrument: Model 1515 gel permeation chromatography produced by Waters Corporation of the United States. The detector is a Waters 2414 differential refractive index detector. The solvent used to configure the standard is chromatographically pure tetrahydrofuran produced by Acros. The chromatographic column is provided by Waters Company, wh...

Embodiment A

[0136] Under the protection of nitrogen, add 113kg of diluent oil (purchased from Ssangyong Company, the brand is 100N, the same below) into the reaction kettle equipped with mechanical stirring, heat to 83-91°C, and 270kg of the first monomer (decyl methacrylate ester / lauryl methacrylate / tetradecyl methacrylate / hexadecyl methacrylate / octadecyl methacrylate mixture, where C 10 = 61%, C 12 = 20%, C 14 = 12%, C 16 = 5%, C 18 =2%, X=11.1), the mixture A of 1.35kg benzoyl peroxide and 1.08kg dodecyl mercaptan is added dropwise in the reactor, simultaneously with the second monomer of 150kg (tetradecyl methacrylate ester / cetyl methacrylate / octadecyl methacrylate / eicosyl methacrylate mixture, where C 14 = 27% by weight, C 16 = 42%, C 18 = 24%, C 20 =7% by weight, X=16.0), the mixture B of 0.75kg benzoyl peroxide and 0.6kg dodecylmercaptan was added dropwise in the reaction kettle. At the initial moment of dropping, the ratio A / B of the dropping amount (kg / hour) of mixture A ...

Embodiment B

[0140] Under the protection of nitrogen, add 113kg of diluent oil (purchased from Ssangyong Company, the brand is 100N, the same below) into the reaction kettle equipped with mechanical stirring, heat to 83-91°C, and 50kg of the first monomer (methacrylic acid hexyl ester / octyl methacrylate / decyl methacrylate mixture, where C 6 = 71%, C 8 = 21%, C 10 =8%, X=6.6), the mixture A of 0.32kg benzoyl peroxide and 0.21kg dodecyl mercaptan is added dropwise in the reactor, simultaneously with the second monomer of 370kg (dodecyl methacrylate Esters / myristyl methacrylate / hexadecyl methacrylate mixture, where C 12 = 55% by weight, C 14 = 17% by weight, C 16 =28% by weight, X=13.3), the mixture B of 1.8kg benzoyl peroxide and 1.5kg dodecylmercaptan was added dropwise in the reaction kettle. At the initial moment of dropping, the ratio A / B of the dropping amount (kg / hour) of mixture A and the dropping amount (kg / hour) of mixture B is 7:1, and the sum of the two is 12kg / hour, then A / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com