Microbial cell factory based on photoinduced dielectrophoresis technology and application thereof

A light-induced dielectrophoresis and microbial cell technology, applied in the field of fermentation, can solve problems such as complicated procedures, long parameter selection time, and difficulty in obtaining optimal parameters, so as to improve fermentation efficiency, shorten optimization cycle, and uniform excellent strains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

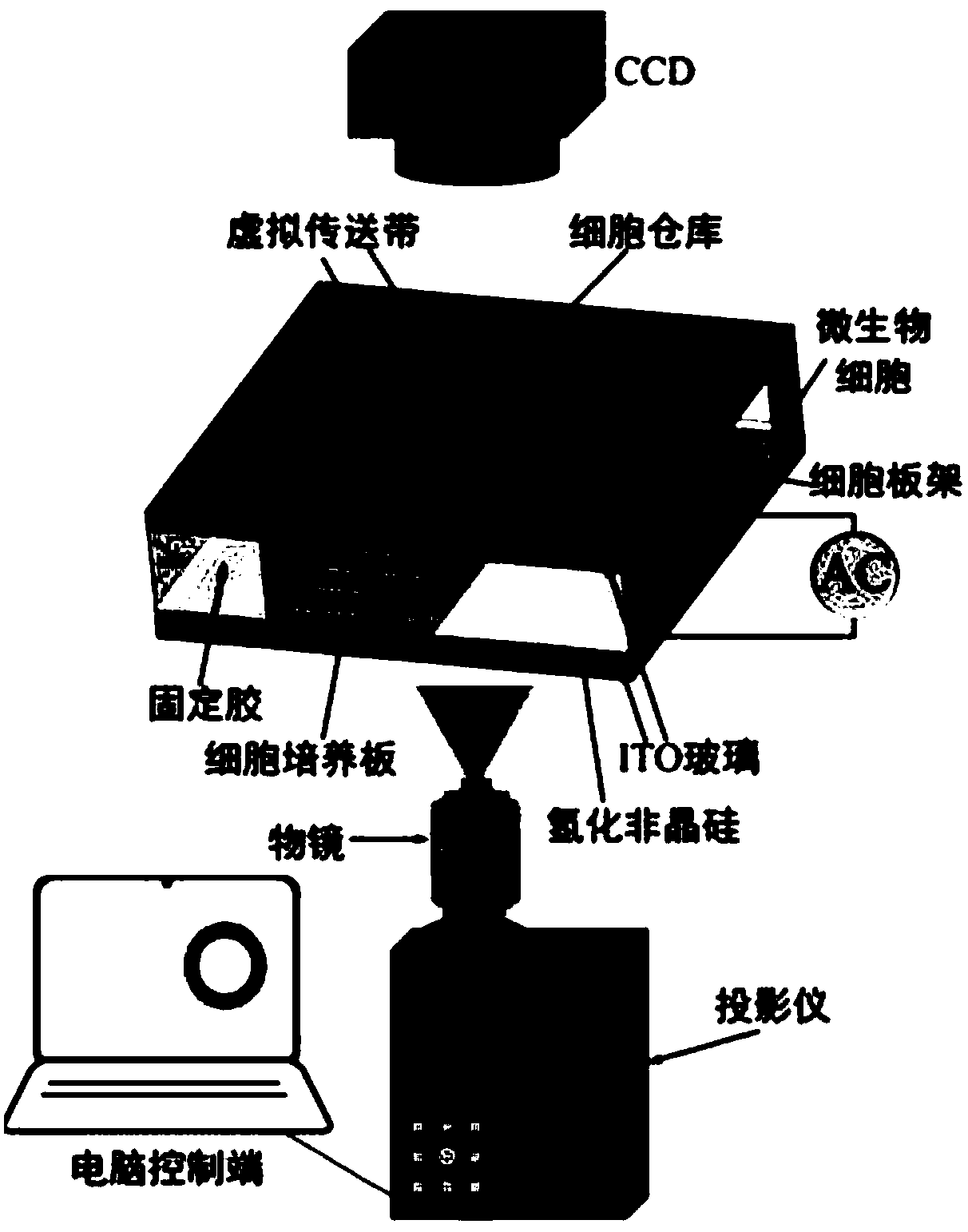

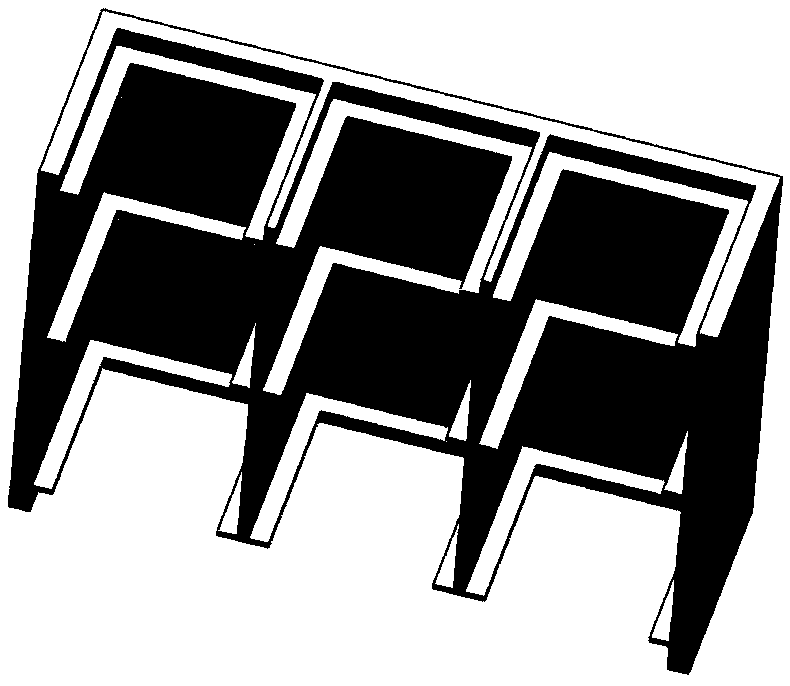

[0031] The principle of equipment for constructing microbial cell factories based on light-induced dielectrophoresis technology is as follows: figure 1 shown. The equipment mainly includes four parts: observation part, ITO (indium tin oxide) sandwich mechanism part, microbial cell factory part and light operation part.

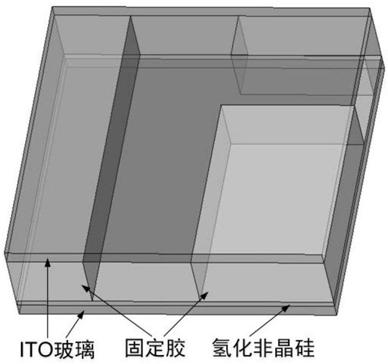

[0032]The observation part is mainly composed of a high-definition CCD and related software, which is used to observe or record the process of cell factory establishment, microbiological cell screening, and cell plate rack operation. The ITO sandwich mechanism mainly consists of two layers of ITO glass and an intermediate layer. The upper surface of the lower ITO glass is coated with a layer of hydrogenated amorphous silicon with a thickness of about 0.5-1 μm. The intermediate layer is fixed by a fixing glue. Spaces such as cell factories and cell operations are isolated. ITO glass is coated with a layer of ITO film with a thickness of about 180nm on the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com