Novel evaporation metal mask plate and evaporation device

A metal mask, metal mask technology, applied in vacuum evaporation coating, metal material coating process, sputtering and other directions, can solve the problem that the mask cannot be closely attached to the substrate, and the mask and the silicon wafer are displaced. and other problems, to achieve the effect of eliminating shadow effect, avoiding movement dislocation, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

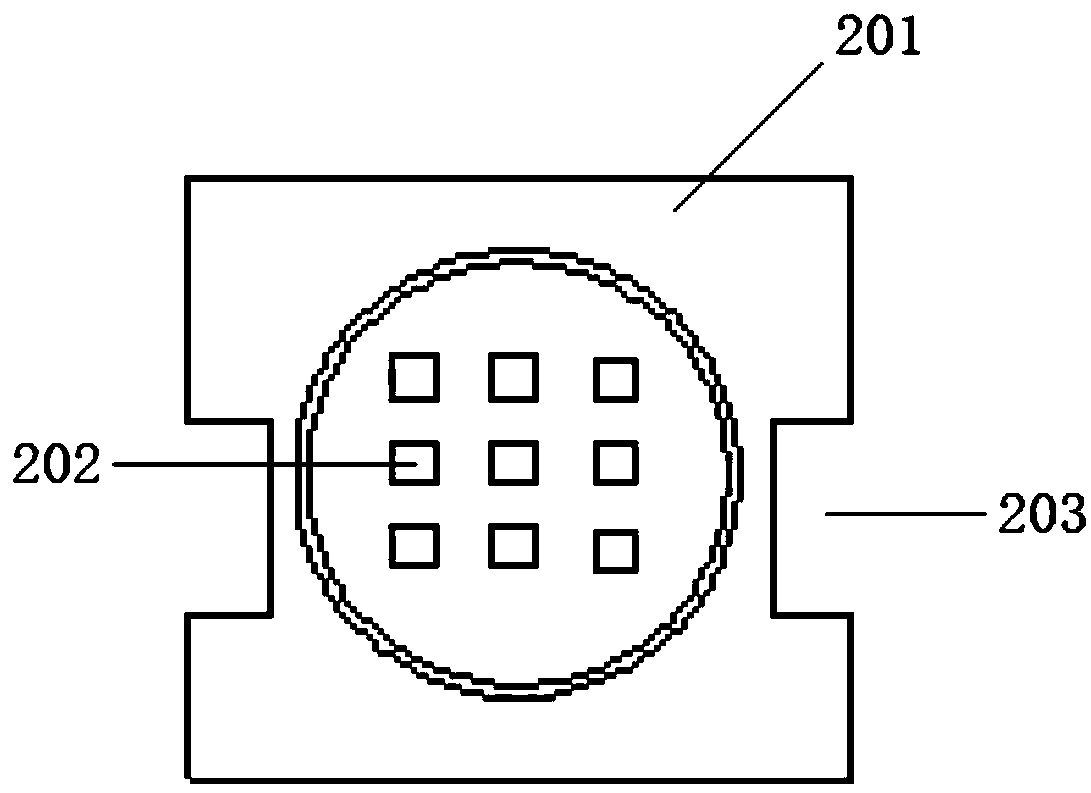

[0024] Such as figure 1 , image 3 and Figure 4 As shown, a new metal mask for evaporation of the present invention includes a mask body 201, a circular groove 1 is opened on the mask body 201, and several In the opening 202 of the diffusion material, the two sides of the mask body 201 are provided with slots 203 for installation; the cross section of the opening 202 is trapezoidal, which is beneficial for the material to diffuse to the silicon wafer 3 through the metal mask 2, The thickness of the opening is 2-3mm. In order to prevent deformation of the mask during pressing, a reinforcing rib 204 is fixed on the back of the mask body 201 .

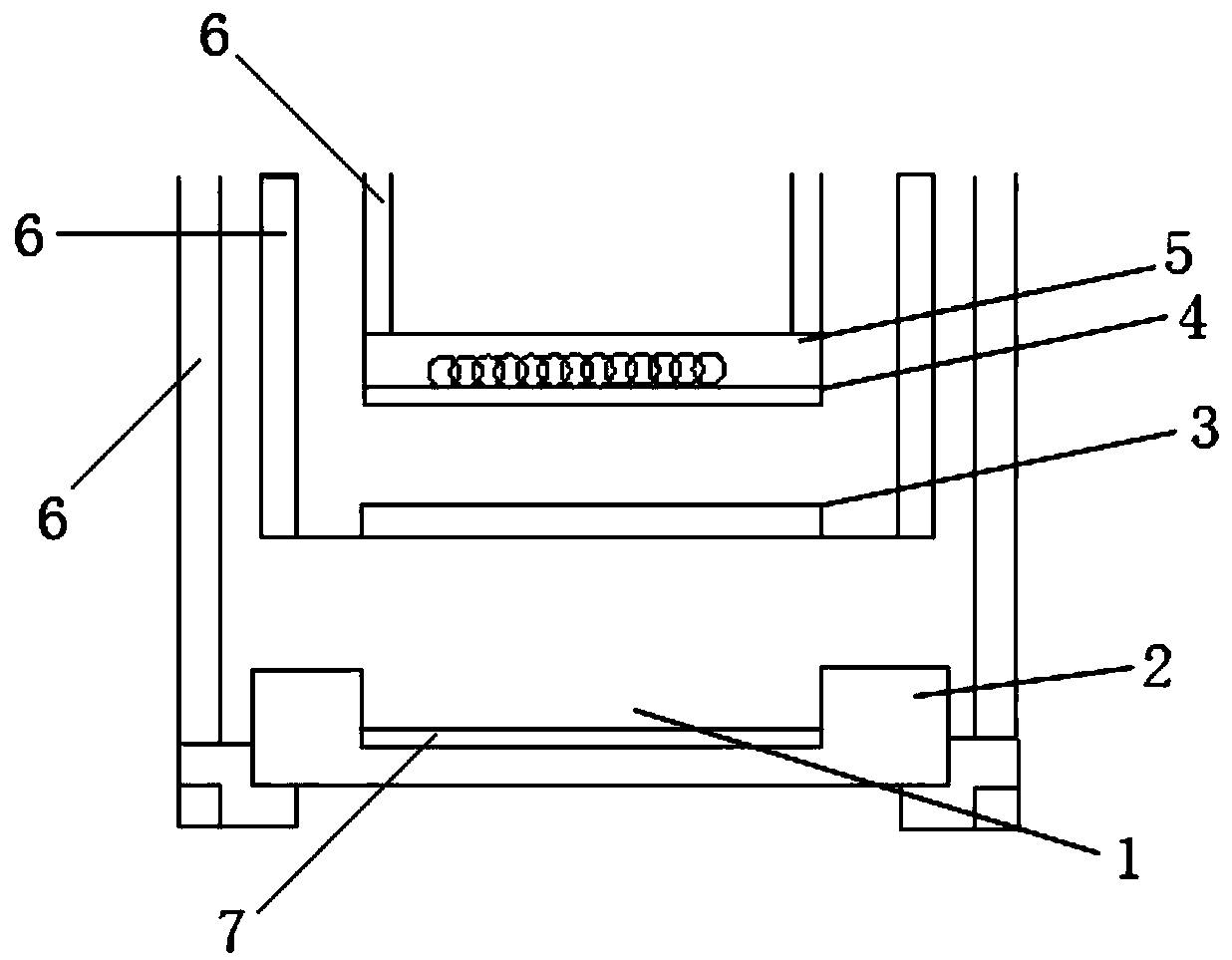

[0025] Such as figure 2 As shown, the present invention also includes a novel vapor deposition device, including the above-mentioned metal mask 2, the metal mask 2 is arranged on the base, and lifting rods 6 are fixed on both sides of the base; A support for placing the silicon wafer 3 and a clamp for pressing the silicon wafer 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com