A loom electronic take-up control method

A control method and technology of electronic rolling, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as driving marks, achieve the effects of reducing tolerance manufacturing requirements, eliminating gear gaps, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

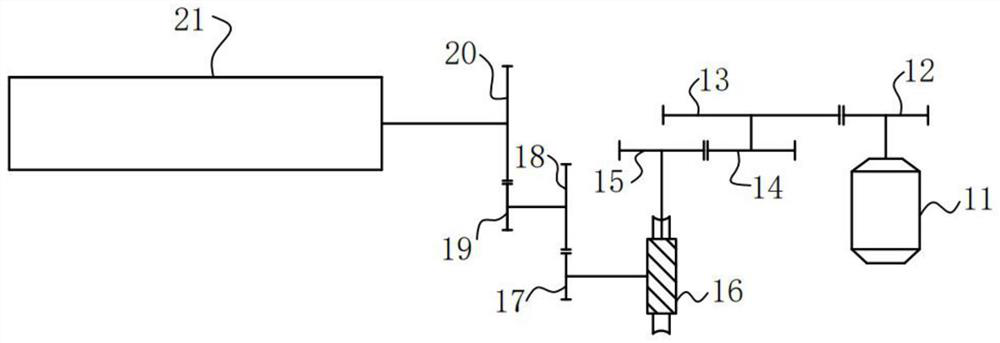

[0018]Such asfigure 1 As shown, there is inevitably a gap in the meshing of each gear. Through the amplification of the multi-stage transmission, the gap to the winding roller will be very large.

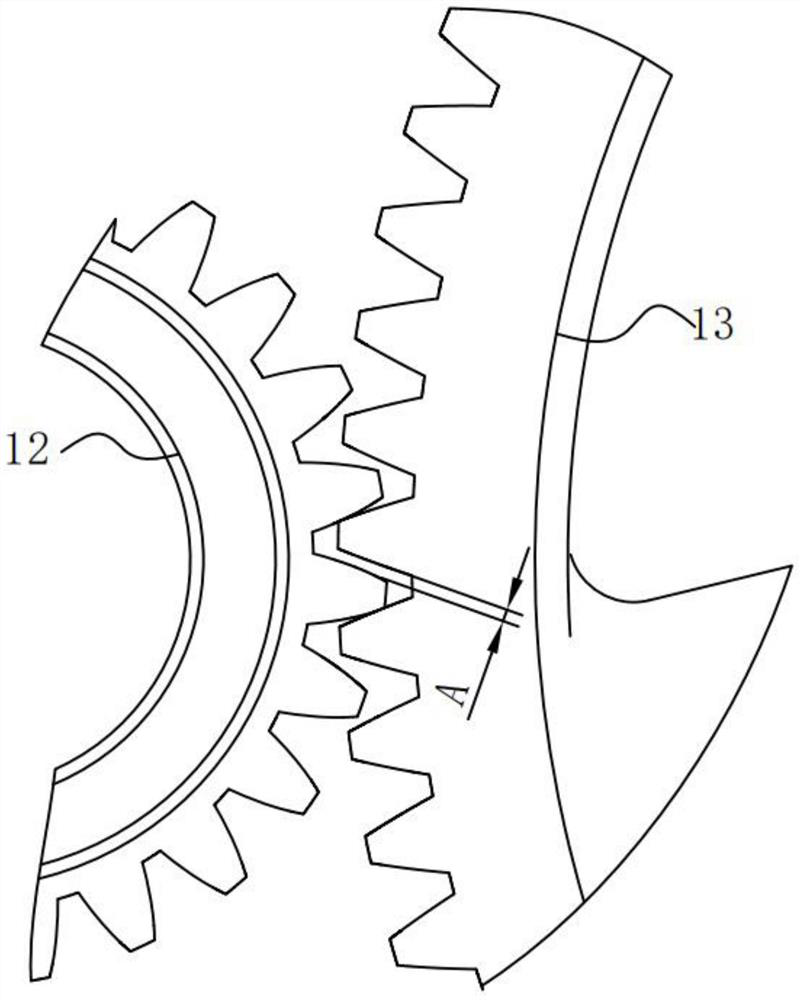

[0019]Such asfigure 2As shown, in this control method, when the rotation direction of the loom changes, the servo motor first adopts a torque control method to control the torque so that the first gear 12 connected to the servo motor is close to the second gear 13 in the opposite direction of the previous movement direction to eliminate the gear gap After A, the servo motor switches to position control mode. The operation of the loom can only be divided into express (only forward rotation), slow (inching forward and reverse rotation), and slow weft insertion (only forward rotation). When the loom stops, it will brake first and then automatically reverse to the positioning angle to stop. under. The rotation direction changes of the loom include: reversal of fast parking positioning, forward-r...

Embodiment 2

[0022]On the basis of traditional pulse + direction (also can be forward and reverse pulse, AB phase pulse and other well-known position control methods), alarm, alarm reset, S-ON, 24V, 0V, the main control computer adds position-torque switching signal and Torque limit signal. The position-torque switching signal is torque control when OFF, and position control when ON; the torque limit signal is to set a maximum torque limit value in the range of -100%-+100% torque, which can be used by the host computer -10V--+10V voltage signal control is realized, and the set value is determined according to the actual weaving situation.

[0023]When the loom is running and stopped, the main shaft is braked by the brake disc, and then slowly reverses to the positioning stop angle to stop. At this time, the take-up servo motor is position controlled and the spindle rotates to the brake stop position, and then the main control computer gives a switching signal OFF, the servo drive switches to torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com