Method for preparing silver-based inorganic antibacterial material

An inorganic antibacterial material and silver-based technology, which is applied in the field of preparation of silver-based inorganic antibacterial materials, can solve the problems of large loss of nano-silver, decreased antibacterial effect of fabrics, and reduced antibacterial effect, so as to improve antibacterial effect, avoid loss of nano-silver, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The knitted fabric was washed with ionized water for 10 minutes, dried with a dryer, and then sealed and placed.

[0026] 1) Take a quantitative concentration of 0.3mol / L potassium persulfate solution, use sodium hydroxide to adjust the pH until the pH value is 9, the initiator configuration is completed, and the knitted fabric is put into the initiator, the bath ratio is 1:30, Then the temperature is raised to 70 degrees Celsius, and the dipping treatment is carried out at this temperature for 30 minutes.

[0027] 2) The grafting reaction of the knitted fabric is more efficient after being impregnated with the initiator. A certain amount of 0.5 mol / L methacrylamide is added to the impregnated solution of the knitted fabric, and then the grafting reaction is carried out at 70 degrees Celsius for 1.5 hours.

[0028] 3) After the grafting reaction is completed, the knitted fabric is taken out, fully washed with water, and then extracted with an acetone Soxhlet extractor f...

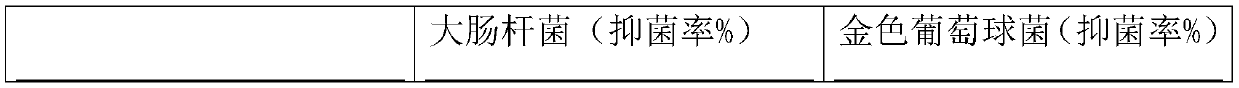

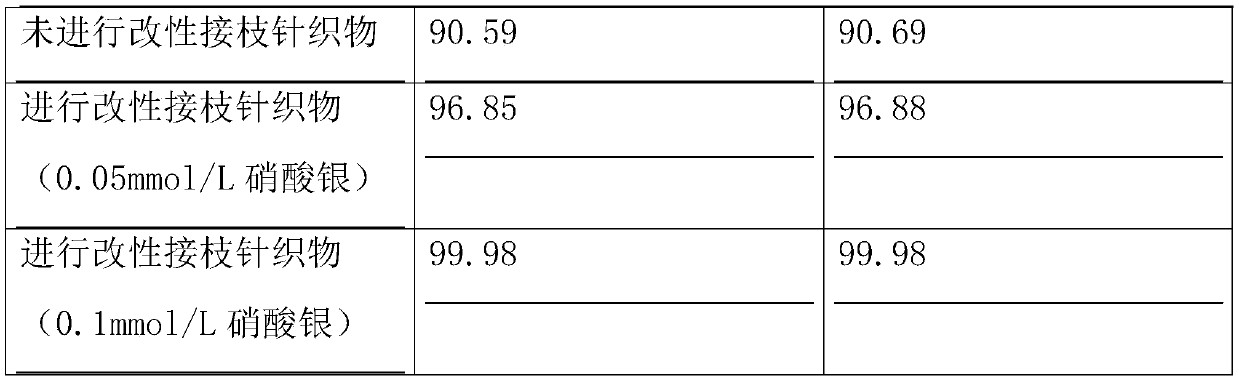

Embodiment 2

[0032] 1) Take a quantitative concentration of 0.3mol / L potassium persulfate solution, use sodium hydroxide to adjust the pH until the pH value is 9, the initiator configuration is completed, and the knitted fabric is put into the initiator, the bath ratio is 1:30, Then the temperature is raised to 70 degrees Celsius, and the dipping treatment is carried out at this temperature for 30 minutes.

[0033] 2) The grafting reaction of the knitted fabric is more efficient after being impregnated with the initiator. A certain amount of 0.5 mol / L methacrylamide is added to the impregnated solution of the knitted fabric, and then the grafting reaction is carried out at 70 degrees Celsius for 1.5 hours.

[0034] 3) After the grafting reaction is completed, the knitted fabric is taken out, fully washed with water, and then extracted with an acetone Soxhlet extractor for 8 hours to remove the polymethacrylamide homopolymer on the surface of the grafted knitted fabric.

[0035] 4) Immerse ...

Embodiment 3

[0039] 1) Take a quantitative concentration of 0.3mol / L potassium persulfate solution, use sodium hydroxide to adjust the pH until the pH value is 9, the initiator configuration is completed, and the knitted fabric is put into the initiator, the bath ratio is 1:30, Then the temperature is raised to 70 degrees Celsius, and the dipping treatment is carried out at this temperature for 30 minutes.

[0040] 2) The grafting reaction of the knitted fabric is more efficient after being impregnated with the initiator. A certain amount of 0.5 mol / L methacrylamide is added to the impregnated solution of the knitted fabric, and then the grafting reaction is carried out at 70 degrees Celsius for 1.5 hours.

[0041] 3) After the grafting reaction is completed, the knitted fabric is taken out, fully washed with water, and then extracted with an acetone Soxhlet extractor for 8 hours to remove the polymethacrylamide homopolymer on the surface of the grafted knitted fabric.

[0042] 4) Immerse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com