Draining self-adjusting rotary air heater and adjusting method thereof

A technology of automatic adjustment and adjustment method, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problem of increasing the primary and secondary air side resistance of the boiler, the power consumption of the primary fan, the blower, and the steam consumption of the heater. and temperature changes, heat exchange elements cannot be moved, etc., to achieve the effect of high thermal energy utilization, saving plant electricity, and improving heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

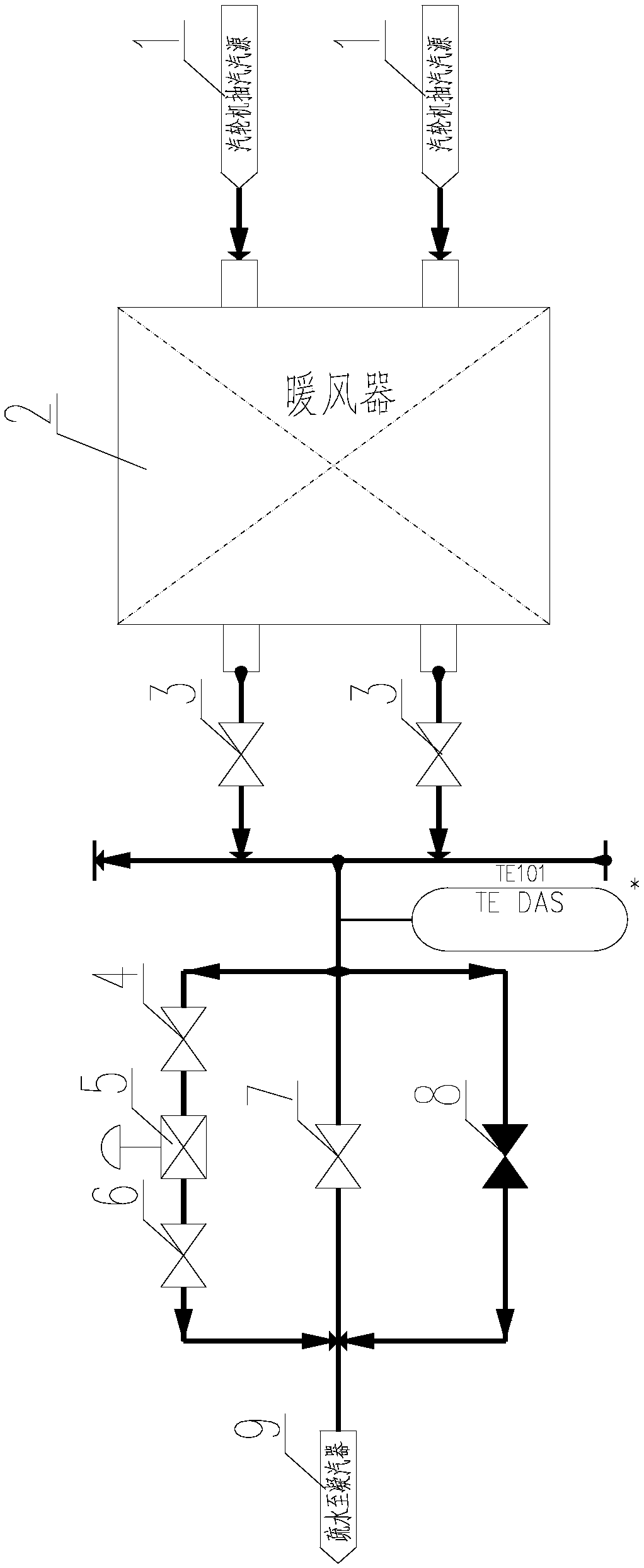

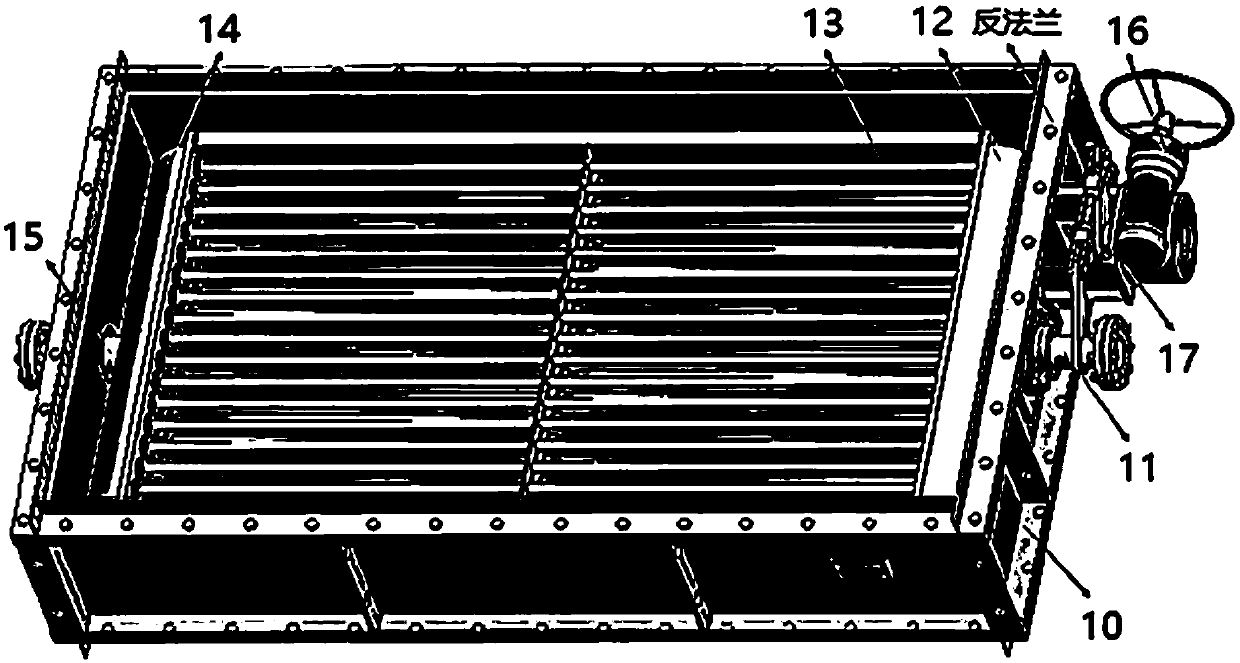

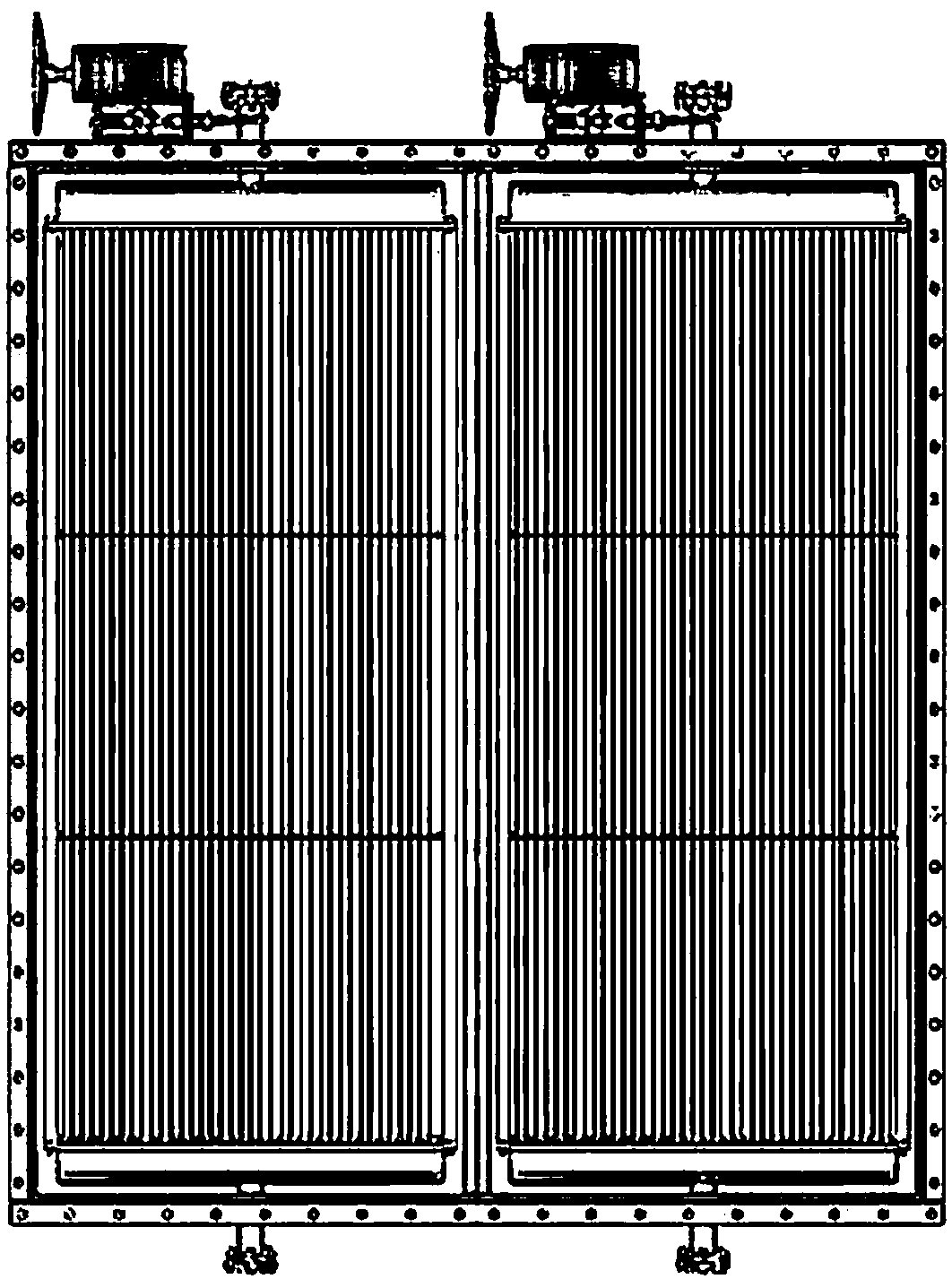

[0020] see Figure 1-2 , the rotary air heater with automatic adjustment of the hydrophobic side of the present invention structurally includes a housing 10, a steam inlet pipe 11, a steam inlet pipe box 12, a finned tube 13, a drain pipe box 14, a drain pipe 15, and a reducer 16 And the link mechanism 17.

[0021] The heat exchange element of the air heater is arranged in the housing 10, one end of the heat exchange element of the air heater is connected to the steam inlet pipe 11, and the other end is connected to the drain pipe 15; The heat exchange element of the fan rotates between 0° and 90°. There are station pointers and dials on the surface of the reducer 16. When the station pointer points to 0° of the dial, it means that the heater is in working condition. When the pointer points to 90° of the dial, it means the heater is not working.

[0022] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com