Annular fixed bed combustion furnace applied to powder materials

A technology of annular furnace and fixed bed, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of not meeting quality requirements, narrow application surface, complex furnace structure, etc., achieving simple structure, long service life, The effect of large output adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

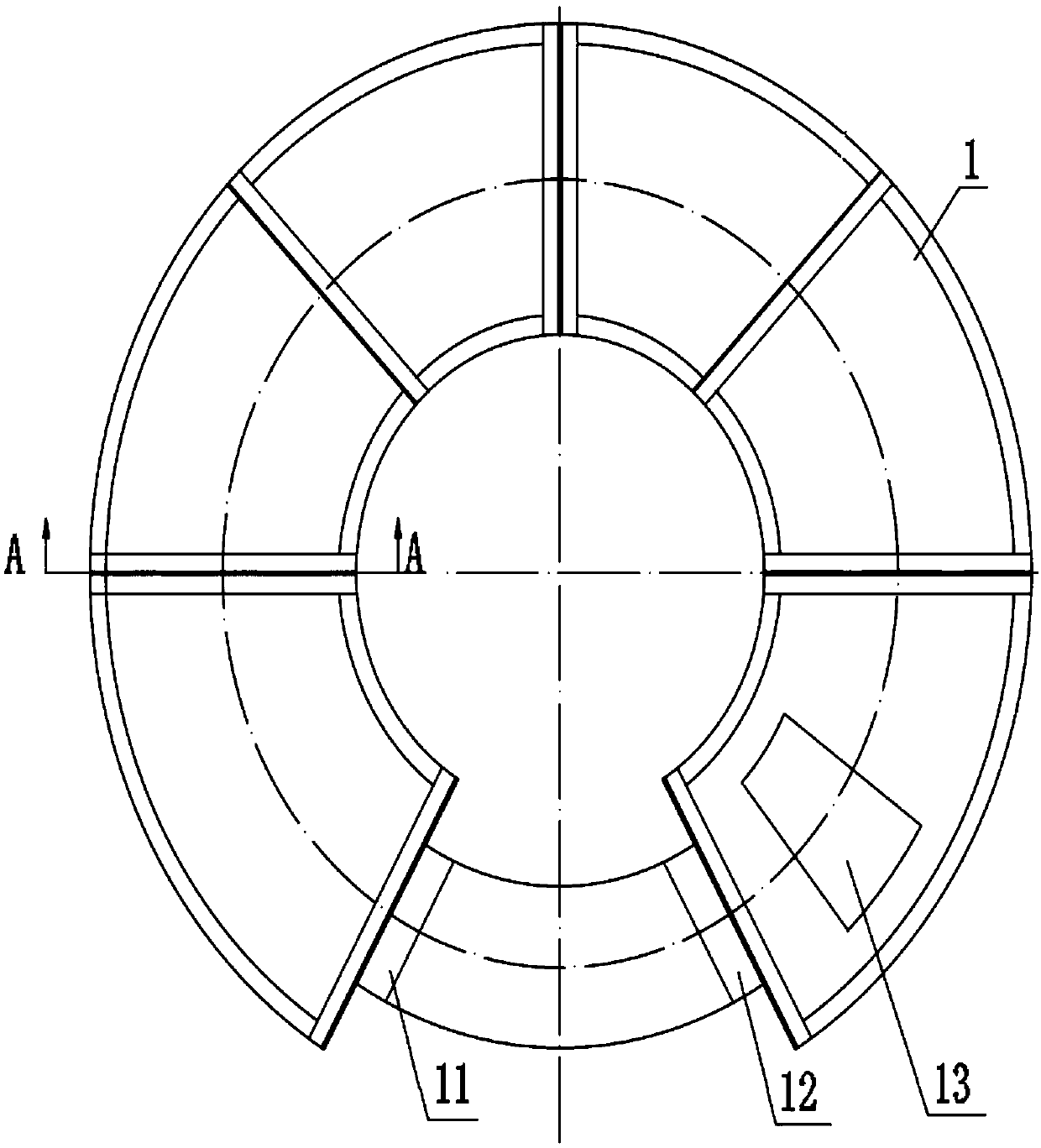

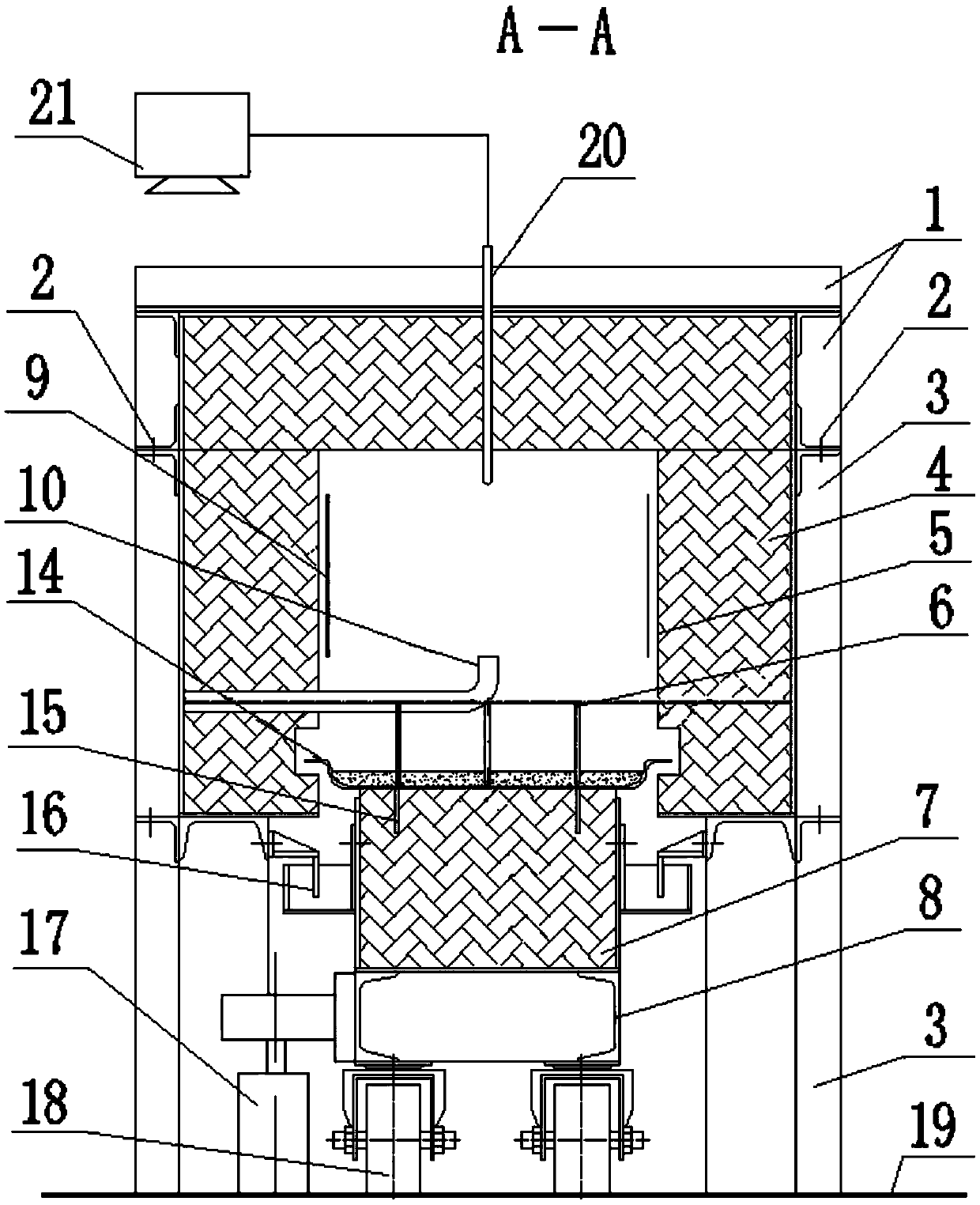

[0024] Embodiment 1: The present invention provides a kind of annular fixed-bed combustion furnace that is applied to powder material, and its structure is as follows figure 1 , 2 shown. figure 1 For the top view of the combustion furnace, from figure 1 It can be seen that the overall structure of the combustion furnace of the present invention is an annular furnace of continuous production type. On the figure, it can be seen that the annular combustion furnace is provided with an annular furnace cover, and the body of furnace and the bottom of the furnace under the furnace cover are also annular. figure 1 There is a material inlet on the left side of the middle combustion furnace, and a distributing machine 11 is provided, and there is an outlet on the right side, and a discharge machine 12 is provided. There is a smoke exhaust device 13 on the right side of the discharge machine, and the smoke generated by the material combustion is produced. Smoke exhaust device exhaust. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com