Extracting device and method of microplastics in soil

An extraction device and technology for microplastics, which are used in chemical instruments and methods, preparation of samples for testing, solid separation, etc., can solve the problems of in-depth development of pollution research, restricting microplastics, etc., to shorten the separation time, easy to operate, and save money. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

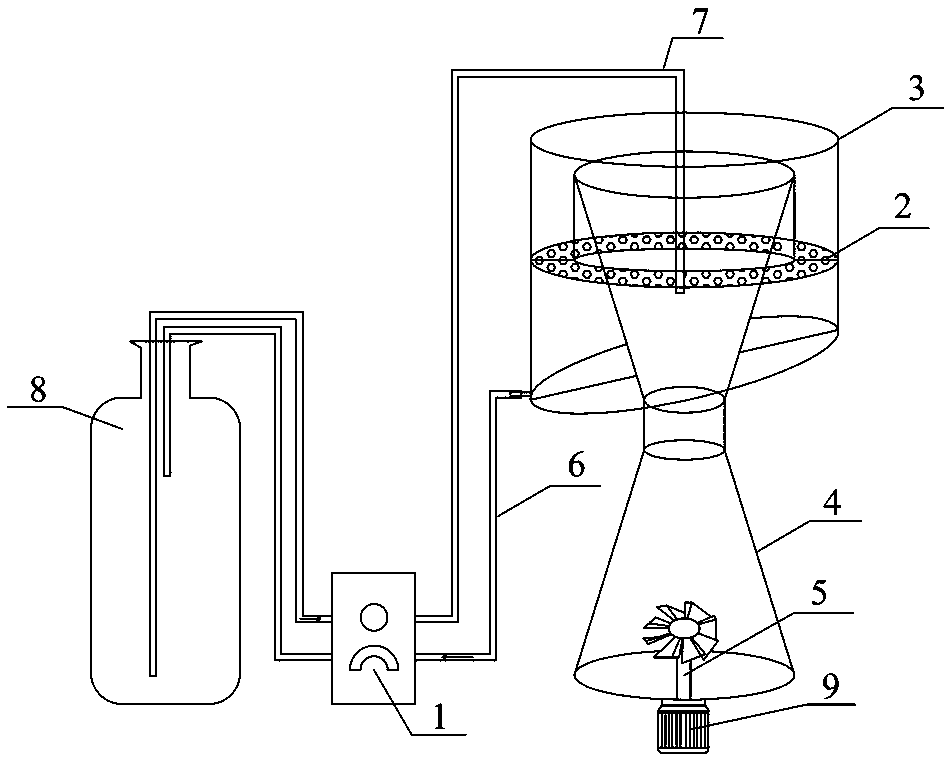

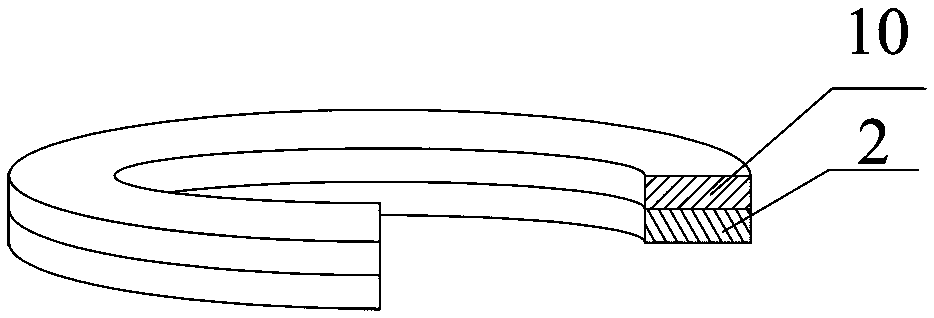

[0036] like Figure 1 to Figure 3As shown, an extraction device for microplastics in soil includes a separation tank 4, a liquid storage tank 8 and a liquid return tank 3, and a liquid inlet pipe 7 is arranged between the liquid storage tank 8 and the separation tank 4, and the liquid return A liquid outlet pipe 6 is provided between the pool 3 and the liquid storage tank 8, and a peristaltic pump 1 is provided on the liquid inlet pipe 7 and the liquid outlet pipe 6. The peristaltic pump 1 is a multi-channel peristaltic pump 1, and the separation pool 4 and the liquid return pool A layer of filter assembly is arranged between 3, and the filter assembly includes a ring screen 2 and a filter membrane 10, and the filter membrane 10 is arranged on the ring screen 2; The bottom of the separation tank 4 is provided with a stirrer 5 to stir The device 5 is connected to the motor 9 . Described separation pond 4 comprises upper round table and lower round table, and the height of desc...

Embodiment 2

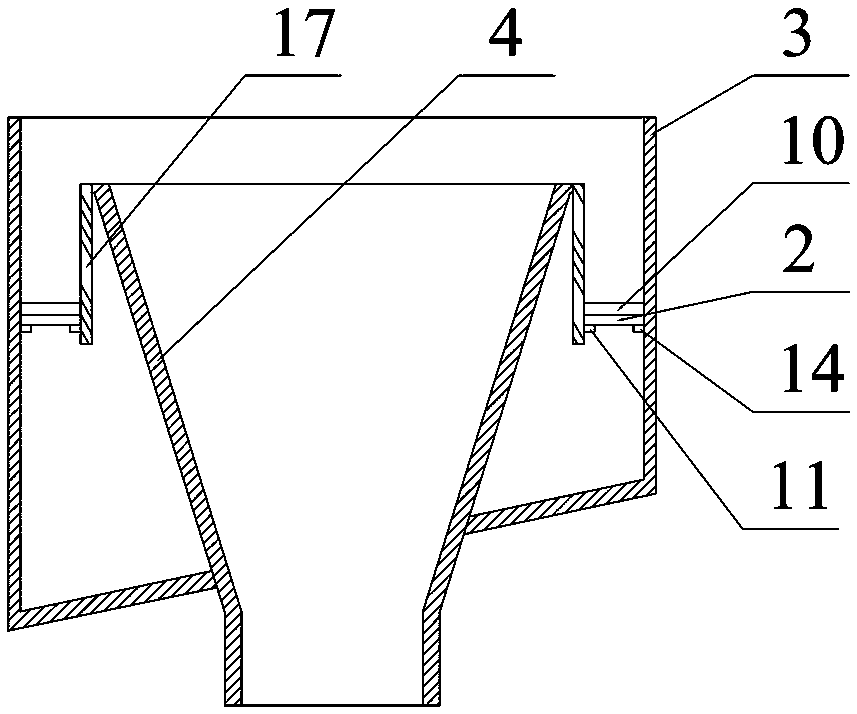

[0040] like figure 1 , Figure 4 and Figure 5 As shown, it is basically the same as Example 1, except that the angle between the bottom surface of the liquid return tank 3 and the horizontal plane is 45°, the filter assembly is two layers, and the two layers of filter assemblies are distributed up and down, and the separation tank 4 The upper outer wall is provided with a circular column 17, and the filter assembly of each layer is lapped between the circular column 17 and the liquid return tank 3 through the lap joint assembly (the filter assembly and the outer wall of the circular column 17 and the inner wall of the liquid return tank 3 can be Sealing is achieved by arranging existing structures such as rubber pads), the lap assembly includes a first fixing bar 11 and a second fixing bar 14, the first fixing bar 11 is evenly arranged on the outer wall of the circular column 17, and the second fixing bar 11 The bars 14 are evenly arranged on the inner wall of the liquid re...

Embodiment 3

[0043] like figure 1 and Image 6 As shown, it is basically the same as Example 1, except that the angle between the bottom surface of the liquid return tank 3 and the horizontal plane is 15°, the filter assembly is two layers, and the two layers of filter assemblies are distributed up and down, and the separation tank 4 The upper outer wall is provided with a circular column 17, and the filter assembly of each layer is lapped between the circular column 17 and the liquid return tank 3 through the lap joint assembly (the filter assembly and the outer wall of the circular column 17 and the inner wall of the liquid return tank 3 can be Sealing is achieved by arranging existing structures such as rubber pads), the lap assembly includes a first fixing bar 11 and a second fixing bar 14, the first fixing bar 11 is arranged in the outer wall of the circular column 17 and is connected with the circular ring The column 17 is rotatably connected, and the specific implementation is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com