Rapier loom control system based on embedded flexible PLC

A technology of rapier loom and control system, applied in general control system, control/adjustment system, loom and other directions, can solve the problems of high price of PLC system, increased maintenance cost in the later stage, and high technical requirements, and achieve the cost of later maintenance. Low cost, short development cycle, simple programmability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the present application.

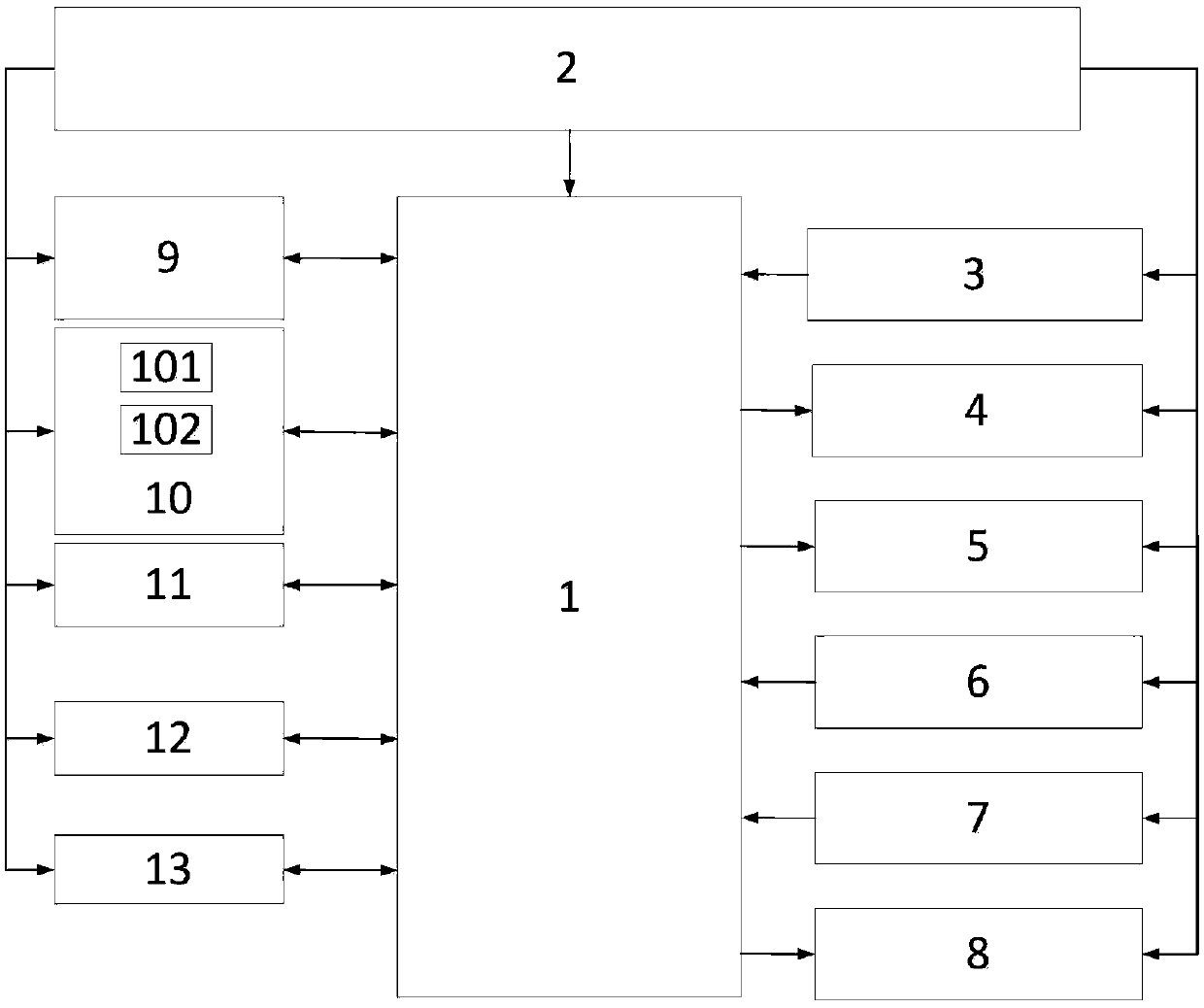

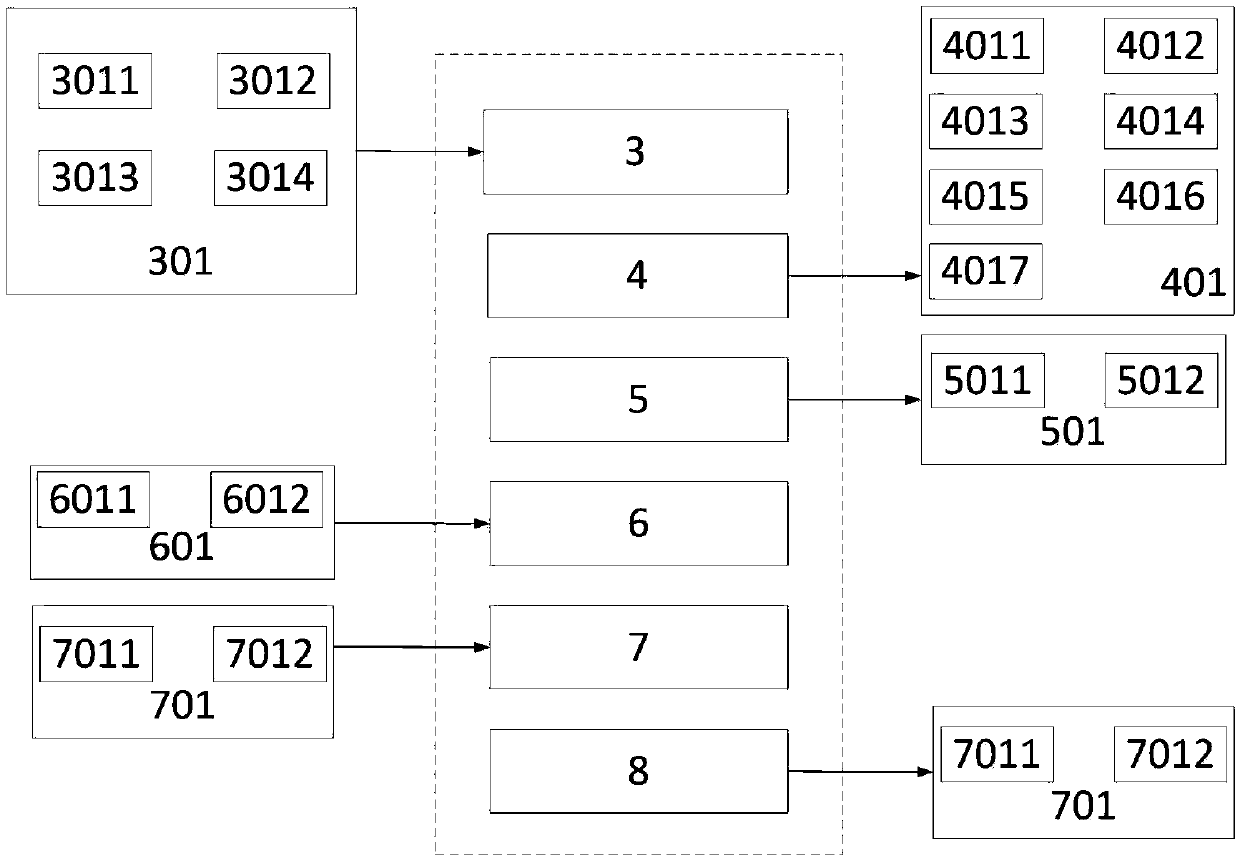

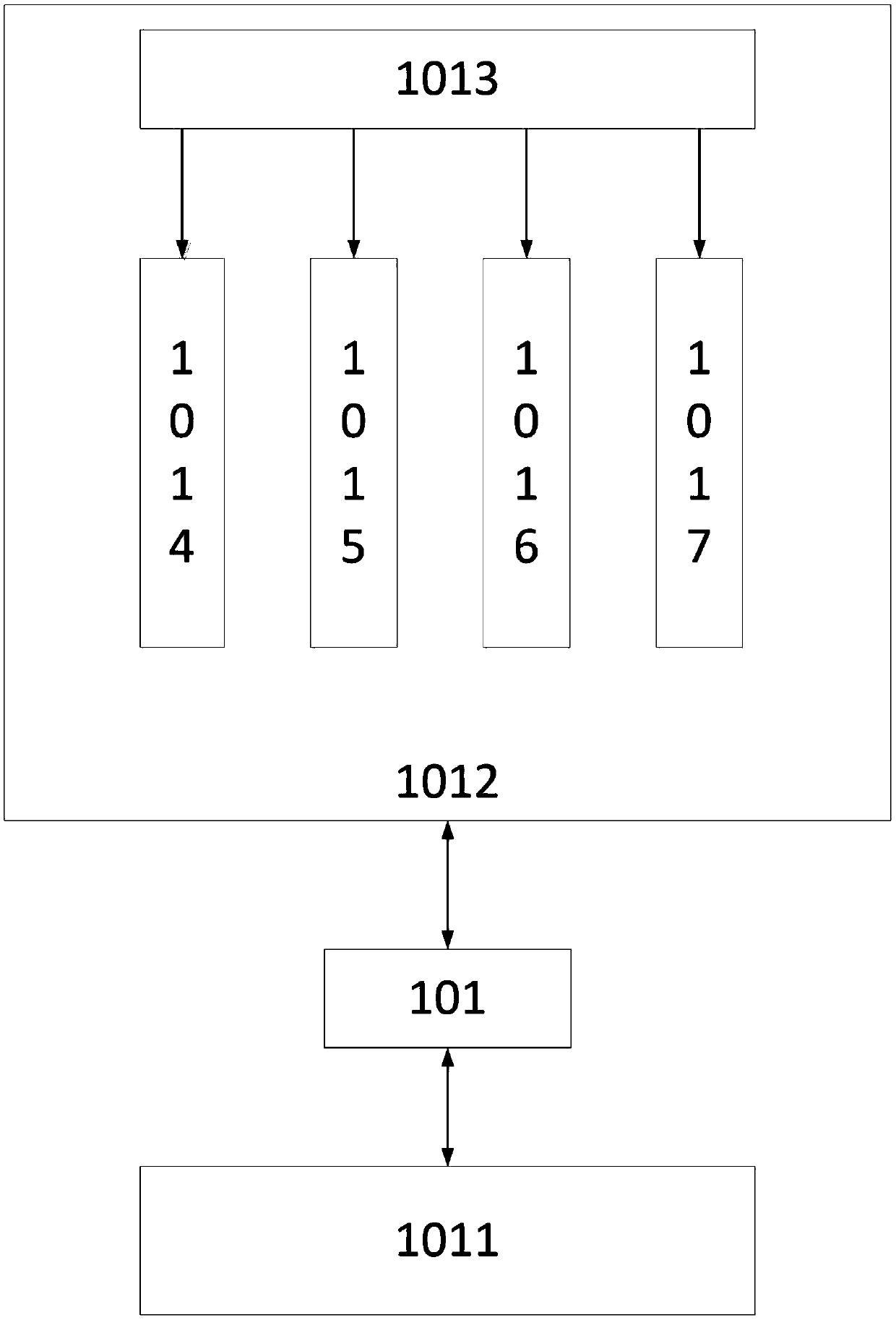

[0025]The rapier loom control system with embedded soft PLC of the present invention adopts a modular design, including a soft PLC development module and a multi-power conversion module (these power supplies include 24V DC power supplies, 12V, 5V, and 3.3V DC power supplies, and the setting method is The external access 24V DC power supply is converted into 12V, 5V, and 3.3V power supply by the multi-power conversion module inside the control system of the present invention.), common input module, common output module, high-speed signal transmission module, high-speed signal acquisition module, Analog input module, analog output module, Flash storage expansion module, communication interface module, SWD debugging module, Ethernet module and wireless modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com