Activation method of conductive carbon cloth and supercapacitor application of conductive carbon cloth

A technology of conductive carbon cloth and activation method, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., and can solve the problems of low electrochemical activity, small specific surface area, and low energy storage capacity of conductive carbon cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

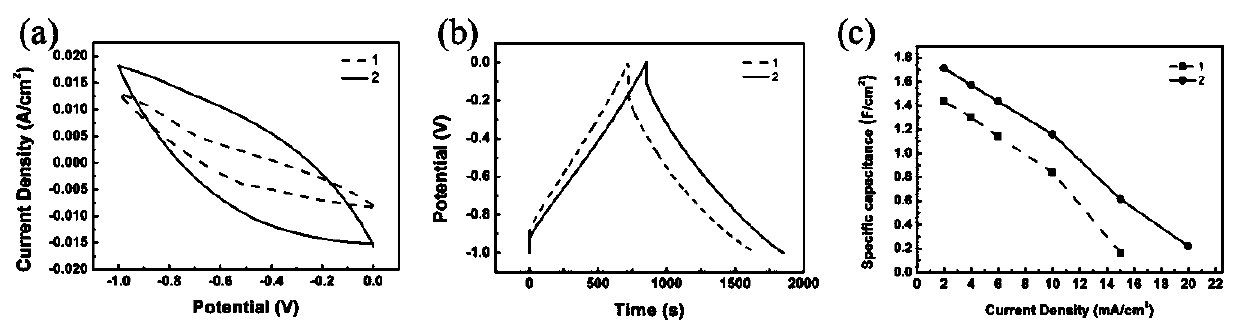

Embodiment 1

[0017] (1) Clean the conductive carbon cloth: place the carbon cloth in 3M hydrochloric acid, deionized water, acetone, and absolute ethanol solution for ultrasonic cleaning for 20 minutes, and then dry it for use;

[0018] (2) Activate conductive carbon cloth: configure 1M KOH solution as electrolyte, use conductive carbon cloth as working electrode, and platinum sheet as counter electrode, adopt the cyclic voltammetry method in the two-electrode system of the electrochemical workstation, and the potential range is -1 Conductive carbon cloth was treated under the conditions of ~-0.9V and scan rate of 10mV / s, and the time was 10s. The unactivated conductive carbon cloth is marked as 1, and the activated carbon cloth is marked as 2.

[0019] (3) This electrode is used as the negative electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode to form a three-electrode test system. With 1M KOH as the ...

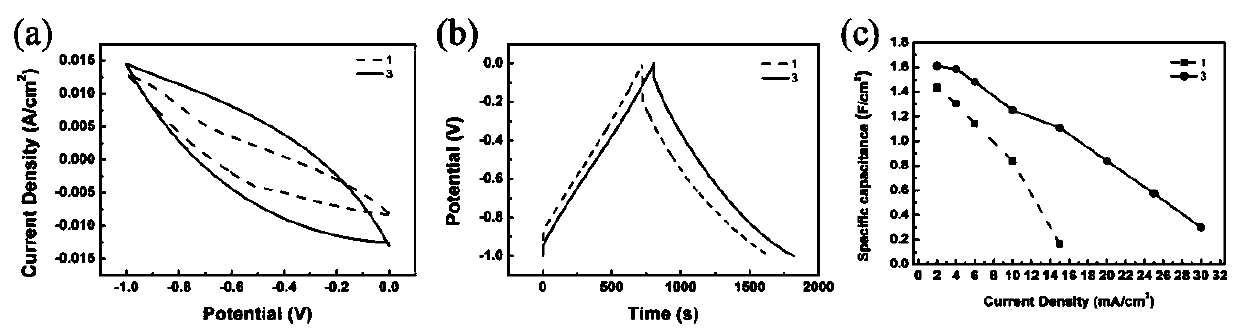

Embodiment 2

[0022] (1) Clean the conductive carbon cloth: place the carbon cloth in 3M hydrochloric acid, deionized water, acetone, and absolute ethanol solution for ultrasonic cleaning for 20 minutes, and then dry it for use;

[0023] (2) Activate conductive carbon cloth: configure 1M KOH solution as the electrolyte, use conductive carbon cloth as the working electrode, and platinum sheet as the counter electrode, adopt the cyclic voltammetry method in the two-electrode system of the electrochemical workstation, and the potential range is -0.9 The conductive carbon cloth was treated under the conditions of ~-0.8V and a scan rate of 10mV / s, and the time was 10s. The unactivated conductive carbon cloth is marked as 1, and the activated carbon cloth is marked as 3.

[0024] (3) Use this electrode as the negative electrode, use the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode to form a three-electrode test system, use 1MKOH as th...

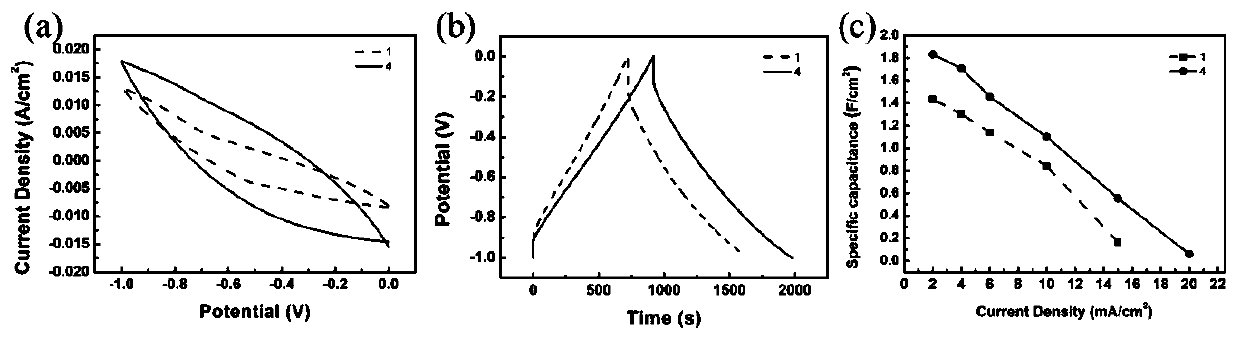

Embodiment 3

[0027] (1) Clean the conductive carbon cloth: place the carbon cloth in 3M hydrochloric acid, deionized water, acetone, and absolute ethanol solution for ultrasonic cleaning for 20 minutes, and then dry it for use;

[0028] (2) Activate conductive carbon cloth: configure 1M KOH solution as electrolyte, use conductive carbon cloth as working electrode, and platinum sheet as counter electrode, adopt the cyclic voltammetry method in the two-electrode system of the electrochemical workstation, and the potential range is -1 The conductive carbon cloth was treated under the conditions of ~-0.9V and a scan rate of 5mV / s, and the time was 20s. The unactivated conductive carbon cloth is marked as 1, and the activated carbon cloth is marked as 4.

[0029] (3) Use this electrode as the negative electrode, use the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode to form a three-electrode test system, use 1MKOH as the electrolyte, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com