A chromatographic column and its preparation method and application

A chromatographic column and column tube technology, applied in the field of analytical chemistry, can solve problems such as the difficulty of boron nitride coating, the failure of molecular sieve chromatographic column separation effect, etc., to avoid irreversible adsorption and adsorption of water, to solve the problem of poor separation effect, to solve Difficult to apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

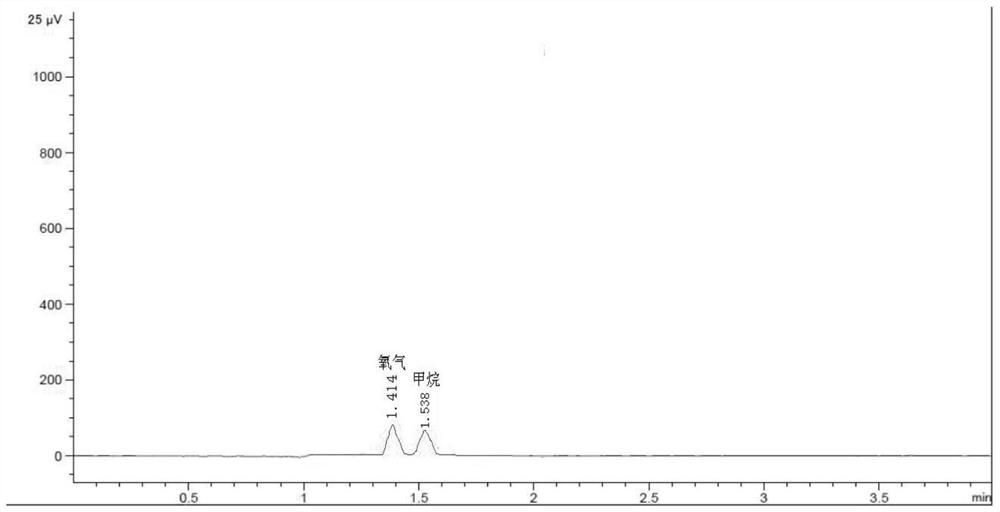

Embodiment 1

[0060] A chromatographic column, comprising a chromatographic column tube and a stationary phase coating coated on the inner wall of the chromatographic column tube, the chromatographic column tube is a quartz capillary column tube, and the stationary phase coating is composed of a porous polymer and a boron nitride inorganic adsorbent. Porous polymers are produced by reacting styrene and divinylbenzene as polymer monomers. The boron nitride inorganic adsorbent in this embodiment is encapsulated in the pores of the porous polymer.

[0061] Preparation of the column:

[0062] Pretreatment quartz capillary column tube: Prepare a quartz capillary column tube with a length of 30m and an inner diameter of 0.53mm, rinse the inner wall of the quartz capillary column tube with 3mol / L hydrofluoric acid solution, and then rinse the inner wall of the quartz capillary column tube with distilled water At least once, until it is cleaned, then place the quartz capillary column tube in an ag...

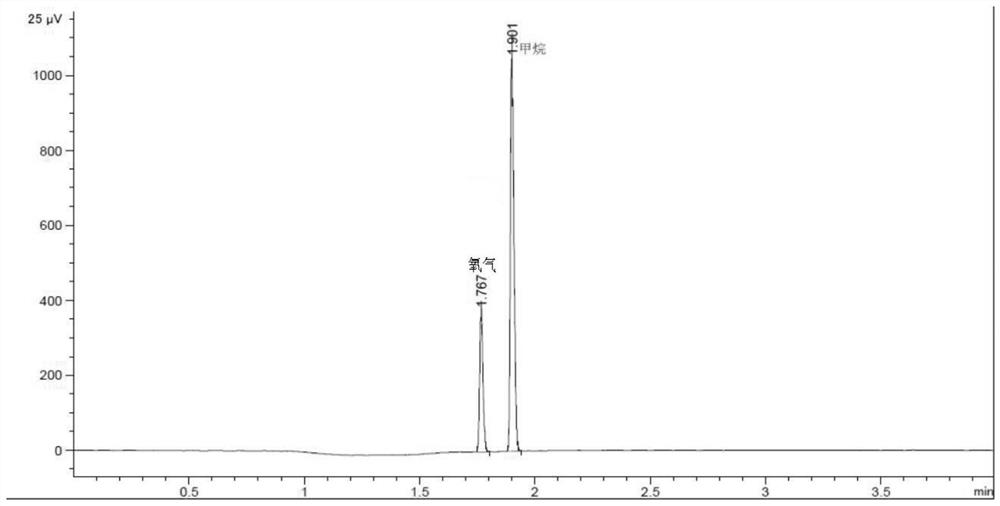

Embodiment 2

[0081] A chromatographic column, comprising a chromatographic column tube and a stationary phase coating coated on the inner wall of the chromatographic column tube, the chromatographic column tube is a quartz capillary column tube, and the stationary phase coating is composed of a porous polymer and a boron nitride inorganic adsorbent. Porous polymers are produced by reacting styrene and divinylbenzene as polymer monomers. The boron nitride inorganic adsorbent in this embodiment is encapsulated in the pores of the porous polymer. The boron nitride inorganic adsorbent used in this example is porous boron nitride.

[0082] Preparation of the column:

[0083] Pretreatment quartz capillary column tube: Prepare a quartz capillary column tube with a length of 50m and an inner diameter of 0.32mm, rinse the inner wall of the quartz capillary column tube with 2mol / L hydrofluoric acid solution, and then rinse the inner wall of the quartz capillary column tube with distilled water for ...

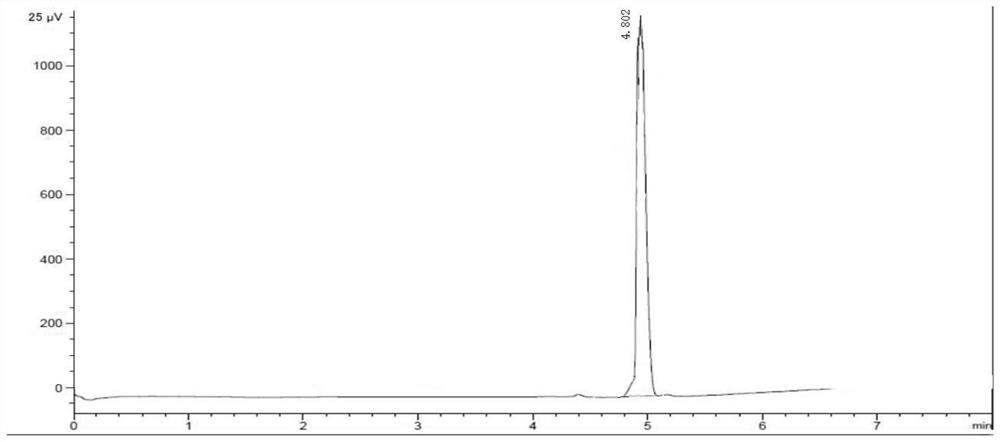

Embodiment 3

[0096] A chromatographic column, comprising a chromatographic column tube and a stationary phase coating coated on the inner wall of the chromatographic column tube, the chromatographic column tube is a quartz capillary column tube, and the stationary phase coating is composed of a porous polymer and a boron nitride inorganic adsorbent. Porous polymers are produced by reacting styrene and divinylbenzene as polymer monomers. The boron nitride inorganic adsorbent is encapsulated in the pores of the porous polymer. The boron nitride inorganic adsorbent used in this example is porous boron nitride.

[0097] Preparation of the column:

[0098] Pretreatment quartz capillary column tube: Prepare a quartz capillary column tube with a length of 40m and an inner diameter of 0.25mm, rinse the inner wall of the quartz capillary column tube with 3mol / L hydrofluoric acid solution, and then rinse the inner wall of the quartz capillary column tube with distilled water At least once until it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com