Preparation technology of harpoon-shaped terminal for connector

A preparation process and harpoon-shaped technology, which is applied in the field of connector component preparation technology, can solve the problems of difficult processing and low yield of finished products, and achieve the effects of smooth wiring process, high yield of finished products, and guaranteed service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

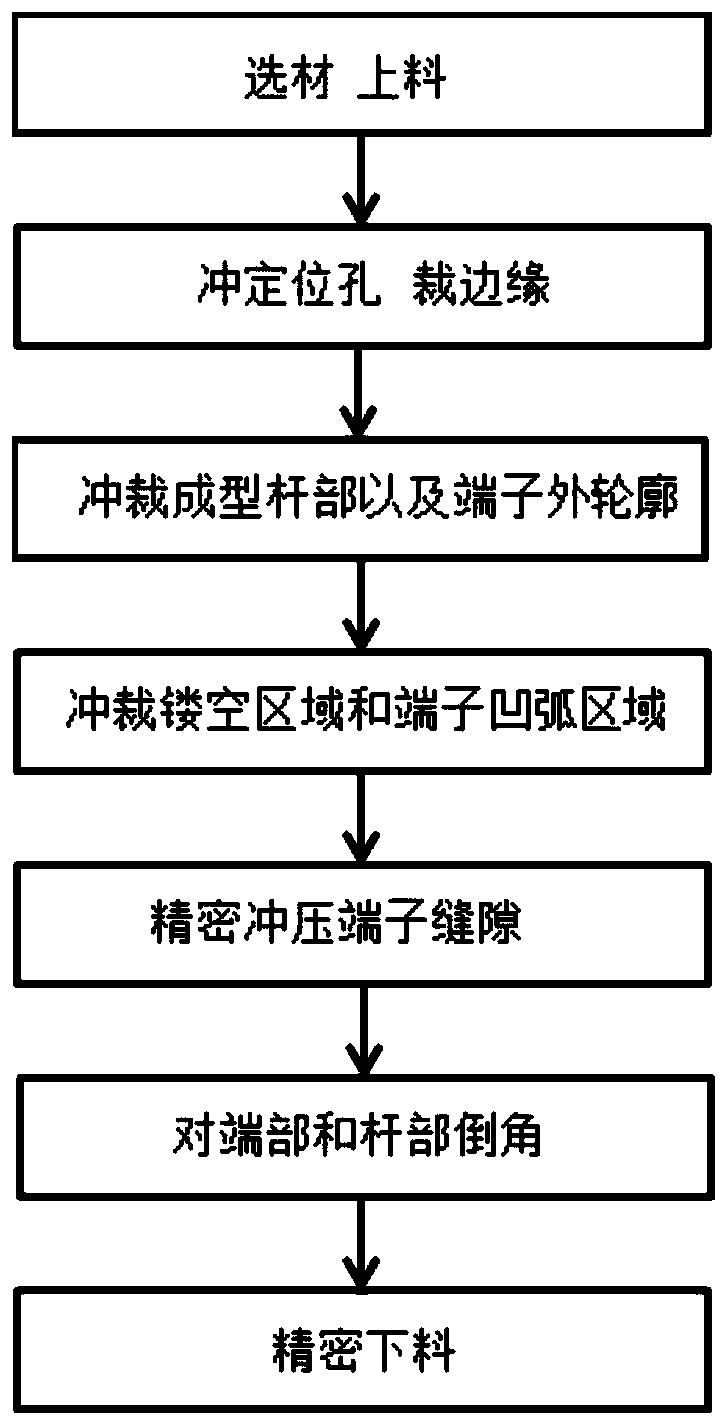

[0024] Preparation process of harpoon terminals for connectors, see figure 1 , including the following steps:

[0025] S1: Choose a long strip of raw material, and put the raw material into the starting position of the punching machine, the thickness of the raw material is 0.25-0.45mm.

[0026] S2: Punch out positioning holes on both sides of the raw material board, and cut off excess edge material on the raw material board.

[0027] S3: Punch out the stem of the harpoon-shaped terminal, and punch out the rectangular outline of the terminal through a rectangular frame die; the punching process first obtains the general outline of the stem by sectioning, and then removes the end by trimming Burrs on the edges of the head and stem. The punching process is carried out by a precision punching hydraulic press, so that the ring gear on the guide plate is pressed into the metal sheet near the cutting edge of the die, and then the punching force acts on the sheet under the condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com