A fully automatic electric blanket wiring compound machine

A fully automatic, electric blanket technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of inability to achieve complete automation, inability to realize automated wiring, low degree of automation, etc., to improve processing production efficiency and degree of automation. High, continuous and uninterrupted effect of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

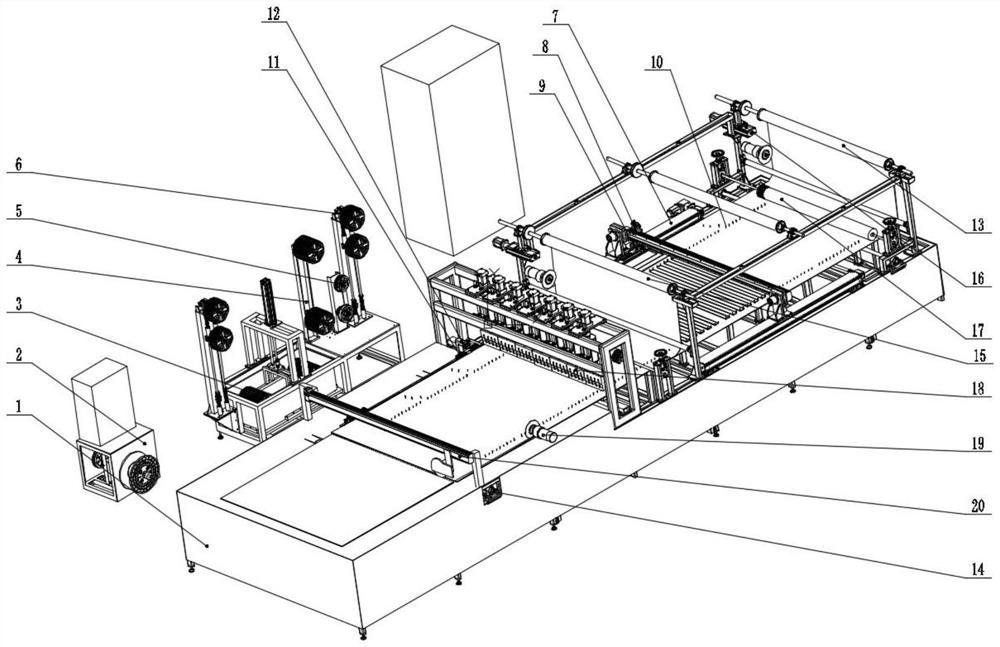

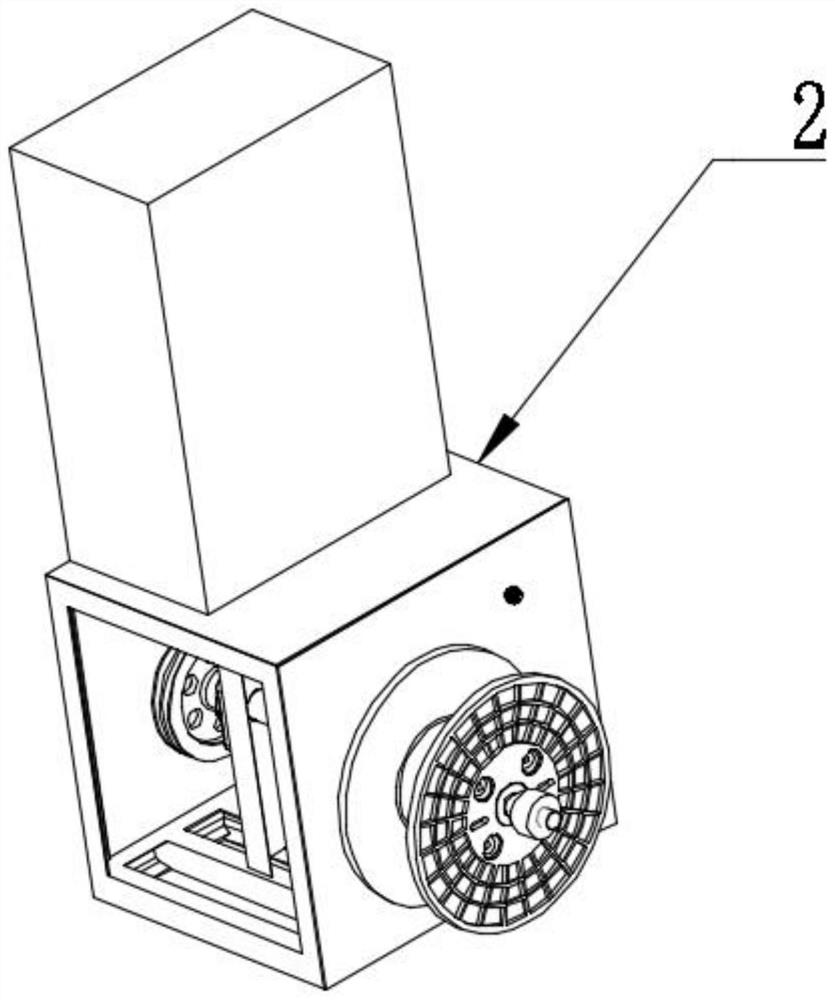

[0040] In this embodiment, a fully automatic electric blanket wiring composite machine is specifically provided, including a main frame 1, which is used as the main body of each component in the technical solution, and a cloth transmission channel is provided on the main frame 1, and the cloth is The transmission channel is mainly used to transmit non-woven fabrics, and the non-woven fabrics are processed into electric blankets.

[0041] Such as figure 1 , Figure 10 As shown, several threading needles 10 are arranged on the cloth conveying channel, and each threading needle 10 is divided into two rows arranged in parallel and located in the cloth conveying channel, and each threading needle 10 is used to constrain the wiring path of the heating wire, and along the In the transmission direction of the cloth transmission channel, a first cloth releasing device 13, a wiring module 7, a second cloth releasing device 15 and an ultrasonic composite device 18 are sequentially arran...

Embodiment 2

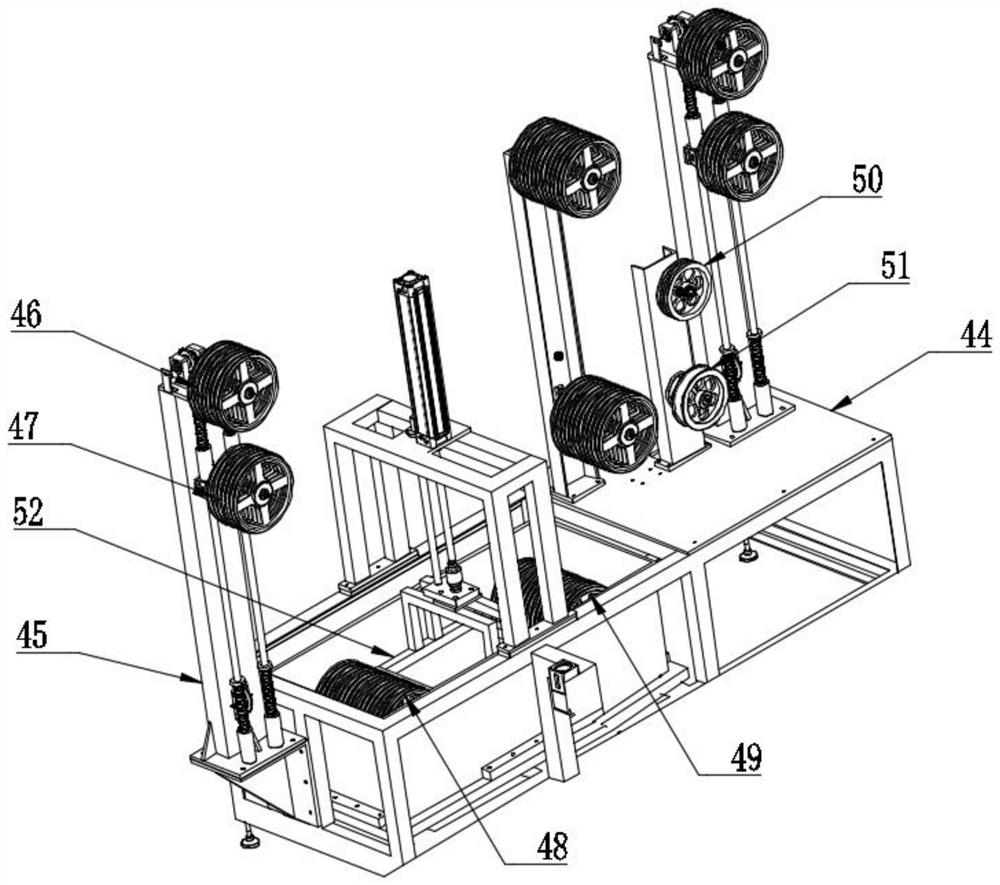

[0065] On the basis of Embodiment 1, the following structure can also be used to realize the operation of automatic clamping and automatic clamping, such as Figure 9 As shown, the details are as follows: the passive clip release device 11 includes a clip body 31 and a clip seat 32 arranged on the transmission chain 30, and a clip corresponding to the clip seat 32 is slidably provided on the clip body 31. Head 33, collet 33 is pressed against on described clip seat 32 by thrust spring under initial state, is hinged with toggle lever 34 on clamp body 31 and toggle lever 34 is equipped with the torsion spring that drives its reset, toggles The rotating movement of the rod 34 is linked to the slide of the collet 33; one end of the toggle rod 34 is arranged between the collet 33 and the clamp seat 32, and the other end is fastened in the reserved groove of the collet 33; The automatic clamping device 12 includes a driving seat 38 mounted on the main frame 1 and a gear 39 rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com