Double-bond polymer quantum dot film and preparation method thereof

A quantum dot film and polymer technology, applied in chemical instruments and methods, electronic equipment, other household appliances, etc., can solve the problems of quantum dot luminescence distortion, difficulty in barrier film, high cost, and reduce the range of edge failure, Strong practicability and the effect of improving the barrier capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

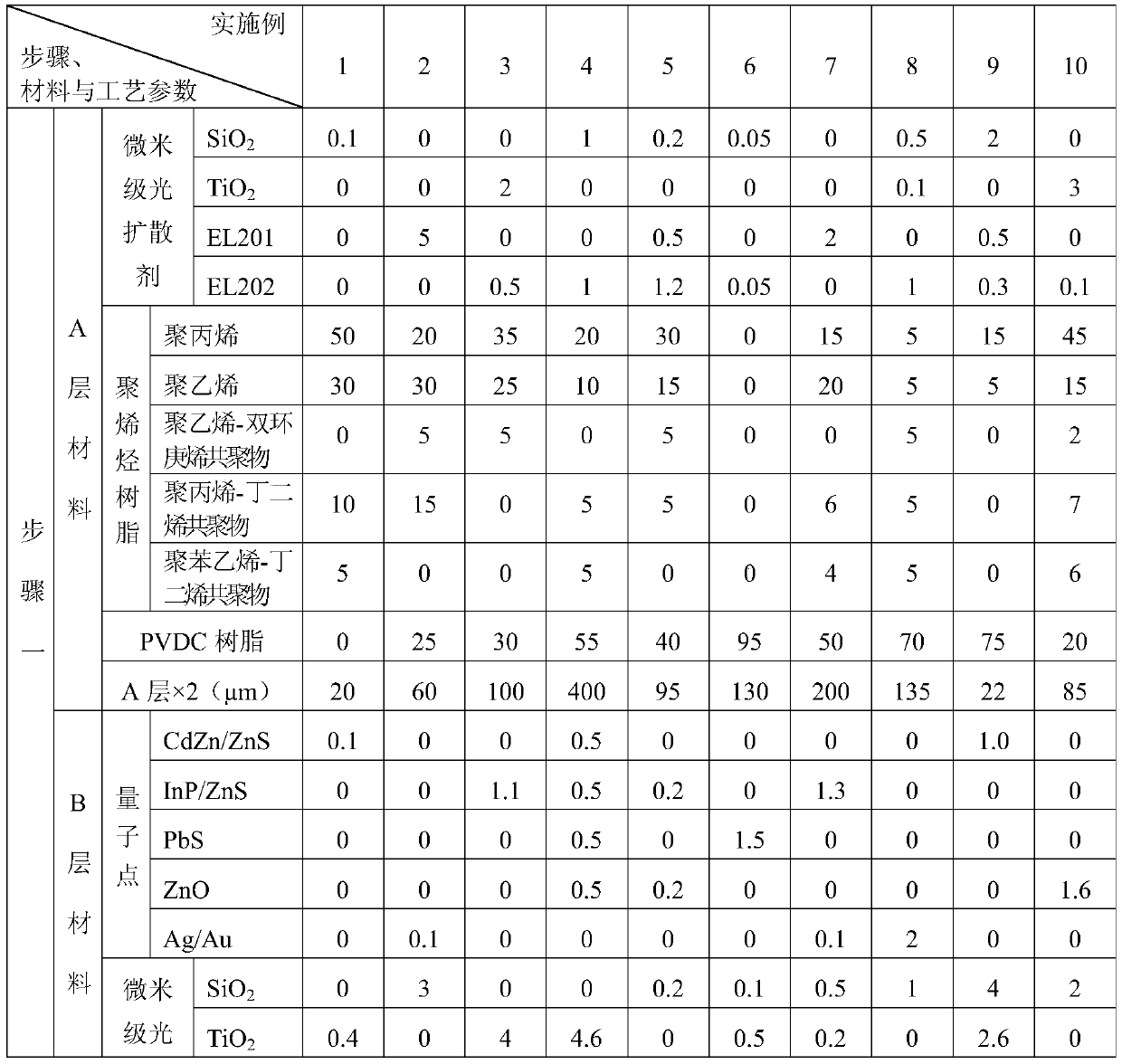

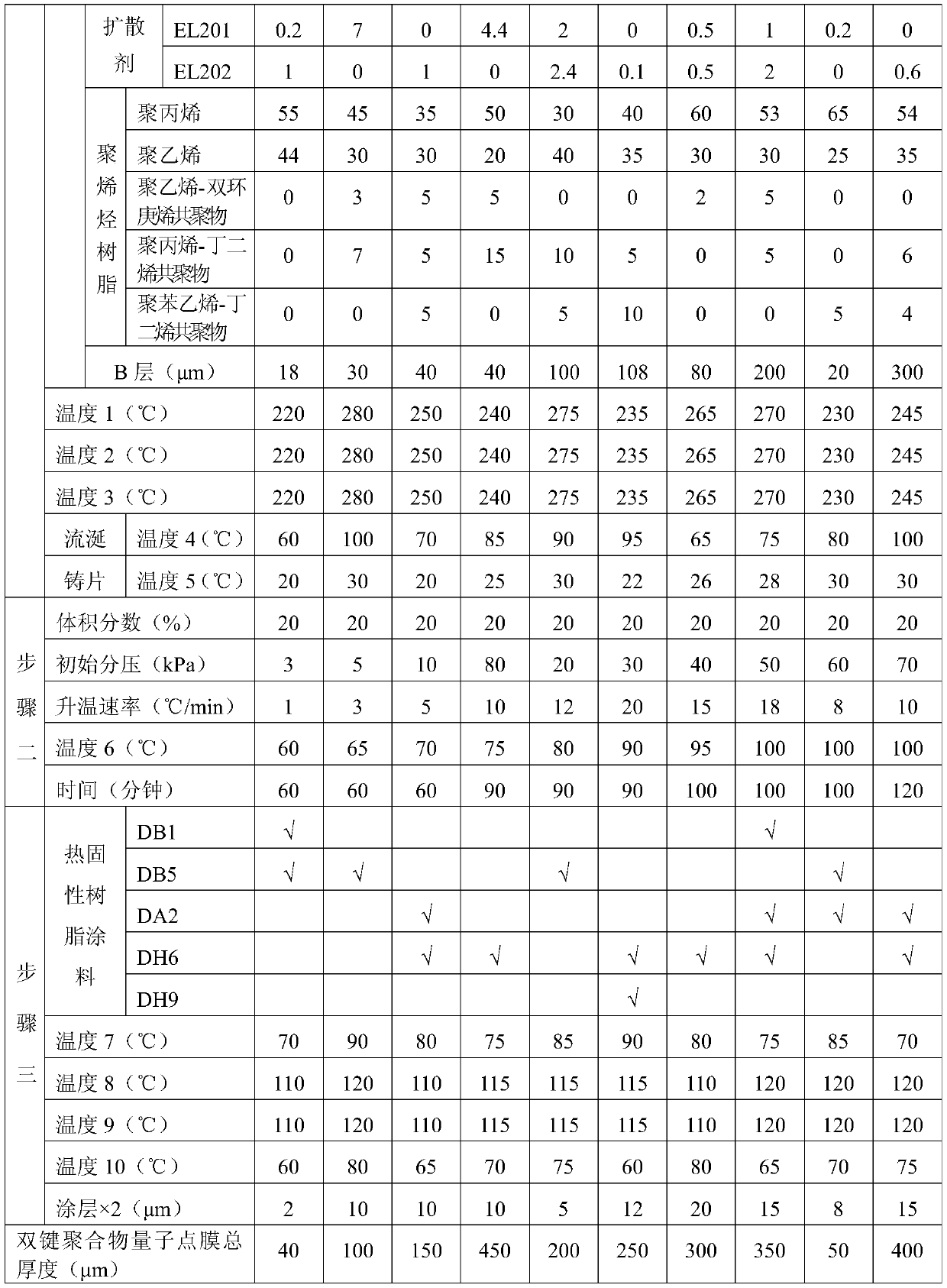

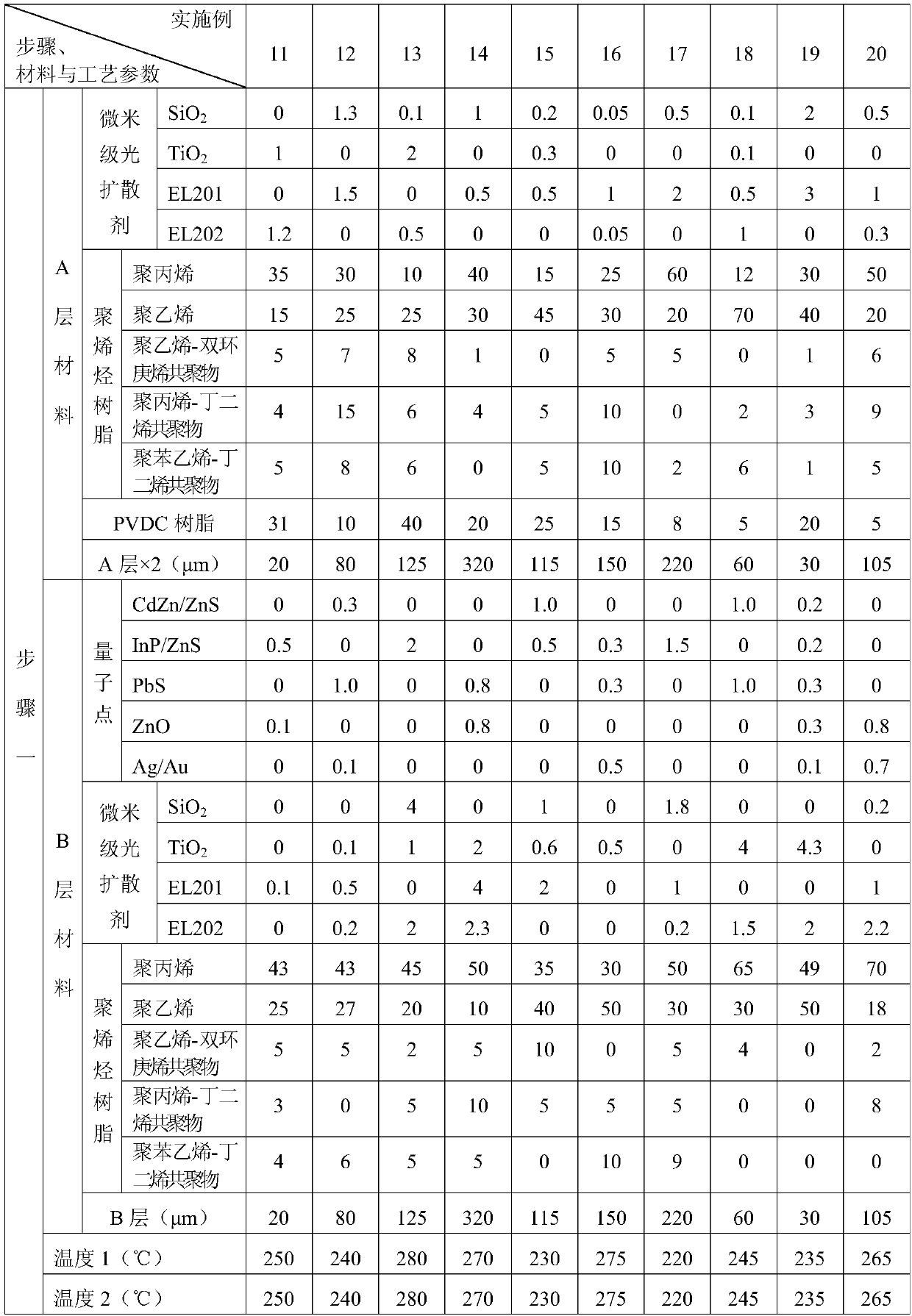

[0034] 1. Embodiments 1-20: a method for preparing a double-bond polymer quantum dot film, the steps are:

[0035] Step a: First blend 0.1-5 parts by mass of micron-scale light diffusing agent, 0-95 parts by mass of polyolefin resin and 0-95 parts by mass of vinylidene chloride-methyl acrylate copolymer (ie PVDC resin) A layer material, and then 0.02 to 2 mass parts of quantum dots and 0.1 to 10 mass parts of micron light diffusing agent and 80 to 99 mass parts of polyolefin resin are blended into B layer material; the A layer material and B After the layer material is melted at 220°C to 280°C (temperature 1) in extruder 1 and 220°C to 280°C (temperature 2) in extruder 2, it is heated through 220°C to 280°C (temperature 3) ) under the three-layer co-extrusion die mouth extrusion, drool on the cold drum at 60 ~ 100 ℃ (temperature 4) to make an ABA structure film with a thickness of A layer of 10 ~ 200 μm and a thickness of B layer of 18 ~ 300 μm or in Cast sheet on cold drum a...

Embodiment 21

[0057] A double-bond polymer quantum dot film, the double-bond polymer quantum dot film is made of A-layer material and B-layer material through three-layer co-extrusion salivation or biaxial stretching, the thickness of A layer is 10 μm, and the thickness of B layer A quantum dot primary base film with a 300 μm ABA three-layer film structure, and then fluorinated on both surfaces of the quantum dot primary base film to prepare a quantum dot secondary base film with an ABA three-layer film structure, and then in Double-bond polymer quantum dot film prepared by coating thermosetting resin on both surfaces of the quantum dot secondary base film and forming a coating with a drying thickness of 1 μm;

[0058] The A-layer material is a mixture of 0.1 parts by mass of micron-scale light diffusing agent and 95 parts by mass of vinylidene chloride-methyl acrylate copolymer (PVDC resin for short);

[0059] The B layer material is composed of 0.02 parts by mass of quantum dots, 0.1 part...

Embodiment 22

[0063] A double-bond polymer quantum dot film, the double-bond polymer quantum dot film is made of A-layer material and B-layer material through three-layer co-extrusion salivation or biaxial stretching, and the thickness of A layer is 200 μm, and the thickness of B layer is A quantum dot primary base film with an ABA three-layer film structure of 18 μm, and then fluorinated on the double surface of the quantum dot primary base film to prepare a quantum dot secondary base film with an ABA three-layer film structure. Double-bond polymer quantum dot film prepared by coating thermosetting resin on both surfaces of the quantum dot secondary base film and forming a coating with a drying thickness of 10 μm;

[0064] The A-layer material is a mixture of 5 parts by mass of micron-scale light diffusing agent and 95 parts by mass of polyolefin resin;

[0065] The B layer material is composed of 2 parts by mass of quantum dots, 10 parts by mass of micron light diffusing agent and 99 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com