Reflective sheet protection glue and reflective sheet protection glue tape, and preparation methods thereof

A technology for protective tapes and reflective sheets, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc. problem, to achieve the effect of easy fit, stable physical properties, and not easy to fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

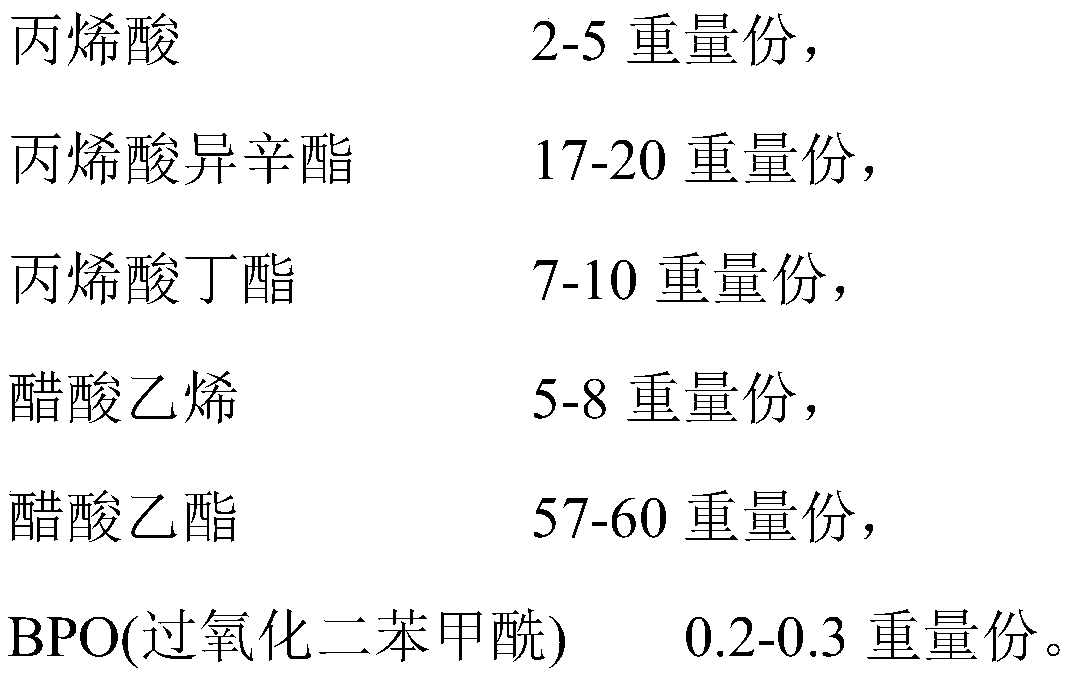

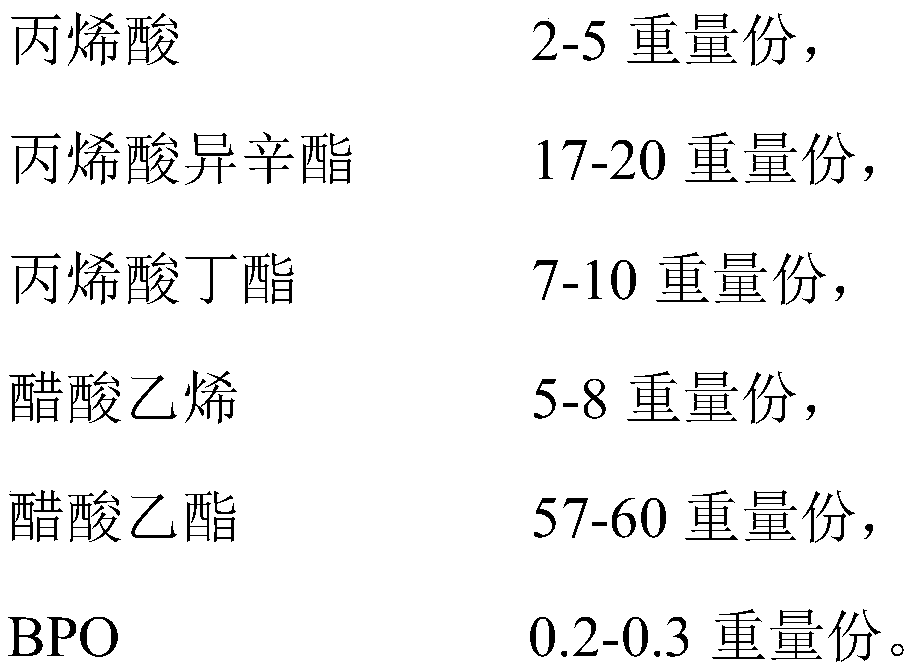

[0027] A preparation method for reflective film protective tape, comprising the following steps:

[0028] Step 1: mixing 2 parts by weight of acrylic acid, 17 parts by weight of isooctyl acrylate, 7 parts by weight of butyl acrylate, 5 parts by weight of vinyl acetate and 49 parts by weight of ethyl acetate;

[0029] Step 2: Turn on the mixer, control the speed at 25 rpm, heat up to 80°C, start titration of the titration solution prepared by 0.2 parts by weight of BPO and 8 parts by weight of ethyl acetate, titrate for 20 minutes, and the temperature rises to 85°C, stop titration;

[0030] Step 3: Start to cool down, and continue titration when the temperature drops to 80°C. It takes 100 minutes. After titration, keep warm for 4 hours to cool down and remove the glue; get the protective glue for the finished reflector;

[0031] Step 4: Unglue: put 5 parts by weight of modified terpene phenol resin and 5 parts by weight of carbon 9 resin into 100 parts by weight of protective ...

Embodiment 2

[0034] A preparation method for reflective film protective tape, comprising the following steps:

[0035] Step 1: mixing 5 parts by weight of acrylic acid, 20 parts by weight of isooctyl acrylate, 10 parts by weight of butyl acrylate, 8 parts by weight of vinyl acetate and 52 parts by weight of ethyl acetate;

[0036] Step 2: Turn on the mixer, control the speed at 25 rpm, heat up to 80°C, start titration of the titration solution prepared by 0.3 parts by weight of BPO and 8 parts by weight of ethyl acetate, titrate for 20 minutes, and the temperature rises to 86°C, stop titration;

[0037] Step 3: Start to cool down, and continue titration when the temperature drops to 80°C. It takes 100 minutes. After titration, keep warm for 4 hours to cool down and remove the glue; get the protective glue for the finished reflector;

[0038] Step 4: Unglue: put 5 parts by weight of modified terpene phenol resin and 5 parts by weight of carbon 9 resin into 100 parts by weight of protective...

Embodiment 3

[0041] A preparation method for reflective film protective tape, comprising the following steps:

[0042] Step 1: Mix 3.5 parts by weight of acrylic acid, 18.5 parts by weight of isooctyl acrylate, 8.5 parts by weight of butyl acrylate, 6.5 parts by weight of vinyl acetate and 50.5 parts by weight of ethyl acetate;

[0043] Step 2: Turn on the mixer, control the speed at 25 rpm, heat up to 80°C, start titration of the titration solution prepared by 0.25 parts by weight of BPO and 8 parts by weight of ethyl acetate, titrate for 20 minutes, and the temperature rises to 85.5°C, stop titration;

[0044] Step 3: Start to cool down, and continue titration when the temperature drops to 80°C. It takes 100 minutes. After titration, keep warm for 4 hours to cool down and remove the glue; get the protective glue for the finished reflector;

[0045] Step 4: Unglue: put 5 parts by weight of modified terpene phenol resin and 5 parts by weight of carbon 9 resin into 100 parts by weight of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com