Glass chamfering machine

A chamfering machine and glass technology, applied in the direction of grinding frame, grinding machine parts, machine tools suitable for grinding workpiece edges, etc., can solve the problem of corrosion of screw parts, affecting the working stability of the glass chamfering machine, It is not easy to maintain and repair problems, and achieve the effect of easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

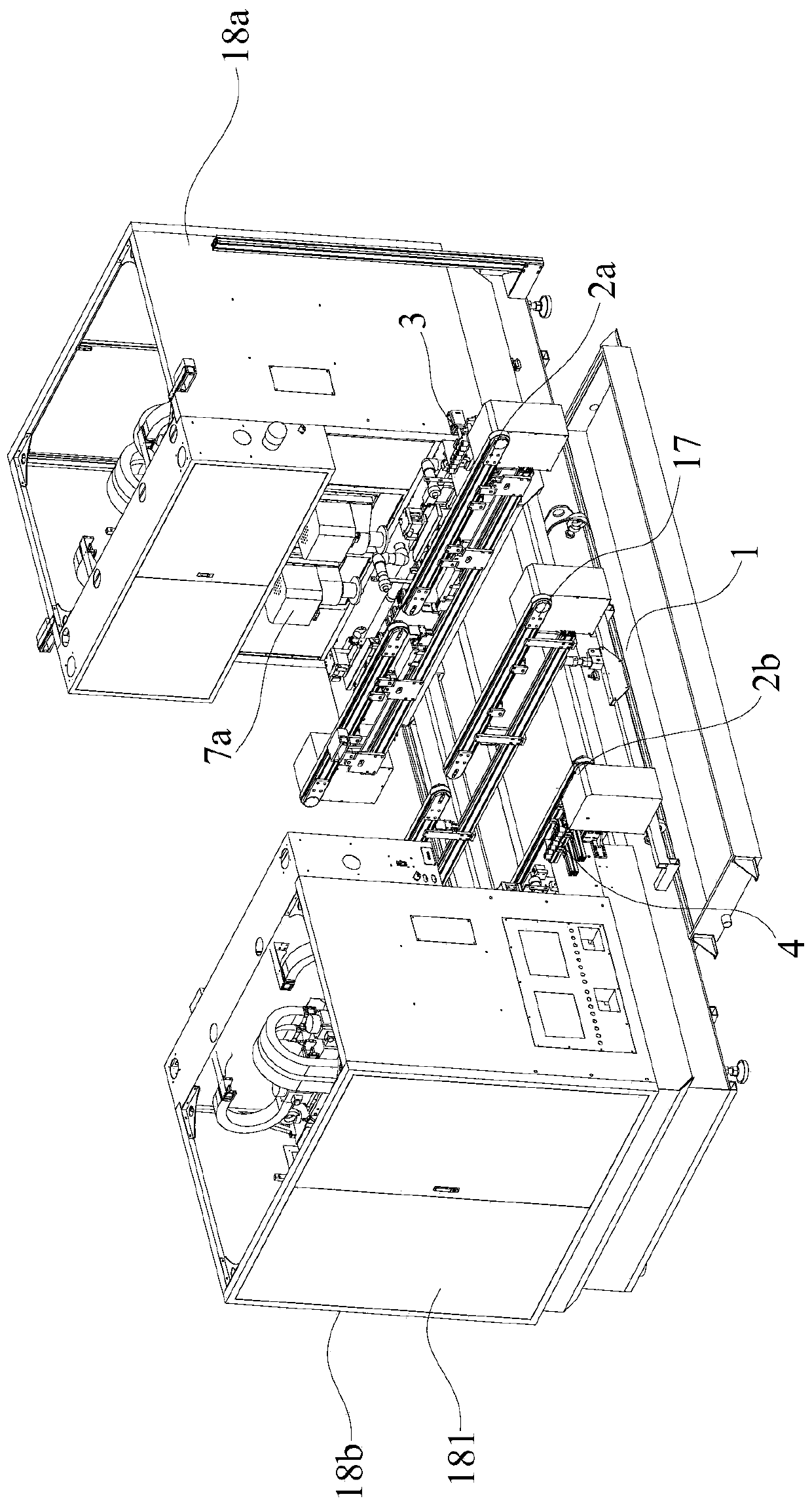

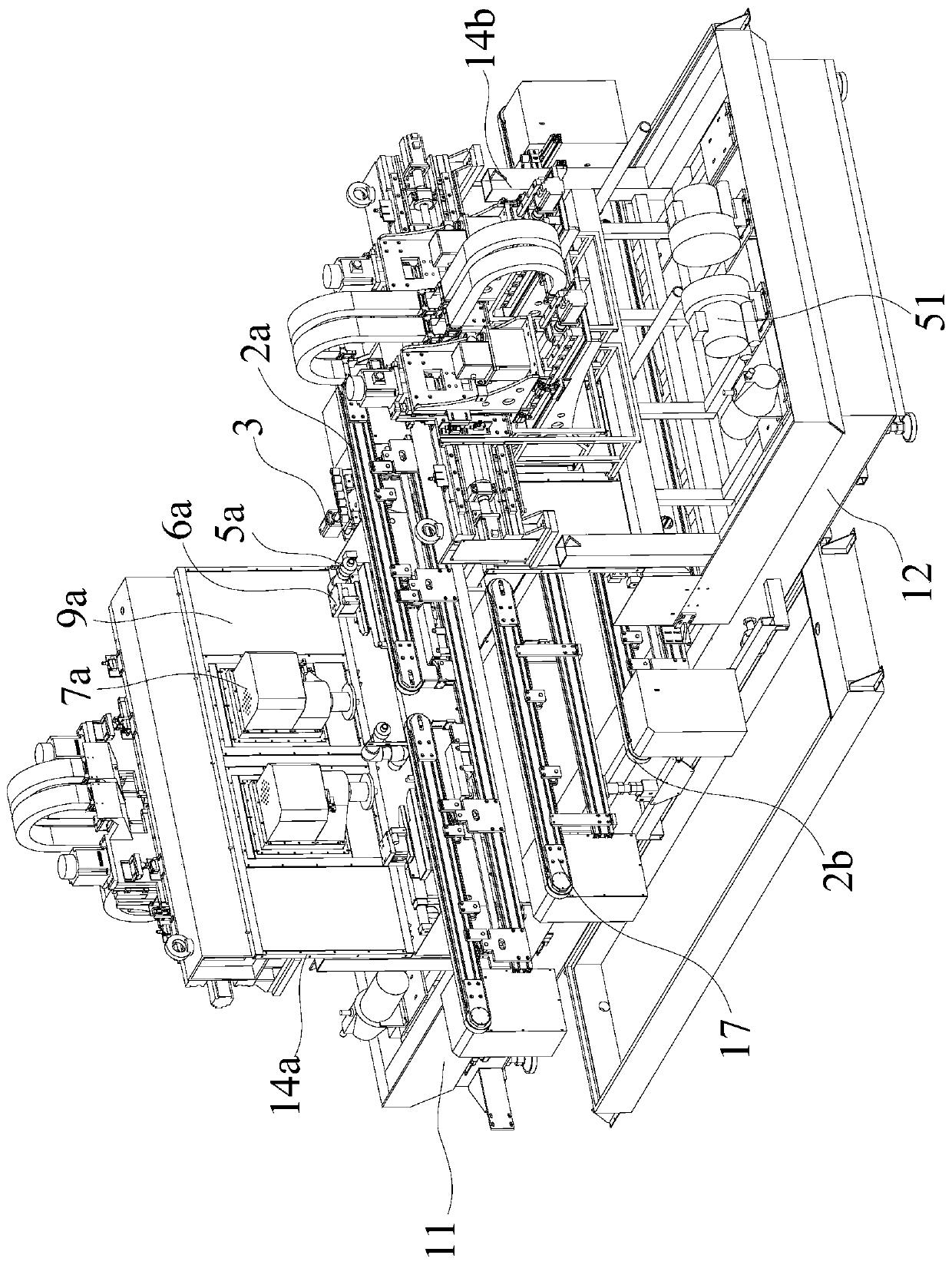

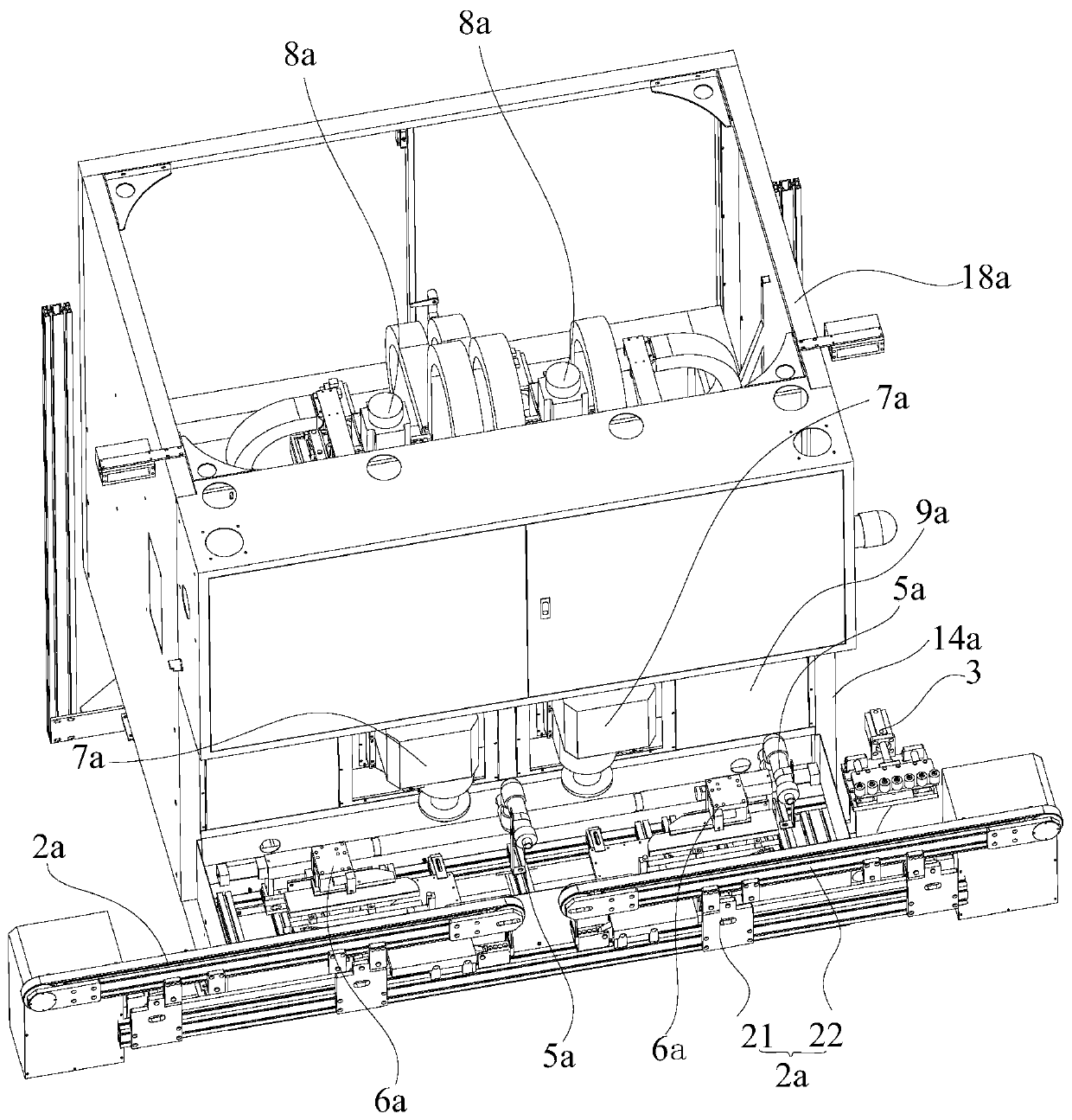

[0034] The present invention will be further described below in conjunction with the examples, which are preferred embodiments of the present invention.

[0035] Such as Figure 1-16 As shown, a glass chamfering machine includes a base 1 and a driving frame 11 and a driven frame 12 that are relatively arranged on the base 1, and the driving frame 11 is driven by a frame driving mechanism 13 It is close to or far from said driven frame 12 . The driving frame 11 and the driven frame 12 are respectively provided with several liftable conveyor belt mechanisms 2a and 2b, and the conveyor belt mechanisms 2a and 2b transport glass along the X-axis direction. The feeding end of the conveyor belt mechanism 2a on the active frame 11 is provided with an active positioning device 3 . A driven positioning device 4 is provided at the feeding end of the conveyor belt mechanism 2 b on the driven frame 12 . Air blowing devices 5a and 5b and glass clamping and positioning devices 6a and 6b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com