A method of microwave/hydrogen peroxide treatment of cow dung fermentation biogas slurry

A technology of hydrogen peroxide and microwave catalytic oxidation, which is applied in the fields of oxidized water/sewage treatment, light water/sewage treatment, animal husbandry wastewater treatment, etc. , High processing efficiency, the effect of reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

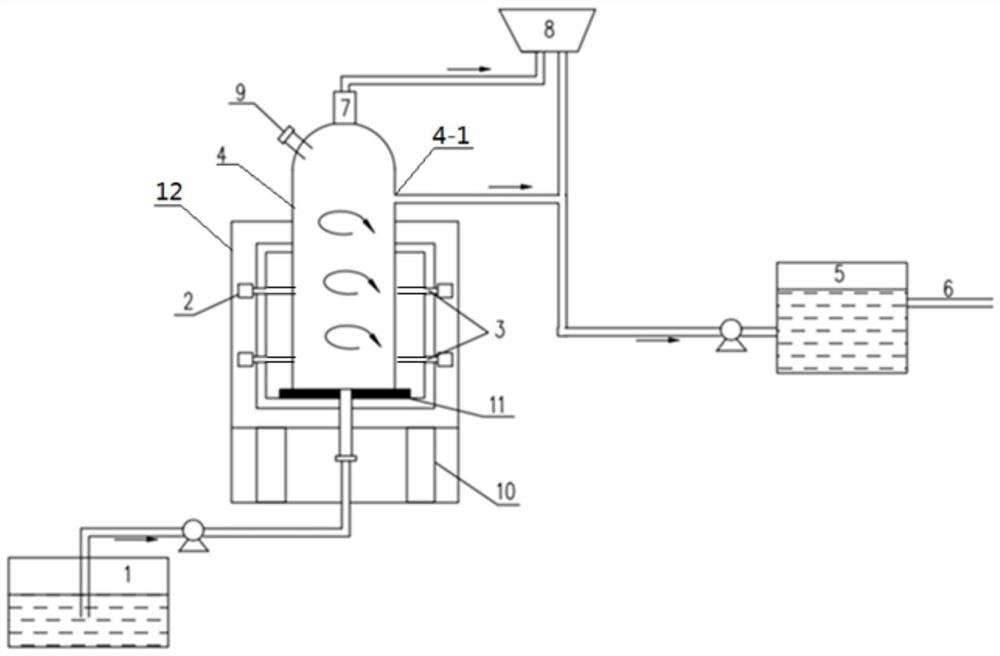

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: a kind of method of microwave / hydrogen peroxide treatment cow dung fermented biogas liquor in this embodiment, specifically carry out according to the following steps:

[0026] 1. Preheating stage: the biogas slurry is preheated to 40-50°C through a microwave reactor;

[0027] 2. Microwave / hydrogen peroxide treatment: use inorganic acid to adjust the pH of the biogas slurry treated in step 1 to 3, and then add H 2 o 2 , put it under microwave conditions, stir at the same time, keep for 4-5 minutes, turn off the microwave source, take it out, and let it stand at room temperature for 1-1.5 hours, and complete the method of microwave / hydrogen peroxide treatment of cow dung fermentation biogas slurry.

specific Embodiment approach 2

[0028]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the power of the microwave reactor in Step 1 is 300W. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step two, the inorganic acid is concentrated sulfuric acid with a mass concentration of 98%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com